2、Cylinder barrels undergo precision surface treatments to significantly enhance wear resistance and corrosion durability;

3、Integrated spindle air purge functionality for enhanced machining cleanliness.

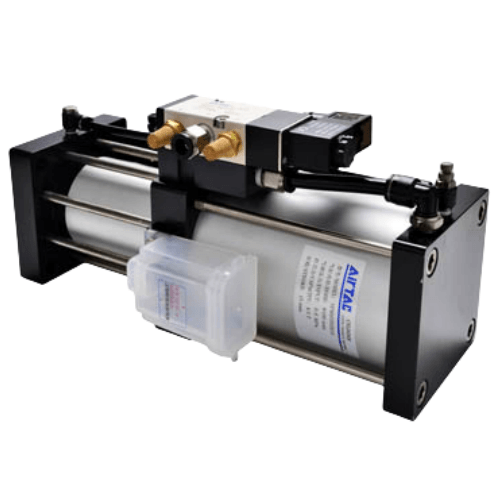

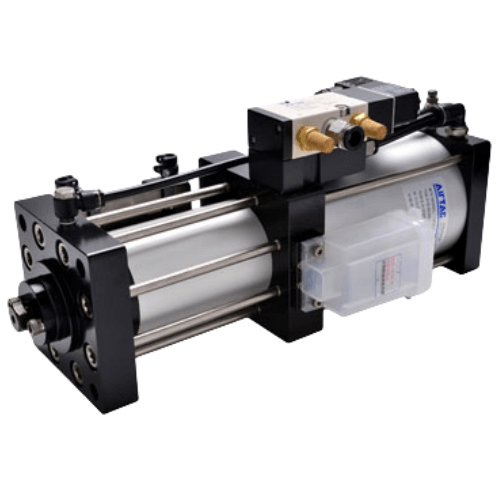

Category: Tool Clamping Cylinders | Brand: AirTAC | Series: NPM

AirTAC NPM60T70X15CIL Knife Edge Cylinder Technical Details

- Model: NPM60T70X15CIL

- Type: Double-acting ISO standard knife edge cylinder

- Bore size: 60mm (ISO 6432 compliant)

- Stroke: 70mm (adjustable cushioning)

- Operating pressure: 0.05–1.0 MPa

- Temperature range: -20℃ to 80℃

- Port size: G1/8 (NPT1/8 optional)

- Cushioning type: Fixed buffer + adjustable elastic stopper

- Mounting type: C-face (ISO 15552 flange pattern)

- Rod material: Hard chrome-plated steel (5μm coating)

- Tube material: Anodized aluminum alloy

- Piston rod diameter: 20mm

- Number of pistons: Dual-axis structure

- Repeat positioning accuracy: ±0.1mm

- Max speed: 500mm/s (with cushioning engaged)

- Weight: 3.2kg (without accessories)

- Dimensions: 215mm(L) × 80mm(W) × 80mm(H)

High-precision dual-axis cylinder featuring hardened knife-edge piston design for minimal deflection during high moment load operations. Incorporates multi-stage buffering system with shock absorption pads for smooth end-of-stroke deceleration. Sealed with HNBR wipers and NBU-PTFE composite seals for 2,000km maintenance-free operation.

- Automatic tool changers in CNC machining centers

- Precision clamping in optical lens polishing systems

- High-speed sorting mechanisms for electronic components

- Palletizing robot end-effector positioning

- Semiconductor wafer handling vacuum chambers

| Property | Property Value |

|---|---|

| sku | NPM60T70X15CIL |

| Output Force | Output Force 6.0 Tons |

| Micro Switch | 2 Micro Switches |

| Blade Stroke | <15mm> |

| Port Size | PT3/8 |

| Standard Voltage | AC 110V |

| Hydraulic Cylinder Bore | 70mm |

Returns will be accepted for up to 15 days of Customer’s receipt or tracking number on Not used items. You, as a Customer, are obliged to inform us via email before you return the item, only in the case of:

- Received the wrong item.

- Item arrived not as expected (ie. damaged packaging).

- Item had defects.

- Over delivery time.

- The shipper does not allow the goods to be inspected before payment.

The returned product(s) must be in the original packaging, safety wrapped, undamaged and unworn. This means that the item(s) must be safely packed in a carton box for protection during transport, possibly the same carton used to ship to you as a customer.