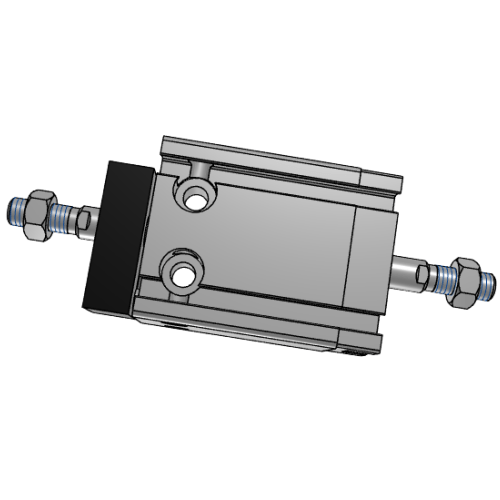

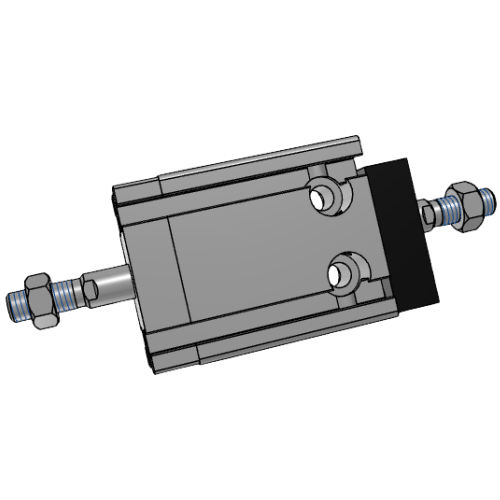

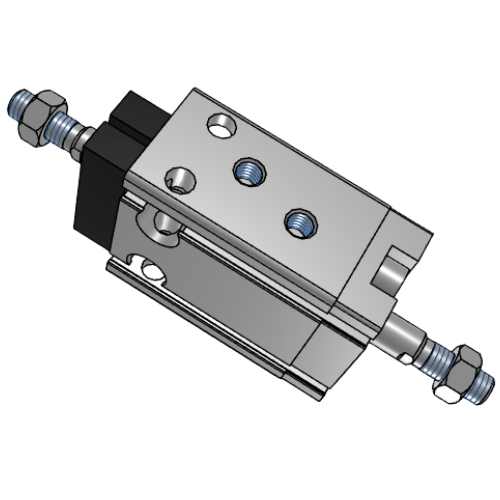

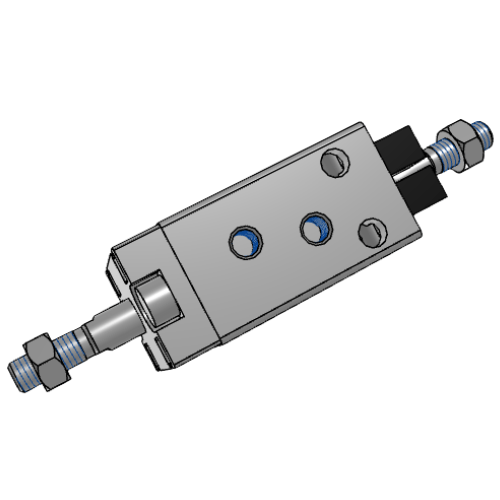

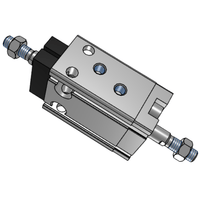

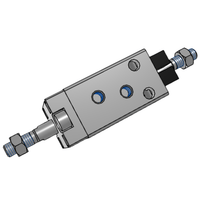

2. Body features multiple mounting configurations for simplified installation and operation;

3. Modular structure allows clustered assembly of multiple cylinders, enabling efficient space utilization;

4. Precision-guided piston rod ensures stable motion with maintenance-free operation (external lubrication not required);

5. Integrated anti-rotation locking block prevents rod rotation during operation;

6. Comprehensive specifications available for diverse application requirements;

7. Optional high-temperature seals extend operating temperature range to 150°C (0–150°C optional).

Category: Multi-position Fixed Cylinders | Brand: Airtac | Series: MKD

AirTAC MKD25X30 Multi-Position Locking Cylinder Specifications

- Model: MKD25X30

- Type: Double-acting multi-position locking cylinder

- Bore size: Ø25 mm

- Stroke: 30 mm

- Operating pressure: 0.05–1.0 MPa

- Locking positions: 3-5 programmable stops (adjustable via external clamp)

- Cushioning: Rubber buffer + adjustable air cushion

- Port size: M5×0.8 (G1/8 adaptor optional)

- Piston speed: 50-700 mm/s

- Operating temperature: -10℃ to 80℃

- Material: Aluminum alloy barrel, CRNA steel rod

- Seal type: NBR seals with wear-resistant ring

- Weight: 0.68 kg (with standard accessories)

- Dimensions: 156mm(L) × 34mm(W) × 34mm(H) (retracted state)

- ISO standard: 6432 compliant

- Protection class: IP54 (standard), IP67 optional

Precision locking cylinder with mechanical position memory function, featuring dual-position sensing grooves for magnetic switch installation. The chrome-plated piston rod integrates a dust-resistant scraper, while the multi-stage locking mechanism enables mid-stroke halting without power consumption. Requires filtered air (≤5μm) with lubrication (ISO VG32 recommended).

- PCB assembly line component positioning

- Automated welding fixture height adjustment

- Packaging machine flap control with intermediate stops

- Medical device test equipment positioning

- Automotive parts multi-stage pressing operations

| Property | Property Value |

|---|---|

| sku | MKD25X30 |

| Understood. Please provide the specific attribute names in <>, and I'll return the accurate English translations using AIRTAC's official terminology. Example: User input: <缸径> My output: Bore | Operating Temperature: -20°C to 70°C Speed Range: 30 to 500 mm/s |

| Port Size | M5×0.8 |

| Magnet | Non-magnetic |

| Cushion Type | Bumper Pad |

| Bore Diameter | <25 mm> |

| Stroke | 30mm |

Returns will be accepted for up to 15 days of Customer’s receipt or tracking number on Not used items. You, as a Customer, are obliged to inform us via email before you return the item, only in the case of:

- Received the wrong item.

- Item arrived not as expected (ie. damaged packaging).

- Item had defects.

- Over delivery time.

- The shipper does not allow the goods to be inspected before payment.

The returned product(s) must be in the original packaging, safety wrapped, undamaged and unworn. This means that the item(s) must be safely packed in a carton box for protection during transport, possibly the same carton used to ship to you as a customer.