2. Integrated fixed cushion rings on front/rear covers minimize impact during stroke reversal;

3. Multiple rear cover configurations enhance installation flexibility;

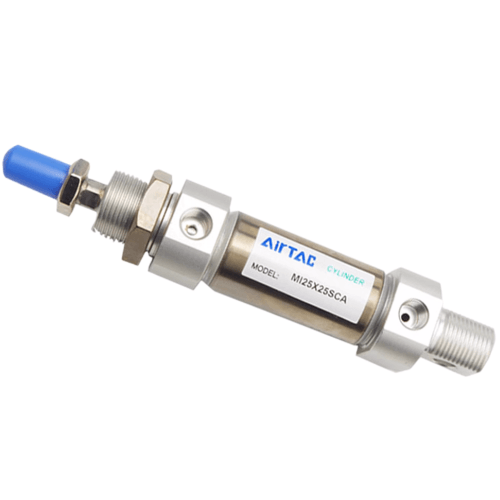

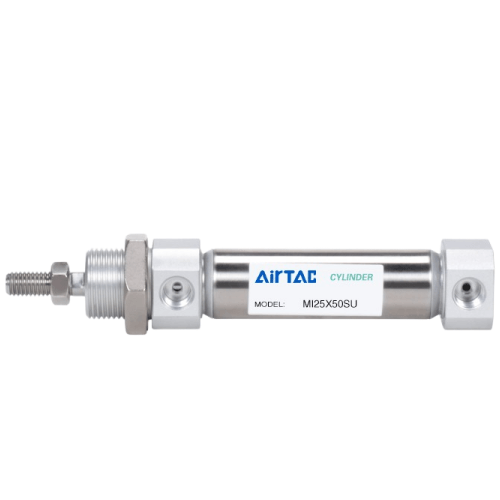

4. Crimped roller-clad structure ensures robust connection between stainless steel cylinder barrel and end covers;

5. Full stainless steel construction (piston rod & barrel) provides corrosion resistance for demanding environments;

6. Available in multiple configurations with comprehensive mounting accessories.

Category: Stainless Steel Mini Cylinders | Brand: AirTAC | Series: MI16~20

AirTAC MI16X30CA Stainless Steel Miniature Cylinder Specifications

- Series: MI16~20 (16mm bore size variant)

- Model: MI16X30CA

- Construction: Stainless steel body with chrome-plated piston rod

- Bore size: 16mm

- Stroke: 30mm (±1mm tolerance)

- Operating pressure: 0.15–0.8 MPa

- Temperature range: -20℃ to 80℃

- Cushioning: Rubber buffer + adjustable end cushion

- Port size: M5x0.8 (standard) with NPT1/8 adaptor option

- Seal material: Heat-resistant NBR (Nitrile) / Optional FKM seals

- Rod thread: M6x1 external thread (ISO 13399 compliant)

- Weight: 235g ±5g (excluding accessories)

- Dimensions:

- Total length (L): 72mm (at mid-stroke)

- Body width (W): 34mm

- Height (H): 34mm (including mounting tabs)

- ISO standard: 6432 compliant

- Mounting options: Front flange (CA-type), rear pivot, foot mounting

Corrosion-resistant miniature cylinder optimized for precision linear motion in harsh environments. Features dual cushioning system with adjustable shock absorption and hardened guide bearings for reduced lateral deflection. Requires 5μm filtered air with ISO 8573-1:2010 Class 3 air quality. Optional magnetic piston version (MI16X30CA-M) available for position sensing.

- Cleanroom automation in semiconductor manufacturing

- Pharmaceutical packaging line actuators

- Marine equipment controls (saltwater resistant)

- Food processing machinery (NSF-compliant version)

- High-cycle robotic end effectors (rated for 50 million cycles)

1. Use precision alignment jigs during mounting

2. Maintain 0.5-1mm clearance between rod end and load

3. Lubricate with ISO VG32 turbine oil (2 drops per 100km stroke)

4. For vertical mounting: Add 10% pressure compensation

| Property | Property Value |

|---|---|

| sku | MI16X30CA |

| Rear Cover Type | Swivel Type |

| Mounting Type | Without Mounting Accessories |

| Understood. Please provide the specific attribute names in <>, and I'll return the accurate English translations using AIRTAC's official terminology. Example: User input: <缸径> My output: Bore | Operating Temperature:-20-70°C Speed Range:30-800mm/s |

| Port Size | M5×0.8 |

| Magnet | Non-magnetic |

| Bore Diameter | 16mm |

| Stroke | 30mm |

Returns will be accepted for up to 15 days of Customer’s receipt or tracking number on Not used items. You, as a Customer, are obliged to inform us via email before you return the item, only in the case of:

- Received the wrong item.

- Item arrived not as expected (ie. damaged packaging).

- Item had defects.

- Over delivery time.

- The shipper does not allow the goods to be inspected before payment.

The returned product(s) must be in the original packaging, safety wrapped, undamaged and unworn. This means that the item(s) must be safely packed in a carton box for protection during transport, possibly the same carton used to ship to you as a customer.