2、Piston sealing features a custom-shaped bidirectional sealing structure with compact dimensions and integrated oil reservoir function;

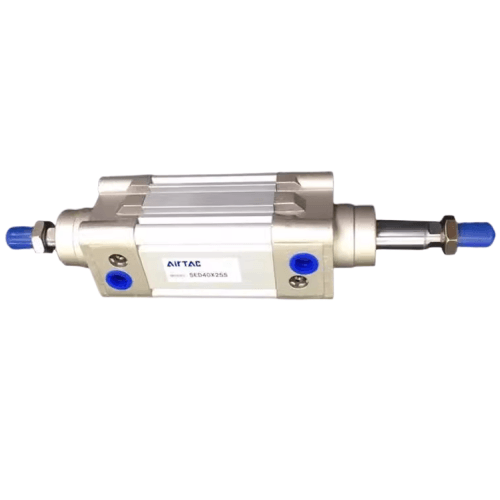

3、Square extruded aluminum tubing construction without tie rods, enhanced by corrosion-resistant anodized finish;

4、Smooth and precise cushioning adjustment mechanism;

5、Comprehensive range of cylinder sizes and mounting accessories for flexible system integration;

6、High-temperature resistant sealing materials enable operation in 0~150°C environments.

Category: Double-Axis Cylinders, Brand: AirTAC, Series: SED Series

AirTAC SED Series Double Rod Cylinder SED80X60S Technical Specifications

- Model: SED80X60S

- Type: ISO 6432 compliant double rod pneumatic cylinder

- Bore size: 80mm (3.15")

- Stroke: 60mm (2.36") [Customizable up to 500mm]

- Operating pressure: 0.05-1.0 MPa (7-145 psi)

- Temperature range: -20℃ to 80℃ (-4°F to 176°F)

- Cushion type: Adjustable air cushion at both ends

- Mounting style: Basic type (MF1), front flange (MF2), rear flange (MF3), or foot mounting (MF4)

- Port size: G1/4 (BSPP) or 1/4" NPT optional

- Rod material: Hard chrome-plated steel (SUS304 optional)

- Tube material: Anodized aluminum alloy (6063-T5)

- Seal material: Heat-resistant NBR + Polyurethane (PU) combination

- Piston speed: 50-800 mm/s (with cushioning)

- Weight: 3.8kg (8.38 lbs) ±2%

- Dimensions:

- Body length: 191mm (7.52")

- Overall width: 112mm (4.41")

- Height with rods: 94mm (3.70")

- Rod diameter: 20mm (0.79") per rod

- ISO standard cleanliness: Class 4 (Requires 40μm filtration)

High-precision double rod cylinder featuring symmetrical force transmission and enhanced lateral load capacity. The dual-piston rod design minimizes rotational deflection during operation, achieving ≤0.1mm lateral deviation at full stroke. Incorporates wear-compensating seals and multi-stage buffering system for smooth deceleration.

- Precision alignment systems in semiconductor manufacturing

- Vertical lifting mechanisms for CNC tool changers

- Simultaneous clamping devices in injection molding machines

- Positioning stages for optical inspection equipment

- Parallel gripper actuation in robotic workcells

- Standard: 5,000km (3,107mi) travel distance @ 0.5MPa

- Extended: 8,000km (4,971mi) with AirTAC Super Lubricant (ASL-32)

| Property | Property Value |

|---|---|

| sku | SED80X60S |

| Seal Material | Polyurethane |

| Understood. Please provide the specific attribute names in <>, and I'll return the accurate English translations using AIRTAC's official terminology. Example: User input: <缸径> My output: Bore | Operating Temperature:-20-70°C Speed Range:30-800mm/s |

| Port Size | PT3/8 |

| Piston Rod Material | Medium Carbon Steel |

| Magnet | S-Magnetic |

| Bore Diameter | 80 mm |

| Stroke | 60mm |

Returns will be accepted for up to 15 days of Customer’s receipt or tracking number on Not used items. You, as a Customer, are obliged to inform us via email before you return the item, only in the case of:

- Received the wrong item.

- Item arrived not as expected (ie. damaged packaging).

- Item had defects.

- Over delivery time.

- The shipper does not allow the goods to be inspected before payment.

The returned product(s) must be in the original packaging, safety wrapped, undamaged and unworn. This means that the item(s) must be safely packed in a carton box for protection during transport, possibly the same carton used to ship to you as a customer.