2、Features centralized intake/exhaust ports and unified wiring layout to streamline troubleshooting processes and enhance maintenance efficiency;

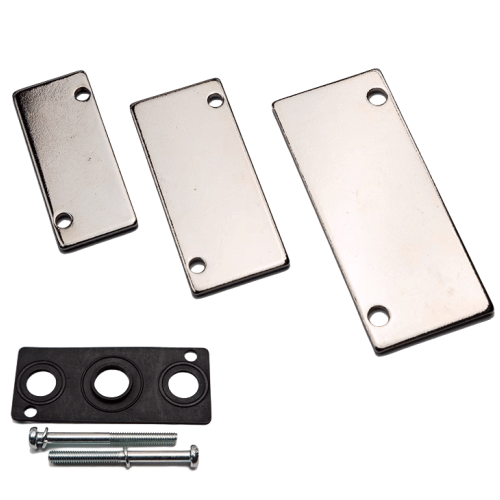

3、Modular design with exceptional flexibility and scalability, allowing arbitrary combination or expansion of connected directional control valves according to operational requirements;

Category: Cover Plates , Brand: Airtac , Series: P-3V-M

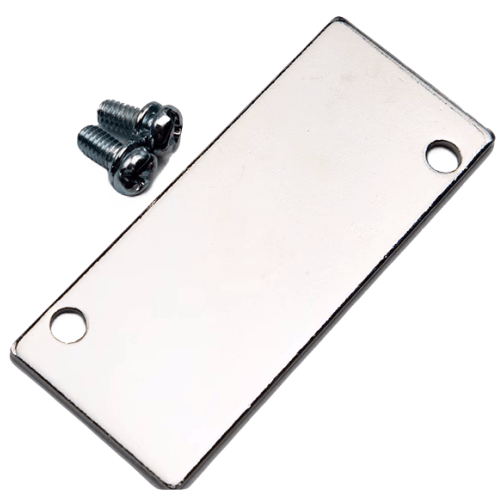

AirTAC P-3V-M Cover Plate P-3V200M-R1 Technical Details

- Model: P-3V200M-R1

- Type: Aluminum alloy valve cover plate

- Mounting hole spacing: 200mm (±0.2mm tolerance)

- Compatible valve body: P-3V200 series

- Material: 6063-T5 aluminum alloy

- Surface treatment: Anodized (gray, MIL-A-8625 standard)

- Seal material: Oil-resistant NBR rubber (Shore A 70±5)

- Temperature resistance: -30℃ to 150℃ (static), -10℃ to 80℃ (operating)

- Protection rating: IP54 (with proper valve assembly)

- Fastener specification: M6×12 stainless steel screws (4 pcs included)

- Weight: 480g ±2% (including seals and fasteners)

- Dimensions: 220mm(L) × 45mm(W) × 15mm(H)

Heavy-duty interface component designed for modular pneumatic systems, featuring precision-machined mounting surfaces and chemical-resistant coating. The reinforced rib structure enhances stability during high-frequency valve switching (up to 5Hz). Includes pre-installed vibration-resistant washers and alignment pins for maintenance-free operation.

- Multi-valve manifold assemblies in packaging machinery

- Centralized control systems for automotive production lines

- Plastic injection molding machine pneumatic clusters

- High-cycle textile equipment manifolds

- Laboratory pneumatic test benches

| Property | Property Value |

|---|---|

| sku | P-3V200M-R1 |

Returns will be accepted for up to 15 days of Customer’s receipt or tracking number on Not used items. You, as a Customer, are obliged to inform us via email before you return the item, only in the case of:

- Received the wrong item.

- Item arrived not as expected (ie. damaged packaging).

- Item had defects.

- Over delivery time.

- The shipper does not allow the goods to be inspected before payment.

The returned product(s) must be in the original packaging, safety wrapped, undamaged and unworn. This means that the item(s) must be safely packed in a carton box for protection during transport, possibly the same carton used to ship to you as a customer.