2、Piston sealing features a custom-shaped bidirectional sealing structure with compact dimensions and integrated oil reservoir function;

3、Square extruded aluminum tubing construction without tie rods, enhanced by corrosion-resistant anodized finish;

4、Smooth and precise cushioning adjustment mechanism;

5、Comprehensive range of cylinder sizes and mounting accessories for flexible system integration;

6、High-temperature resistant sealing materials enable operation in 0~150°C environments.

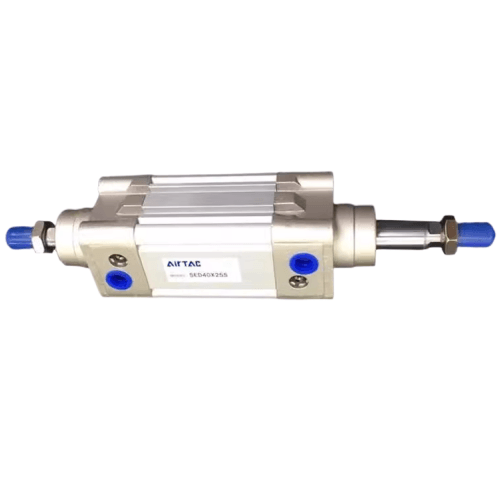

Category: Double-Axis Cylinders, Brand: AirTAC, Series: SED Series

AirTAC SED63X160S Double Rod Cylinder Specifications

- Model: SED63X160S

- Type: Double rod pneumatic cylinder (ISO 6432 standard)

- Bore size: 63 mm

- Stroke: 160 mm

- Operating pressure: 0.1–1.0 MPa

- Operating temperature: -20℃ to 80℃

- Cushion type: Adjustable pneumatic cushion (both ends)

- Mounting style: Front flange mounting (ISO 15552 compliant)

- Port size: G1/4 (NPT1/4 optional)

- Piston rod thread: M16×1.5 (double-ended)

- Material: Aluminum alloy barrel, chrome-plated steel rod

- Seal material: NBR (nitrile rubber)

- Weight: Approximately 3.5 kg (without accessories)

- Dimensions: 320mm(L) × 76mm(W) × 76mm(H) (stroke included)

- Rod stroke tolerance: ±1.5mm

- Maximum theoretical force: 3120N at 1.0 MPa

- Lubrication: Pre-lubricated (Oil-free operation possible)

A high-rigidity dual piston rod cylinder designed for applications requiring precise linear motion and moment load resistance. The symmetrical double-rod structure provides balanced thrust force and enhanced stability during reciprocating movements. Features corrosion-resistant construction with anodized aluminum body and multi-lip sealing system for leak-proof operation.

- Precision positioning in automated assembly lines

- Material handling systems requiring dual-side force transmission

- Packaging machinery with simultaneous front/rear tooling actuation

- CNC machine tool clamping mechanisms

- Automated welding equipment positioners

- Allow 0.5-1mm clearance for thermal expansion during mounting

- Use 40μm filtered air with ISO 8573-1:2010 Class 4.4.2 standards

- For vertical installations, implement anti-rotation mechanism

- Lubricate via air line lubricator (ISO VG32 recommended) if using oil mist

- Max lateral load: 180N at piston rod end

| Property | Property Value |

|---|---|

| sku | SED63X160S |

| Seal Material | Polyurethane |

| Understood. Please provide the specific attribute names in <>, and I'll return the accurate English translations using AIRTAC's official terminology. Example: User input: <缸径> My output: Bore | Operating Temperature:-20-70°C Speed Range:30-800mm/s |

| Port Size | PT3/8 |

| Piston Rod Material | Medium Carbon Steel |

| Magnet | S-Magnetic |

| Bore Diameter | 63mm |

| Stroke | 160mm |

Returns will be accepted for up to 15 days of Customer’s receipt or tracking number on Not used items. You, as a Customer, are obliged to inform us via email before you return the item, only in the case of:

- Received the wrong item.

- Item arrived not as expected (ie. damaged packaging).

- Item had defects.

- Over delivery time.

- The shipper does not allow the goods to be inspected before payment.

The returned product(s) must be in the original packaging, safety wrapped, undamaged and unworn. This means that the item(s) must be safely packed in a carton box for protection during transport, possibly the same carton used to ship to you as a customer.