2、Piston sealing features a custom-shaped bidirectional sealing structure with compact dimensions and integrated oil reservoir function;

3、Square extruded aluminum tubing construction without tie rods, enhanced by corrosion-resistant anodized finish;

4、Smooth and precise cushioning adjustment mechanism;

5、Comprehensive range of cylinder sizes and mounting accessories for flexible system integration;

6、High-temperature resistant sealing materials enable operation in 0~150°C environments.

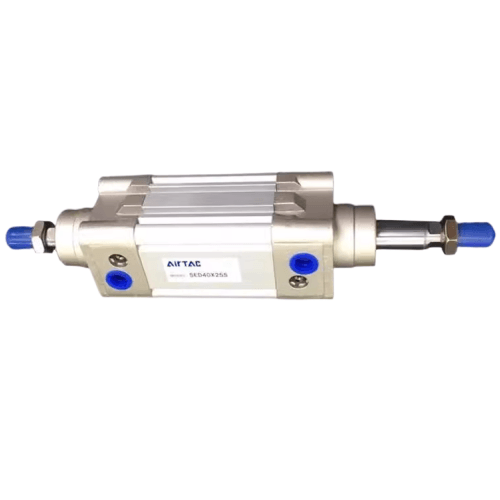

Category: Double-Axis Cylinders, Brand: AirTAC, Series: SED Series

AirTAC SED Series Double Rod Cylinder SED100X105 Technical Details

- Model: SED100X105

- Type: ISO 6432 standard double rod pneumatic cylinder

- Bore size: Ø100 mm

- Stroke: 105 mm (customizable 25-500 mm)

- Working pressure: 0.05-1.0 MPa

- Cushioning: Adjustable pneumatic cushion (both ends)

- Operating temperature: -20℃ to 80℃

- Port size: G3/8 (NPT1/2 optional)

- Mounting: Basic series (MF1) / Foot-mounted (MP2) / Flange-mounted (MF3)

- Rod material: Hard chrome-plated steel rod

- Tube material: Aluminum alloy with oxidation treatment

- Seal type: NBR seals standard (PU/Viton available)

- Weight: 6.8 kg (bare cylinder) / 7.2 kg (with standard accessories)

- Dimensions: 526mm(L) × 122mm(W) × 122mm(H) (at mid-stroke position)

- Rod diameter: Ø25mm (both rods)

- Max thrust: 785N @ 0.7MPa

- ISO speed range: 50-750 mm/s

- Protection class: IP54 (standard) / IP67 (optional wiper upgrade)

Industrial-grade double rod cylinder featuring symmetrical force output and position stability. The through-rod design eliminates differential pressure areas, making it ideal for precision alignment tasks. Features integrated mounting grooves and corrosion-resistant construction for harsh environments. Requires filtered air with 5-50μm particles and ISO VG32 lubricator oil (optional auto-lube).

- Precision press-fit operations in automotive assembly

- Bidirectional clamping fixtures for CNC machining centers

- Material handling systems requiring equal force both directions

- Plastic injection molding ejector mechanisms

- Glass tempering line conveyor positioning

| Property | Property Value |

|---|---|

| sku | SED100X105 |

| Seal Material | Polyurethane |

| Understood. Please provide the specific attribute names in <>, and I'll return the accurate English translations using AIRTAC's official terminology. Example: User input: <缸径> My output: Bore | Operating Temperature:-20-70°C Speed Range:30-800mm/s |

| Port Size | PT 1/2 |

| Piston Rod Material | Medium Carbon Steel |

| Magnet | Non-magnetic |

| Bore Diameter | 100mm |

| Stroke | 105mm |

Returns will be accepted for up to 15 days of Customer’s receipt or tracking number on Not used items. You, as a Customer, are obliged to inform us via email before you return the item, only in the case of:

- Received the wrong item.

- Item arrived not as expected (ie. damaged packaging).

- Item had defects.

- Over delivery time.

- The shipper does not allow the goods to be inspected before payment.

The returned product(s) must be in the original packaging, safety wrapped, undamaged and unworn. This means that the item(s) must be safely packed in a carton box for protection during transport, possibly the same carton used to ship to you as a customer.