2. Integrated shock-absorbing pads on front/rear covers mitigate impact during direction changes;

3. Multiple rear cover configurations enhance installation flexibility;

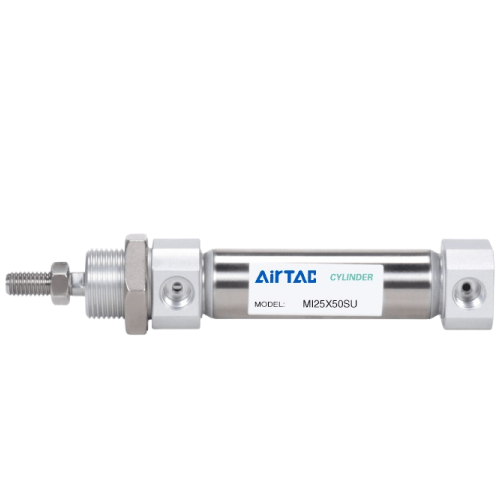

4. Crimped and rolled structure ensures robust connection between stainless steel cylinder barrel and end covers;

5. Stainless steel piston rods and cylinders provide corrosion resistance for harsh operating environments;

6. Comprehensive range of specifications and mounting accessories available for customized solutions.

Category: Stainless Steel Mini Cylinders | Brand: AIRTAC | Series: MI25~40

AirTAC MI25X125SR Stainless Steel Mini Cylinder Technical Details

- Series: MI25~40 Compact Cylinder Line

- Full Model: MI25X125SR

- Bore Size: 25 mm (±0.05mm manufacturing tolerance)

- Stroke: 125 mm (adjustable stroke version available as MI25X125SR-A)

- Material: SUS304 stainless steel body, CR12MoV piston rod

- Operating Pressure: 0.05–1.0 MPa (7-145 psi)

- Cushioning: Elastic buffer + shock absorber pad

- Mounting: Standard double-acting with front flange base (M6×1.0 mounting holes)

- Port Thread: M5×0.8 pneumatic ports (NPT1/8 optional)

- Temperature Range: -20°C to 150°C (-4°F to 302°F)

- Piston Speed: 50–700 mm/s (optimal lubrication required for max speed)

- Weight: 620 g (1.37 lbs) including mounting hardware

- Dimensions:

- Total Length: 184 mm (stroke + 59mm base length)

- Body Diameter: Ø25.5 mm

- Mounting Base: 40×40 mm square profile

- Rod End Thread: M6×1.0 male thread

- IP Rating: IP40 (dust protected)

- Lubrication: Pre-lubricated (Use ISO VG32 hydraulic oil if maintenance required)

Precision-engineered stainless steel cylinder with corrosion-resistant construction, designed for cleanroom environments and washdown applications. Features dual sealing system (NBR + PTFE) for leak prevention under vacuum conditions. Includes magnetic piston (D-M9BW sensor compatible) for position feedback.

- Pharmaceutical tablet pressing machines

- Semiconductor wafer handling robots

- Food packaging lines with steam cleaning

- Laboratory automation requiring non-magnetic properties

- Marine equipment actuators

1. Use anti-vibration washers when mounting to aluminum frames

2. Maintain 0.3-0.5mm clearance between magnetic sensor and cylinder body

3. For vertical mounting, install rod-end down to prevent fluid accumulation

4. Maximum side load: 15N at full extension (use guide mechanism if exceeded)

| Property | Property Value |

|---|---|

| sku | MI25X125SR |

| Rear Cover Type | Axial Port Type |

| Mounting Type | Without Mounting Accessories |

| Understood. Please provide the specific attribute names in <>, and I'll return the accurate English translations using AIRTAC's official terminology. Example: User input: <缸径> My output: Bore | Operating Temperature:-20-70°C Speed Range:30-800mm/s |

| Port Size | PT1/8 |

| Magnet | S-Magnetic |

| Bore Diameter | <25 mm> |

| Stroke | 125mm |

Returns will be accepted for up to 15 days of Customer’s receipt or tracking number on Not used items. You, as a Customer, are obliged to inform us via email before you return the item, only in the case of:

- Received the wrong item.

- Item arrived not as expected (ie. damaged packaging).

- Item had defects.

- Over delivery time.

- The shipper does not allow the goods to be inspected before payment.

The returned product(s) must be in the original packaging, safety wrapped, undamaged and unworn. This means that the item(s) must be safely packed in a carton box for protection during transport, possibly the same carton used to ship to you as a customer.