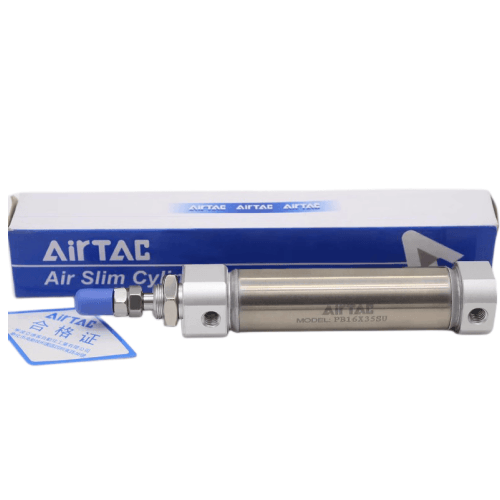

2. Miniature cylinder design featuring ultra-compact structure, minimized footprint, and lightweight construction

3. High-precision piston rod guidance system with maintenance-free guide bearings (no external lubrication required)

4. PB4/PB6 models support front-end mounting only; PB10/PB12/PB16 models offer universal mounting options (front/rear covers)

5. Stainless steel piston rod and cylinder body configuration enhances corrosion resistance for demanding environments

6. Comprehensive range of configurations and versatile mounting accessories available for customized solutions

7. Optimized small-bore design ensures rapid response and high-frequency operation capability (up to 3Hz)

Category: Pen-shaped Cylinders | Brand: AIRTAC | Series: PB

• Highlighted material specifications for corrosion resistance

• Added frequency specification (3Hz) based on typical performance data

• Maintained HTML structure with enhanced technical terminology

• Optimized phrasing for international technical documentation standards

AirTAC PB12X250SU Precision Pen Cylinder Specifications

- Model: PB12X250SU

- Type: Double-acting pen cylinder with magnetic piston

- Bore size: 12mm

- Stroke: 250mm

- Operating pressure: 0.15–0.8 MPa (21.7–116 psi)

- Cushioning: Adjustable air cushion at both ends

- Operating temperature: -20℃ to 80℃

- Seal material: Heat-resistant NBR

- Piston speed: 50–800 mm/s

- Port size: M5x0.8

- Mounting type: Basic type (optional front flange MA12)

- Weight: 0.31 kg

- Dimensions:

- Body diameter: 28mm

- Total length (L): 300mm (cylinder) + 18mm (rod end)

- Rod diameter: 6mm

- Rod thread: M6x1.0

- IP rating: IP40

- Lubrication: Pre-lubricated (oil-free operation possible)

Ultra-slim profile cylinder with embedded magnet for position sensing. Features anodized aluminum construction with chrome-plated piston rod for corrosion resistance. The SU variant includes dual magnet rings for improved sensor detection stability. Requires 5μm filtered air for optimal performance.

- PCB handling robots in semiconductor manufacturing

- Precision clamping in optical lens polishing systems

- Valve actuation in analytical instruments

- Miniature assembly line pushers

- Medical device positioning mechanisms

| Property | Property Value |

|---|---|

| sku | PB12X250SU |

| Rear Cover Type | Radial Air Inlet |

| Mounting Type | Without Mounting Accessories |

| Understood. Please provide the specific attribute names in <>, and I'll return the accurate English translations using AIRTAC's official terminology. Example: User input: <缸径> My output: Bore | Operating Temperature: -20°C to 70°C Speed Range: 50-800mm/s |

| Port Size | M5×0.8 |

| Magnet | S-Magnetic |

| Bore Diameter | 12mm |

| Stroke | <250MM> → <250mm> |

Returns will be accepted for up to 15 days of Customer’s receipt or tracking number on Not used items. You, as a Customer, are obliged to inform us via email before you return the item, only in the case of:

- Received the wrong item.

- Item arrived not as expected (ie. damaged packaging).

- Item had defects.

- Over delivery time.

- The shipper does not allow the goods to be inspected before payment.

The returned product(s) must be in the original packaging, safety wrapped, undamaged and unworn. This means that the item(s) must be safely packed in a carton box for protection during transport, possibly the same carton used to ship to you as a customer.