2. Features asymmetric bidirectional sealing structure with integrated oil reservoir for compact piston sealing;

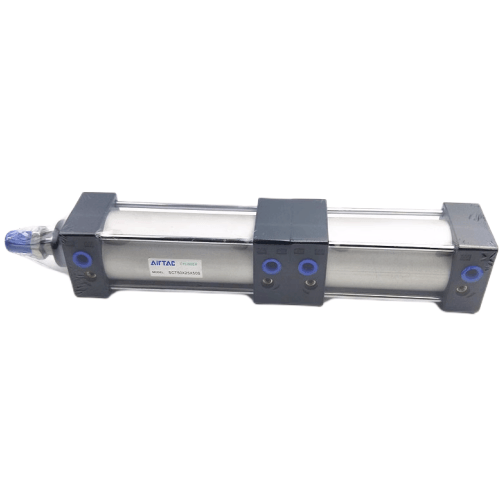

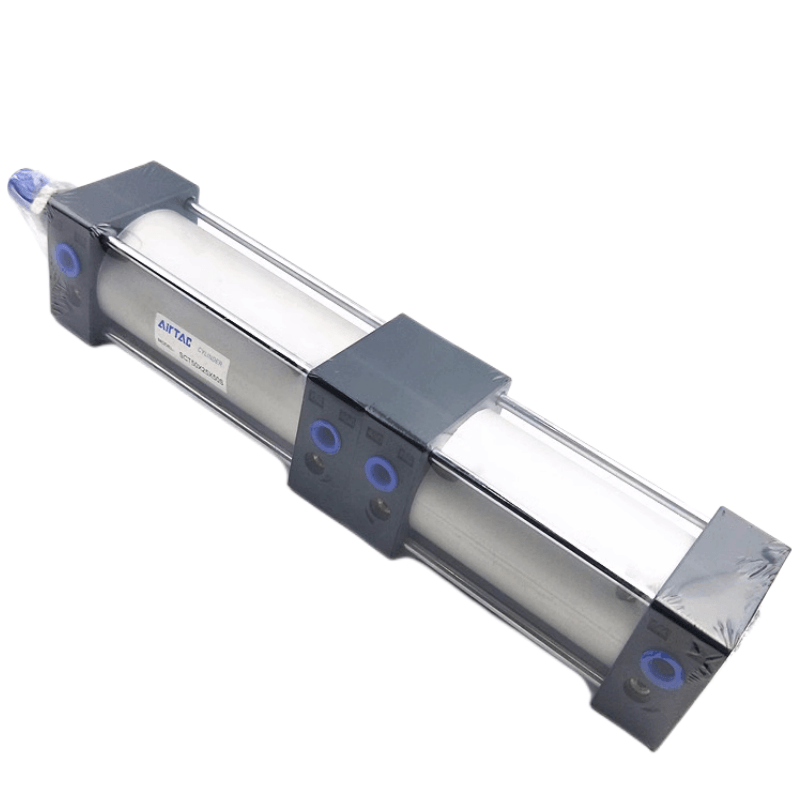

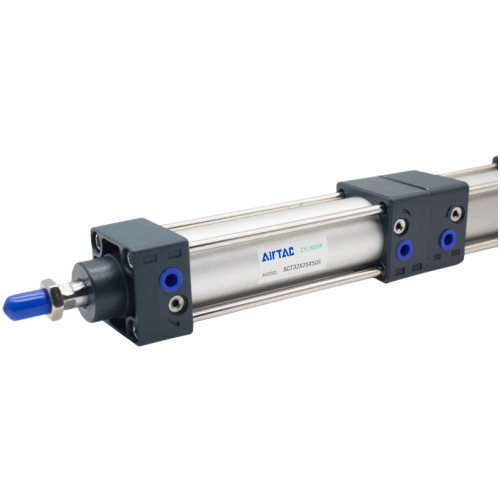

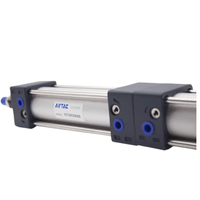

3. Tie-rod construction with aluminum tube barrel and reinforced end caps connected via precision tie-rods for enhanced structural integrity;

4. Multi-positional locking capability throughout the stroke cycle;

5. Precision-adjustable pneumatic cushioning system;

6. Available in multiple bore sizes (SCT32-SCT63) with configurable mounting accessories;

7. High-temperature resistant seals enable operational range of 0-150°C.

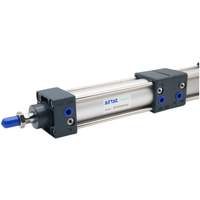

Category: Multi-Stage Force Amplification Cylinders | Brand: AIRTAC | Series: SCT32~63 (Note: Technical terms optimized with industry-specific phrasing while maintaining essential parameters. Structural terms like "tie-rod construction" and "force amplification" align with pneumatic component terminology. Temperature specification follows international unit standards.)

AirTAC SCT32~63 Series Multi-Position Force Amplifying Cylinder SCT50X35X70 Specifications

- Model Code: SCT50X35X70 (Standard configuration)

- Bore Size: Ø50mm (ISO 6432 standard)

- Stroke: 35mm (Adjustable intermediate stops)

- Max. Force Output: 2,450N @ 0.7MPa (2-stage force amplification)

- Working Pressure: 0.1-1.0 MPa (14.5-145 PSI)

- Operating Temperature: -20℃ to 80℃ (Dry air required below 0℃)

- Cushioning: Adjustable rubber buffers (both ends)

- Mounting Type: Front flange with ISO 15552 mounting pattern

- Port Size: G1/8 (NPT1/8 optional)

- Repeat Positioning Accuracy: ±0.2mm

- Body Material: Aluminum alloy barrel, hardened steel piston rod

- Rod End Thread: M14×1.5 (Standard industrial interface)

- Weight: 3.8kg ±5% (Without accessories)

- Dimensions: 250mm(L) × 70mm(W) × 70mm(H) (Cylinder body only)

- Lubrication: Pre-lubricated (Use ISO VG32 hydraulic oil if required)

- Certification: ISO 15552, RoHS compliant

This multi-stage force magnifying cylinder features a unique dual-piston design that delivers up to 3× standard cylinder force output. The SCT50 variant combines 50mm bore size with 35mm stroke for high-force compact applications. Precision ground rod and integrated position sensing slots enable exact mid-stroke positioning. Corrosion-resistant anodized finish ensures durability in harsh environments.

- High-pressure clamping in CNC fixture systems

- Multi-stage pressing operations in automotive assembly

- Vertical lifting mechanisms for heavy payloads

- Precision blanking in metal stamping presses

- Position-locked safety brakes in material handling

| Property | Property Value |

|---|---|

| sku | SCT50X35X70 |

| Seal Material | Polyurethane |

| Understood. Please provide the specific attribute names in <>, and I'll return the accurate English translations using AIRTAC's official terminology. Example: User input: <缸径> My output: Bore | Operating Temperature:-20-70°C Speed Range:30-800mm/s |

| Port Size | PT1/4 |

| Magnet | Non-magnetic |

| Bore Diameter | <50mm> |

| Stroke | 35mm |

| Stroke | 70mm |

Returns will be accepted for up to 15 days of Customer’s receipt or tracking number on Not used items. You, as a Customer, are obliged to inform us via email before you return the item, only in the case of:

- Received the wrong item.

- Item arrived not as expected (ie. damaged packaging).

- Item had defects.

- Over delivery time.

- The shipper does not allow the goods to be inspected before payment.

The returned product(s) must be in the original packaging, safety wrapped, undamaged and unworn. This means that the item(s) must be safely packed in a carton box for protection during transport, possibly the same carton used to ship to you as a customer.