2. Integrated fixed cushion rings on front/rear covers minimize impact during stroke reversal;

3. Multiple rear cover configurations enhance installation flexibility;

4. Crimped roller-clad structure ensures robust connection between stainless steel cylinder barrel and end covers;

5. Full stainless steel construction (piston rod & barrel) provides corrosion resistance for demanding environments;

6. Available in multiple configurations with comprehensive mounting accessories.

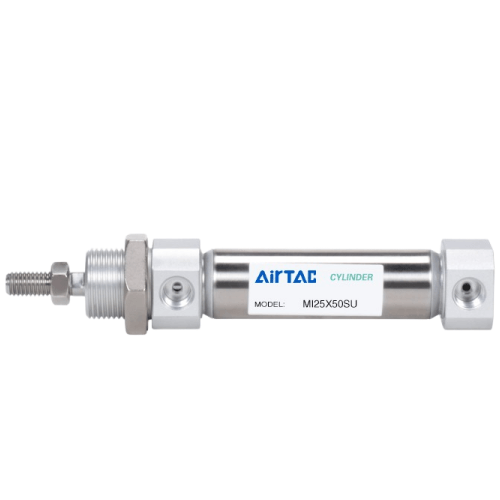

Category: Stainless Steel Mini Cylinders | Brand: AirTAC | Series: MI16~20

AirTAC MI20X270SU Stainless Steel Mini Cylinder Specifications

- Series: MI16~20 Compact Cylinder Line

- Bore size: 20mm (MI20 series)

- Stroke: 270mm

- Material: Stainless Steel (SUS304 barrel/piston rod)

- Operating pressure: 0.05–1.0 MPa

- Temperature range: -20℃ to 150℃

- Cushion type: Fixed rubber buffer + adjustable cushion (optional)

- Port size: M5x0.8 (standard), G1/8 optional

- Mounting style: Basic type (no built-in mounts), with optional accessories:

- MPA2: Front flange

- MPB4: Rear pivot

- MPC6: Side lug

- Piston rod thread: M6x1.0 (external)

- Weight: 1.25kg ±2% (without accessories)

- Dimensions:

- Body length: 270mm (stroke) + 56mm (base length)

- Overall width: 34mm

- Height (with rod): 47mm (retracted)

- Seal material: Fluororubber (FKM) standard, NBR/PU optional

- Corrosion resistance: IP67 rating (with rod cover)

- Lubrication: Pre-lubricated (Grease-free operation available)

Ultra-slim stainless steel cylinder designed for corrosive environments and precision linear motion. Features laser-etched stroke markings and dual anti-rotation guides (optional MI20X...SU-AR variant). The chrome-plated piston rod extension enhances wear resistance in high-cycle applications (500km+ service life at 0.5m/s). Compatible with vacuum applications when paired with appropriate seals.

- Food processing machinery (NSF-compliant version available)

- Medical device actuation (cleanroom compatible)

- Semiconductor wafer handling

- Pharmaceutical packaging lines

- Marine equipment controls

- Laboratory automation positioning stages

- Use 0.3Nm torque limit for mounting screws (stainless steel fasteners recommended)

- Maintain 0.5mm minimum clearance between rod end and load during alignment

- For vertical mounting: Select MI20X...SU-V model with magnetic piston

- Relubrication interval: 3 million cycles (standard) / 5 million (grease-free)

- Rod wiper replacement: Every 6 months in high-contamination environments

- Full overhaul: 10 million cycles or 3 years (whichever comes first)

| Property | Property Value |

|---|---|

| sku | MI20X270SU |

| Rear Cover Type | Radial Air Inlet |

| Mounting Type | Without Mounting Accessories |

| Understood. Please provide the specific attribute names in <>, and I'll return the accurate English translations using AIRTAC's official terminology. Example: User input: <缸径> My output: Bore | Operating Temperature:-20-70°C Speed Range:30-800mm/s |

| Port Size | PT1/8 |

| Magnet | S-Magnetic |

| Bore Diameter | <20mm> |

| Stroke | 270mm |

Returns will be accepted for up to 15 days of Customer’s receipt or tracking number on Not used items. You, as a Customer, are obliged to inform us via email before you return the item, only in the case of:

- Received the wrong item.

- Item arrived not as expected (ie. damaged packaging).

- Item had defects.

- Over delivery time.

- The shipper does not allow the goods to be inspected before payment.

The returned product(s) must be in the original packaging, safety wrapped, undamaged and unworn. This means that the item(s) must be safely packed in a carton box for protection during transport, possibly the same carton used to ship to you as a customer.