1. Complies with JIS (Japanese Industrial Standards) specifications;

2. Features asymmetric bidirectional sealing structure with compact dimensions and integrated oil reservoir for piston lubrication;

3. Fixed cushioning pads on both end caps minimize directional reversal impact;

4. Multiple rear cover configurations enhance mounting flexibility;

5. Riveted roller-clamped connection ensures secure and durable body connection between stainless steel barrel and end caps;

6. High-precision stainless steel tubing construction delivers exceptional strength and superior corrosion resistance;

7. Compact profile design: MF series achieves shorter overall length than ISO 6432 standard cylinders with equivalent bore size and stroke;

8. Comprehensive range of cylinder specifications and mounting accessories provides customizable solutions.

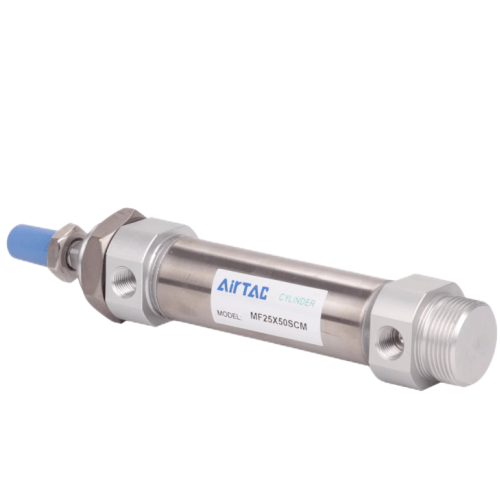

Category: Stainless Steel Mini Cylinders | Brand: AirTAC | Series: MF32~40

AirTAC MF32X275SCA Stainless Steel Miniature Cylinder Specifications

- Series: MF32~40 Compact Cylinder Family

- Model: MF32X275SCA

- Bore size: 32mm (ISO 6432 compliant)

- Stroke: 275mm ±0.5mm tolerance

- Operating pressure: 0.15–0.8 MPa (21.7–116 PSI)

- Temperature range: -20℃ to 150℃ (dry air required above 80℃)

- Port size: 1/8" NPT (G1/8 optional)

- Cushioning: Adjustable rubber bumper (both ends)

- Material:

- Tube: SUS304 stainless steel

- Piston rod: SUS420 stainless steel

- End caps: Anodized aluminum alloy

- Seals: HNBR/NBR compound (FDA compliant options available)

- Mounting type: Basic type (MF-MB) with 32mm mounting hole spacing

- Weight: 1.85kg ±3% (without accessories)

- Dimensions:

- Total length: 350mm (stroke + 75mm fixed ends)

- Body diameter: 32mm ±0.1mm

- Rod diameter: 12mm

- Mounting width: 45mm (foot bracket face)

- ISO standard: 6432/VDMA 24562

- Corrosion resistance: Passes 96hr salt spray test

High-precision stainless steel mini cylinder optimized for corrosive environments and cleanroom applications. Features laser-etched stroke markers and dual anti-rotation guides (patented design). Requires ISO 8573-1:2010 Class 3-4-3 compressed air with 40μm filtration. Lubrication: ISO VG32 turbine oil recommended for high-cycle applications.

- Semiconductor wafer handling robots

- Pharmaceutical blister packaging machines

- Marine equipment actuators

- High-temperature sterilization chambers

- Cleanroom material handling systems

1. Use M5x0.8 mounting screws with 4.4N·m torque limit

2. Maintain ≤0.5mm/m alignment tolerance

3. For vertical mounting: Add 10% stroke margin for thermal expansion

4. Maximum side load: 15N at full extension

5. Cycle rate: ≤120 CPM with cushion adjustment

| Property | Property Value |

|---|---|

| sku | MF32X275SCA |

| Rear Cover Type | Swivel Type |

| Mounting Type | Without Mounting Accessories |

| Understood. Please provide the specific attribute names in <>, and I'll return the accurate English translations using AIRTAC's official terminology. Example: User input: <缸径> My output: Bore | Operating Temperature:-20-70°C Speed Range:30-800mm/s |

| Port Size | PT1/8 |

| Magnet | S-Magnetic |

| Bore Diameter | <32 mm> |

| Stroke | 275mm |

Returns will be accepted for up to 15 days of Customer’s receipt or tracking number on Not used items. You, as a Customer, are obliged to inform us via email before you return the item, only in the case of:

- Received the wrong item.

- Item arrived not as expected (ie. damaged packaging).

- Item had defects.

- Over delivery time.

- The shipper does not allow the goods to be inspected before payment.

The returned product(s) must be in the original packaging, safety wrapped, undamaged and unworn. This means that the item(s) must be safely packed in a carton box for protection during transport, possibly the same carton used to ship to you as a customer.