2. Features profiled bidirectional piston sealing with compact dimensions and integrated oil retention structure;

3. Fixed cushioning pads on front/rear covers minimize directional switching impact;

4. Multiple rear cover configurations for enhanced installation flexibility;

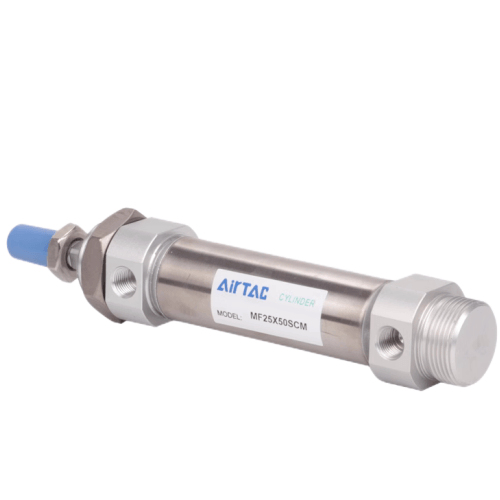

5. Crimped roller-clad bonding between stainless steel barrel and end covers ensures robust connectivity;

6. High-precision stainless steel barrel delivers superior strength and corrosion resistance;

7. Compact design: MF series achieves shorter overall length compared to ISO 6432 standard cylinders with equivalent bore/stroke;

8. Comprehensive product range with optional mounting accessories for diversified applications.

*Engineered for precision motion control in corrosive or space-constrained environments.*

AirTAC MF20X80SCM Stainless Steel Mini Cylinder Specifications

- Series: MF20~25 Stainless Steel Series

- Model: MF20X80SCM

- Bore size: 20mm

- Stroke: 80mm

- Operating pressure: 0.05–1.0 MPa

- Temperature range: -20℃ to 150℃ (continuous use)

- Port size: M5x0.8 (standard) with NPT1/8 adaptor option

- Cushioning: Adjustable rubber buffer + shock absorber

- Mounting type: Basic front flange (ISO 15552 mounting compatibility)

- Rod end: Female thread M6x1.0

- Material: SUS304 stainless steel (body/piston rod), aluminum alloy end caps

- Seal material: Fluororubber (FKM) for high temperature resistance

- Weight: 750g ±3% (without accessories)

- Dimensions:

- Total length: 144mm (at full retraction)

- Body diameter: 32mm (max cross-section)

- Mounting hole spacing: 25mm (vertical) × 18mm (horizontal)

- IP rating: IP67 (dust tight & protected against temporary immersion)

- Lubrication: Pre-lubricated (maintenance-free for 5,000km stroke under standard conditions)

- Max speed: 500mm/s (with cushioning)

- Medium: Clean dry air (ISO 8573-1:2010 Class 2-4-2)

Premium corrosion-resistant mini cylinder featuring laser-engraved position markers and anti-rotation piston rod. The electropolished SS304 construction ensures compliance with food/pharmaceutical hygiene standards. Unique 3-stage sealing system combines primary polyurethane scraper, FKM wiper, and PTFE-impregnated rod bearing for leak-free operation.

- Cleanroom automation (semiconductor/PCB manufacturing)

- Chemical processing equipment actuators

- Marine environment control systems

- High-temperature sterilization machinery

- Precision dosing pumps in food packaging

| Property | Property Value |

|---|---|

| sku | MF20X80SCM |

| Rear Cover Type | Round Type |

| Mounting Type | Without Mounting Accessories |

| Understood. Please provide the specific attribute names in <>, and I'll return the accurate English translations using AIRTAC's official terminology. Example: User input: <缸径> My output: Bore | Operating Temperature:-20-70°C Speed Range:30-800mm/s |

| Port Size | PT1/8 |

| Magnet | S-Magnetic |

| Bore Diameter | <20mm> |

| Stroke | 80 mm |

Returns will be accepted for up to 15 days of Customer’s receipt or tracking number on Not used items. You, as a Customer, are obliged to inform us via email before you return the item, only in the case of:

- Received the wrong item.

- Item arrived not as expected (ie. damaged packaging).

- Item had defects.

- Over delivery time.

- The shipper does not allow the goods to be inspected before payment.

The returned product(s) must be in the original packaging, safety wrapped, undamaged and unworn. This means that the item(s) must be safely packed in a carton box for protection during transport, possibly the same carton used to ship to you as a customer.