1. Complies with enterprise standards;

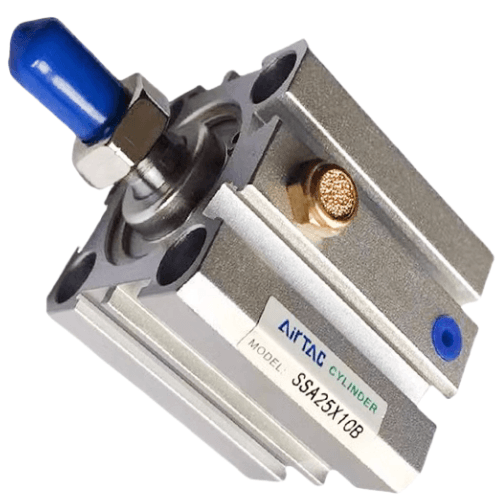

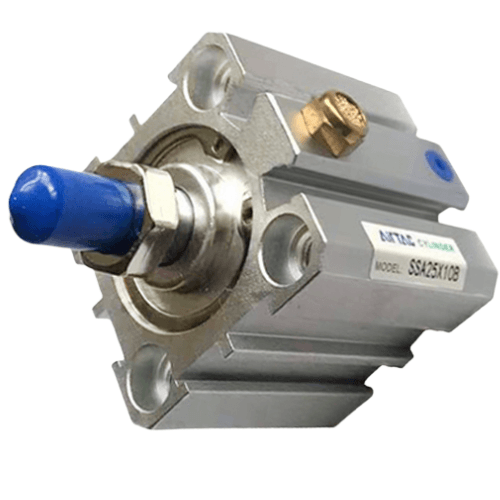

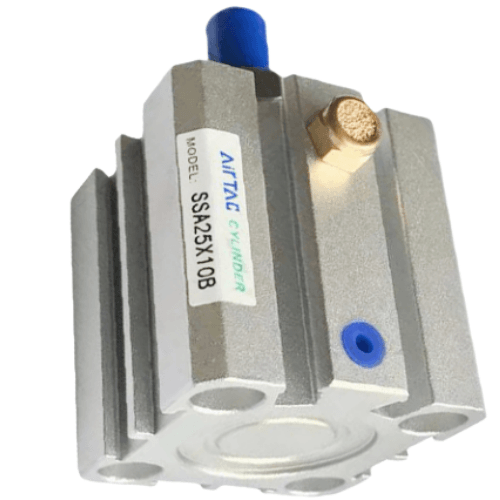

2. Features riveted structure between cylinder body/rear cover and piston/piston rod for compact reliability;

3. Hard-anodized inner bore surface after roller burnishing ensures superior wear resistance and durability;

4. Custom-engineered bidirectional piston sealing with integrated oil reservoir in space-saving design;

5. Ultra-compact profile optimizes installation space utilization;

6. Perimeter sensor grooves enable simplified sensor mounting;

7. Multiple specifications available with configurable cylinder options.

Category: Compact Cylinders | Brand: AIRTAC | Series: SSA

AirTAC SSA Series Single-Action Compact Cylinder SSA20X15B Specifications

- Model: SSA20X15B

- Type: Single-Action (Spring Return) Compact Cylinder

- Bore Size: 20mm

- Stroke: 15mm (±1mm tolerance)

- Operating Pressure: 0.15–0.8 MPa (21.7–116 psi)

- Operating Temperature: -20℃ to 80℃ (-4°F to 176°F)

- Port Size: M5x0.8 (Standard) or NPT1/8 (Optional)

- Cushioning: Adjustable Rubber Buffer

- Mounting Style: Basic Type (No built-in mounting)

- Cylinder Material: Aluminum Alloy (Hard Anodized)

- Piston Rod Material: Stainless Steel (SUS304)

- Seal Material: NBR (Nitrile Rubber)

- Weight: 0.25kg (0.55 lbs)

- Dimensions (L×W×H):

76mm (Extended Length) × 32mm (Body Width) × 32mm (Body Height)

Collapsed Length: 61mm - ISO Standard: 6432 (25mm profile series)

- Protection Rating: IP54 (Standard sealing)

- Lubrication: Pre-lubricated (Oil-free operation possible)

The SSA20X15B ultra-slim cylinder combines high rigidity with 25% reduced height compared to standard models, featuring a unique square-body design for space optimization. Its anti-rotation guide structure ensures precise linear motion, while the double-sealed piston design achieves ≤0.5mm/s leakage rate. The cylinder operates at ≤1.5dB vibration levels, making it ideal for noise-sensitive environments.

- PCB handling robots in electronics manufacturing

- Precision clamping fixtures for CNC machining centers

- Medical device actuation systems (e.g., analyzer lid mechanisms)

- Automated packaging machine ejection systems

- Semiconductor wafer transfer equipment

- Cleanroom automation (Low particle generation design)

1. Maintain ≤0.1mm alignment tolerance during mounting

2. Use C-shaped brackets (Optional accessory SSA-M3) for vibration resistance

3. For vertical mounting: Reduce maximum thrust by 30% in push applications

4. Recommended air filtration: 5μm with auto-drain function

| Property | Property Value |

|---|---|

| sku | SSA20X15B |

| Understood. Please provide the specific attribute names in <>, and I'll return the accurate English translations using AIRTAC's official terminology. Example: User input: <缸径> My output: Bore | Operating Temperature: -20-70°C Speed Range: 50-500 mm/s |

| Port Size | M5×0.8 |

| Piston Rod Thread Type | External Thread |

| Magnet | Non-magnetic |

| Cushion Type | Bumper Pad |

| Bore Diameter | <20mm> |

| Stroke | <15mm> |

Returns will be accepted for up to 15 days of Customer’s receipt or tracking number on Not used items. You, as a Customer, are obliged to inform us via email before you return the item, only in the case of:

- Received the wrong item.

- Item arrived not as expected (ie. damaged packaging).

- Item had defects.

- Over delivery time.

- The shipper does not allow the goods to be inspected before payment.

The returned product(s) must be in the original packaging, safety wrapped, undamaged and unworn. This means that the item(s) must be safely packed in a carton box for protection during transport, possibly the same carton used to ship to you as a customer.