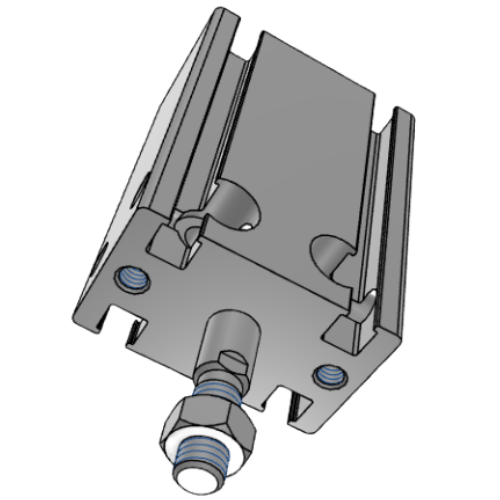

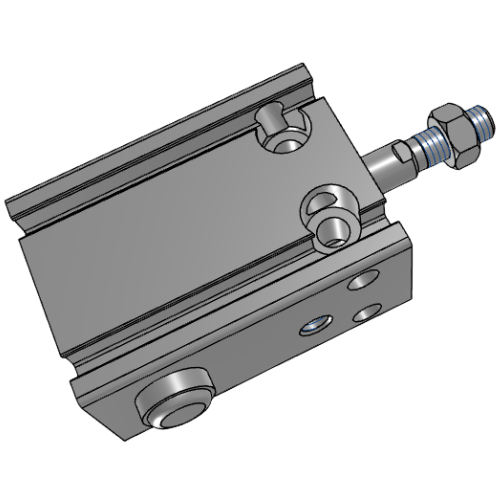

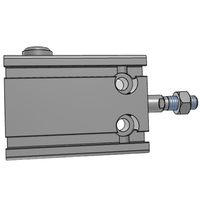

2. Multiple mounting configurations with integral body design for simplified installation;

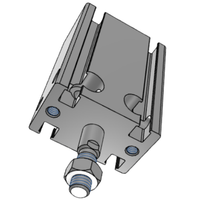

3. Modular design allows parallel cylinder arrangement, optimizing space utilization;

4. Precision-guided piston rod with self-lubricating system eliminates external lubrication requirements;

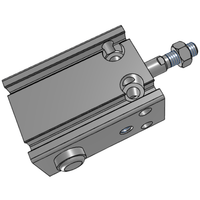

5. Comprehensive model range with standardized specifications for flexible application matching;

6. Optional high-temperature seals ensure reliable performance at 150°C operating conditions. (Optional feature)

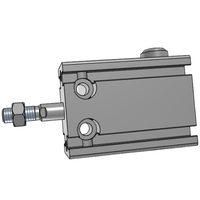

Category: Multi-position Fixed Cylinders , Brand: AirTAC , Series: MTD

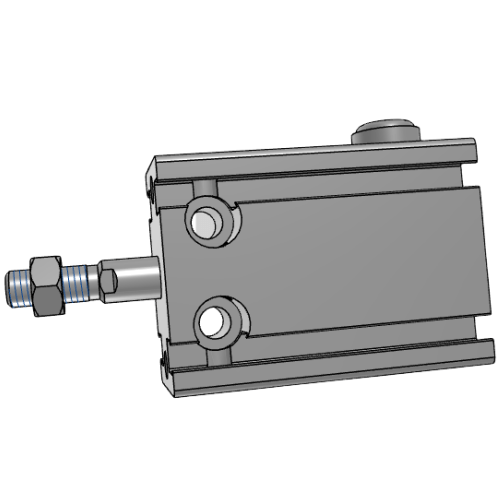

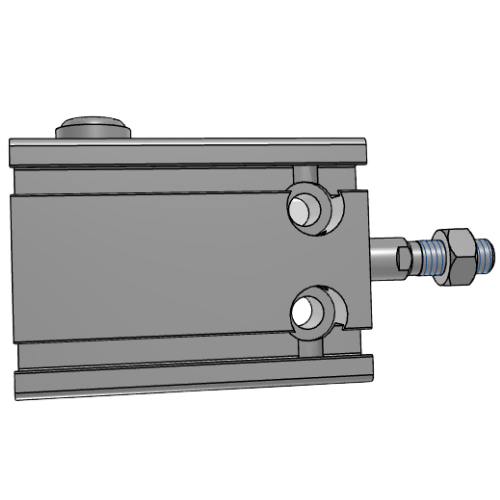

AirTAC MTD Multi-Position Locking Cylinder MTD10X5 Technical Details

- Model: MTD10X5 (Standard series with magnetic piston)

- Type: Double-acting multi-position locking cylinder

- Bore size: 10mm (0.39")

- Stroke: 5mm ±0.5mm

- Working pressure: 0.15–0.8 MPa (21.7–116 PSI)

- Locking force: 14N minimum at 0.5MPa

- Operating medium: Dry air (Lubricated air extends service life)

- Port size: M5x0.8 (Dual Rc1/8 ports optional)

- Cushioning: Adjustable rubber buffer

- Body material: Anodized aluminum alloy

- Rod material: Stainless steel (SUS304)

- Seal material: NBR (Nitrile rubber)

- Ambient temperature: -20℃ to 80℃ (-4°F to 176°F)

- Weight: 0.28kg (0.62 lbs)

- Dimensions: 53mm(L) × 25mm(W) × 25mm(H) (2.09"×0.98"×0.98")

- Mounting: 2x M3 threaded holes (30mm center distance)

- Repeat positioning accuracy: ±0.02mm

Precision locking cylinder featuring dual-position mechanical brake system with spring-assisted emergency stop function. The MTD10X5's chromium-plated piston rod and wear-resistant guide rings ensure ≤0.01mm/100mm straightness deviation. Integrated magnetic piston enables position feedback when paired with reed sensors (Optional sensor kit: D-A93). Requires 5μm filtered air with ISO 8573-1:2010 Class 3.2.3 air quality.

- PCB component insertion machines (position retention during soldering)

- Automotive fuel injector testing fixtures

- Pharmaceutical blister packaging alignment systems

- 3D printer bed stabilization mechanisms

- Microscope stage positioning in semiconductor inspection

| Property | Property Value |

|---|---|

| sku | MTD10X5 |

| Understood. Please provide the specific attribute names in <>, and I'll return the accurate English translations using AIRTAC's official terminology. Example: User input: <缸径> My output: Bore | Operating Temperature: -20-70°C Speed Range: 50-500 mm/s |

| Port Size | M5×0.8 |

| Magnet | Non-magnetic |

| Cushion Type | Bumper Pad |

| Bore Diameter | <10mm> |

| Stroke | <5mm> |

Returns will be accepted for up to 15 days of Customer’s receipt or tracking number on Not used items. You, as a Customer, are obliged to inform us via email before you return the item, only in the case of:

- Received the wrong item.

- Item arrived not as expected (ie. damaged packaging).

- Item had defects.

- Over delivery time.

- The shipper does not allow the goods to be inspected before payment.

The returned product(s) must be in the original packaging, safety wrapped, undamaged and unworn. This means that the item(s) must be safely packed in a carton box for protection during transport, possibly the same carton used to ship to you as a customer.