2. Integrated shock-absorbing pads on front/rear covers mitigate impact during direction changes;

3. Multiple rear cover configurations enhance installation flexibility;

4. Crimped and rolled structure ensures robust connection between stainless steel cylinder barrel and end covers;

5. Stainless steel piston rods and cylinders provide corrosion resistance for harsh operating environments;

6. Comprehensive range of specifications and mounting accessories available for customized solutions.

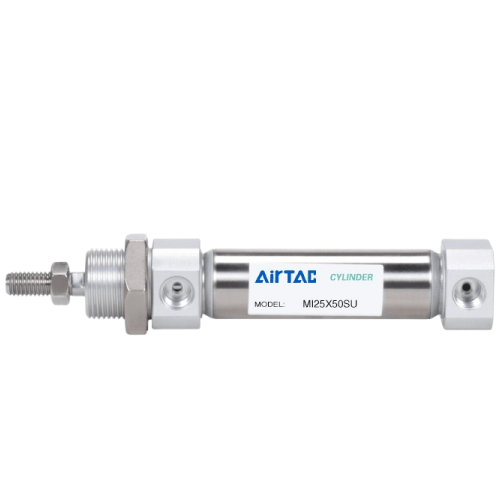

Category: Stainless Steel Mini Cylinders | Brand: AIRTAC | Series: MI25~40

AirTAC MI25X450SCATC Stainless Steel Mini Cylinder Specifications

- Model Series: MI25~40 (MI25X450SCATC belongs to MI25 series)

- Bore Size: 25 mm

- Stroke: 450 mm

- Action Type: Double-acting with auto-switch

- Material: Stainless steel body (SUS304) + CRMo alloy piston rod

- Operating Pressure: 0.05–1.0 MPa

- Cushioning: Adjustable rubber buffer (both ends)

- Temperature Range: -20°C to 80°C

- Port Size: M5x0.8 (standard) with NPT1/8 adaptor optional

- Piston Rod Thread: M10x1.25 (ISO metric fine thread)

- Mounting: Front flange with through-hole (MF25 pattern)

- Weight: 1.15 kg ±3% (including mounting hardware)

- Dimensions:

- Extended Length: 500 mm (stroke + cylinder ends)

- Body Diameter: Φ25 mm

- Mounting Flange: 40mm x 40mm square base

- Rod End Bracket: 18mm thickness

- Switch Compatibility: Supports D-M9N/D-A9N magnetic sensors

- Lubrication: Pre-lubricated (Grease-free operation available)

Corrosion-resistant mini cylinder with precision-ground rod, designed for harsh environments requiring FDA-compliant components. Features triple lip seals (NBR+PU composite) for ≤0.5mm/s low-speed stability. The MI25X450SCATC variant includes an integrated cushioning adjustment screw and IP67-rated magnetic switch slot.

- Cleanroom automation (pharmaceuticals/electronics)

- Food processing machinery actuators

- Marine equipment linear drives

- High-cycle packaging systems (up to 1,200 RPM)

- Semiconductor wafer handling robots

1. Max lateral load: ≤15N at full extension

2. Use M3x8 stainless screws for flange mounting

3. For vertical mounting: Reduce speed to ≤500 mm/s

4. Lubricate every 50km stroke distance with ISO VG32 hydraulic oil

| Property | Property Value |

|---|---|

| sku | MI25X450SCATC |

| Rear Cover Type | Swivel Type |

| Mounting Type | Center Pivot Bracket |

| Understood. Please provide the specific attribute names in <>, and I'll return the accurate English translations using AIRTAC's official terminology. Example: User input: <缸径> My output: Bore | Operating Temperature:-20-70°C Speed Range:30-800mm/s |

| Port Size | PT1/8 |

| Magnet | S-Magnetic |

| Bore Diameter | <25 mm> |

| Stroke | 450mm |

Returns will be accepted for up to 15 days of Customer’s receipt or tracking number on Not used items. You, as a Customer, are obliged to inform us via email before you return the item, only in the case of:

- Received the wrong item.

- Item arrived not as expected (ie. damaged packaging).

- Item had defects.

- Over delivery time.

- The shipper does not allow the goods to be inspected before payment.

The returned product(s) must be in the original packaging, safety wrapped, undamaged and unworn. This means that the item(s) must be safely packed in a carton box for protection during transport, possibly the same carton used to ship to you as a customer.