2. Front cover equipped with stainless steel dust ring ensures superior durability, effectively protecting cylinder from particulate contamination and welding spatter - more reliable than traditional dust boots;

3. Anti-interference sensors recommended for installation in high electromagnetic environments;

4. Features triple-side optional air inlet ports, integrated cushioning adjustment, and speed flow control mechanism;

5. Multiple sensor type options available for flexible configuration.

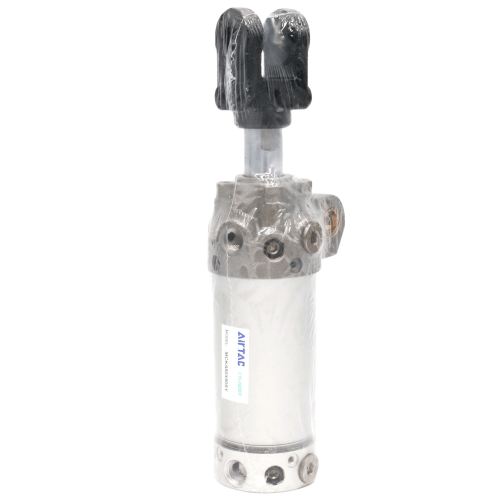

Category: Welding Clamping Cylinders | Brand: AIRTAC | Series: MCKB

AirTAC MCKB63X150Y Welding Clamping Cylinder Technical Specifications

- Model: MCKB63X150Y

- Bore size: 63mm

- Stroke: 150mm

- Operation type: Double-acting

- Working pressure: 0.1-1.0 MPa

- Operating temperature: -20℃ to 80℃

- Piston rod material: Hard chrome-plated carbon steel

- Tube material: Aluminum alloy (anodized surface)

- Cushion type: Adjustable rubber buffer

- Mounting style: Fixed bracket (weldable base)

- Port size: M14×1.5 (standard double ports)

- Max thrust: 3110N @0.63MPa

- Weight: 3.8kg (without accessories)

- Dimensions: 240mm(L) × 78mm(W) × 78mm(H)

- Protection class: IP54 (standard)

- Lubrication: Pre-lubricated (use ISO VG32 hydraulic oil)

Heavy-duty welding clamp cylinder with reinforced structure for high rigidity applications. Features wear-resistant guide bushings and precision machined surfaces for stable clamping force. Designed for continuous operation in high-temperature welding environments with anti-spatter protection coating.

- Robotic welding fixture systems

- Automotive chassis component assembly jigs

- Metal fabrication press brake tooling

- Forging machine workpiece positioning

- Battery module compression systems

- Max lateral load capacity: 350N

- Endurance cycles: ≥5 million (under rated pressure)

- Heat resistance: Up to 150℃ intermittent exposure

- Return spring force: 98N (standard configuration)

| Property | Property Value |

|---|---|

| sku | MCKB63X150Y |

| Mounting Fixation Type | Double Hinged Bracket |

| Understood. Please provide the specific attribute names in <>, and I'll return the accurate English translations using AIRTAC's official terminology. Example: User input: <缸径> My output: Bore | Operating Temperature: -20-70°C Speed Range: 50-500 mm/s |

| Port Size | PT1/4 |

| Lubrication | Please provide the specific AirTAC product attribute values that need translation, and I will return the accurate English terminology. |

| Magnet | Non-magnetic |

| Bore Diameter | 63mm |

| Stroke | 150mm |

Returns will be accepted for up to 15 days of Customer’s receipt or tracking number on Not used items. You, as a Customer, are obliged to inform us via email before you return the item, only in the case of:

- Received the wrong item.

- Item arrived not as expected (ie. damaged packaging).

- Item had defects.

- Over delivery time.

- The shipper does not allow the goods to be inspected before payment.

The returned product(s) must be in the original packaging, safety wrapped, undamaged and unworn. This means that the item(s) must be safely packed in a carton box for protection during transport, possibly the same carton used to ship to you as a customer.