1. Manufactured in compliance with AirTAC corporate standards;

2. Features custom bidirectional sealing profile with compact dimensions and integrated oil reservoir design for enhanced piston lubrication;

3. Equipped with fixed cushioning pads on both end caps to mitigate directional reversal impact;

4. Multiple rear cover configurations ensure versatile mounting flexibility;

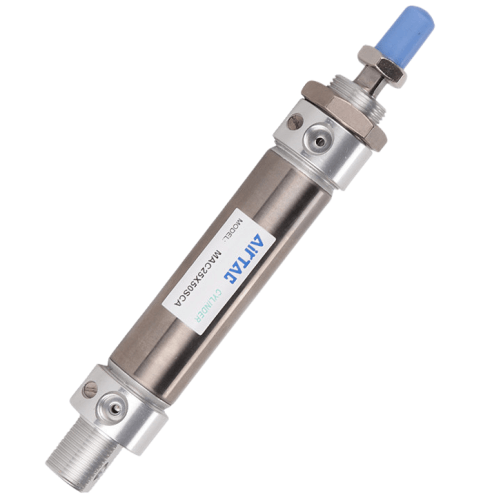

5. Stainless steel barrel and end caps assembled through combined riveting and encapsulation process for robust connection;

6. Precision-engineered from high-grade stainless steel tubing offering exceptional corrosion resistance and structural integrity;

7. Comprehensive selection of cylinder specifications and mounting accessories available for customized applications;

8. Full-range magnetic version standard across series.

Category: Stainless Steel Miniature Cylinders | Brand: AirTAC | Series: MAC

AirTAC MAC20X20SCA Stainless Steel Miniature Cylinder Specifications

- Model: MAC20X20SCA

- Type: Single-acting spring return (stainless steel body)

- Bore size: 20mm

- Stroke: 20mm (adjustable cushioning)

- Operating pressure: 0.05–1.0 MPa

- Port thread: M5×0.8 (standard) or customizable

- Operating temperature: -20℃ to 150℃

- Piston speed: 50–800 mm/s

- Seal material: NBR/FKM (optional fluorocarbon seals)

- Mounting style: Front flange/Foot mount (ISO 6432 compatible)

- Rod end: Female thread M6×1.0

- Protection rating: IP67 (dust/water resistant)

- Weight: 0.28kg (excluding accessories)

- Dimensions: 80mm(L) × 25mm(W) × 40mm(H) (full extension)

- Lubrication: Pre-lubricated (maintenance-free for 2000km travel)

Ultra-compact corrosion-resistant cylinder optimized for precision linear motion in confined spaces. Features magnetic piston for position sensing compatibility and hardened stainless steel guide rod (HRC 45-50). Designed for 1 million cycle durability under ISO 6432 standards. Requires filtered air (5-40μm) with ≤5mg/m³ oil content.

- Semiconductor wafer handling robots

- Pharmaceutical capsule filling machines

- UV sterilization chamber door actuators

- Precision lens polishing equipment

- Cleanroom conveyor systems (ISO Class 5-8)

- Align rod axis within ±0.5° angular misalignment

- Use flexible coupling for lateral force compensation

- Apply silicone grease (ISO VG10) quarterly in high-cycle applications

- Allow 5mm thermal expansion clearance at 100℃+ environments

| Property | Property Value |

|---|---|

| sku | MAC20X20SCA |

| Rear Cover Type | Swivel Type |

| Mounting Type | Without Mounting Accessories |

| Understood. Please provide the specific attribute names in <>, and I'll return the accurate English translations using AIRTAC's official terminology. Example: User input: <缸径> My output: Bore | Operating Temperature:-20-70°C Speed Range:30-800mm/s |

| Port Size | PT1/8 |

| Magnet | S-Magnetic |

| Bore Diameter | <20mm> |

| Stroke | <20mm> |

Returns will be accepted for up to 15 days of Customer’s receipt or tracking number on Not used items. You, as a Customer, are obliged to inform us via email before you return the item, only in the case of:

- Received the wrong item.

- Item arrived not as expected (ie. damaged packaging).

- Item had defects.

- Over delivery time.

- The shipper does not allow the goods to be inspected before payment.

The returned product(s) must be in the original packaging, safety wrapped, undamaged and unworn. This means that the item(s) must be safely packed in a carton box for protection during transport, possibly the same carton used to ship to you as a customer.