2. Features multiple mounting configurations for simplified installation;

3. Supports ganged mounting of multiple cylinders, optimizing space utilization;

4. High-precision rod guidance ensures maintenance-free operation without external lubrication;

5. Available in multiple bore sizes and stroke lengths for flexible application requirements;

6. Optional high-temperature resistant seals enable reliable performance at 150°C operating conditions. (Optional)

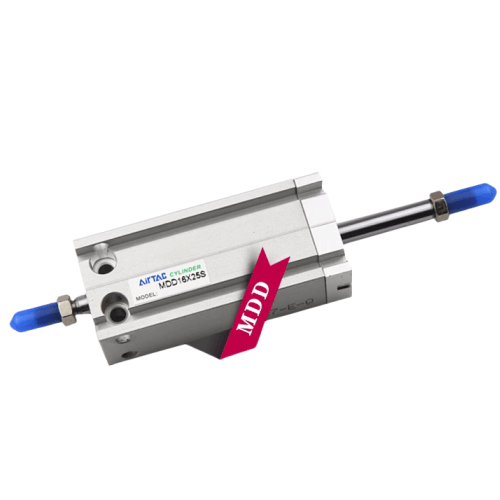

Category: Multi-Position Fixed Cylinders , Brand: AirTAC , Series: MDD

AirTAC MDD Multi-Position Dual Rod Cylinder MDD6X10S Technical Specifications

- Model Code: MDD6X10S

- Bore Size: 6mm (0.24")

- Stroke: 10mm (0.39")

- Operating Pressure: 0.05-0.9 MPa

- Buffer Type: Elastic cushion + Adjustable shock absorber

- Position Detection: Magnetic switch embeddable (M9 connector compatible)

- Mounting Style: Standard foot/base mount (ISO 15552 accessory compatible)

- Port Size: M5x0.8 (dual ports for forward/return stroke)

- Temperature Range: -20℃ to 80℃ (dry air required below 0℃)

- Cylinder Body Material: Anodized aluminum alloy (AL6063-T5)

- Rod Material: Stainless steel (SUS304) with hard chrome plating

- Seal Type: NBR rubber (optionally available in FKM for oil resistance)

- Repeat Positioning Accuracy: ±0.1mm

- Max Speed: 500mm/s (with cushioning adjustment)

- Weight: 0.65kg (including mounting hardware)

- Dimensions: 160mm(L) × 50mm(W) × 50mm(H) (stroke-included length)

Precision dual-rod pneumatic cylinder engineered for multi-point positioning tasks requiring exceptional lateral rigidity. Features synchronized dual piston rods that eliminate rotational torque, maintaining parallel movement even under eccentric loads. The through-rod design enables external position feedback mounting without stroke interference. Includes wear-compensating seals and dust-resistant wiper rings for contaminated environments.

- Automated test equipment requiring Z-axis micro-adjustments

- Semiconductor wafer handling robots

- Precision clamping fixtures with position verification

- Optical lens alignment systems

- Pharmaceutical blister packaging machines

1. Maintain 0.5-1mm clearance between rods and external guides

2. Use rod-end supports for strokes exceeding 150mm

3. Lubricate with ISO VG32 turbine oil (non-detergent)

4. For vertical mounting, install exhaust mist separator to prevent oil drain

| Property | Property Value |

|---|---|

| sku | MDD6X10S |

| Understood. Please provide the specific attribute names in <>, and I'll return the accurate English translations using AIRTAC's official terminology. Example: User input: <缸径> My output: Bore | Operating Temperature: -20°C to 70°C Speed Range: 30 to 500 mm/s |

| Port Size | M5×0.8 |

| Magnet | S-Magnetic |

| Cushion Type | Bumper Pad |

| Bore Diameter | <6mm> |

| Stroke | <10mm> |

Returns will be accepted for up to 15 days of Customer’s receipt or tracking number on Not used items. You, as a Customer, are obliged to inform us via email before you return the item, only in the case of:

- Received the wrong item.

- Item arrived not as expected (ie. damaged packaging).

- Item had defects.

- Over delivery time.

- The shipper does not allow the goods to be inspected before payment.

The returned product(s) must be in the original packaging, safety wrapped, undamaged and unworn. This means that the item(s) must be safely packed in a carton box for protection during transport, possibly the same carton used to ship to you as a customer.