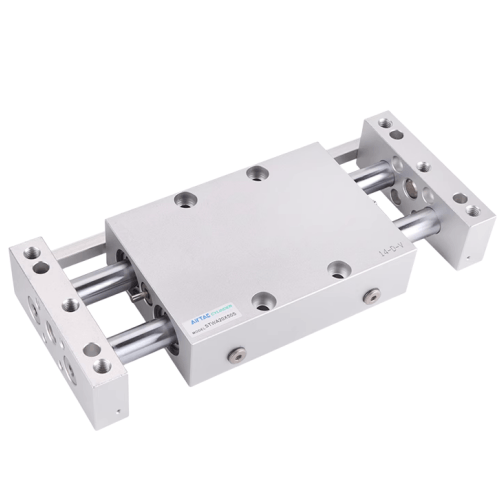

2. Triple air ports (inlet/outlet) configuration provides flexible piping options;

3. Double piston rod structure ensures superior bending resistance and torsional rigidity, capable of withstanding heavy dynamic loads and lateral forces;

4. Integrated oil-cushioned shock absorbers effectively mitigate impact velocity, extending operational lifespan.

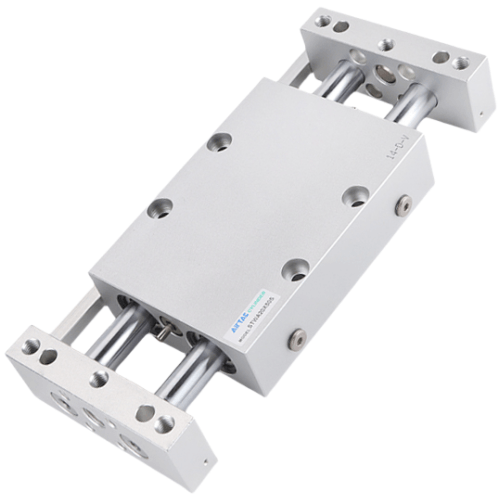

Category: Slide Table Cylinder | Brand: AirTAC | Series: STWA

AirTAC STWA Series Slide Cylinder STWA20X150S Technical Details

- Model: STWA20X150S (Single-axis guide type)

- Bore size: Ø20 mm

- Stroke: 150 mm (±0.5 mm precision)

- Operating pressure: 0.1-0.9 MPa

- Cushioning: Adjustable pneumatic cushion (both ends)

- Mounting: Standard MF1 flange (ISO 15552 compatible)

- Material: Aluminum alloy barrel / Hard anodized piston rod

- Seal type: NBR seals with wear-resistant ring

- Temperature range: -10℃ to 80℃

- Lubrication: Pre-lubricated (Use ISO VG32 turbine oil if maintenance required)

- Weight: 0.82 kg (excluding accessories)

- Dimensions: 260mm(L) × 50mm(W) × 65mm(H) (Full extension length)

- Rod end thread: M6×1.0 internal thread

- Repeat positioning accuracy: ±0.05 mm

- Max theoretical thrust: 31.4N @0.5MPa

- Air consumption: 47.1 cm³/stroke @0.5MPa

Precision-guided slide cylinder with integrated linear bearing system, featuring low-friction operation and exceptional lateral load capacity (up to 9.8N·m). The dual-slot guide rail design prevents rotation during operation while maintaining smooth linear motion. Compatible with magnetic sensors (sensor slot: 6.5mm width).

- PCB board handling in electronics assembly lines

- Precision alignment in optical lens manufacturing

- Component positioning for automated quality inspection systems

- Material transfer in cleanroom environments

- Laser cutting machine nozzle positioning

| Property | Property Value |

|---|---|

| sku | STWA20X150S |

| Mounting Type | Fixed Plate Mounting Type |

| Understood. Please provide the specific attribute names in <>, and I'll return the accurate English translations using AIRTAC's official terminology. Example: User input: <缸径> My output: Bore | Operating Temperature: -20°C to 70°C Speed Range: 30 to 500 mm/s |

| Port Size | M5×0.8 |

| Magnet | S-Magnetic |

| Bore Diameter | <20mm> |

| Stroke | 150mm |

Returns will be accepted for up to 15 days of Customer’s receipt or tracking number on Not used items. You, as a Customer, are obliged to inform us via email before you return the item, only in the case of:

- Received the wrong item.

- Item arrived not as expected (ie. damaged packaging).

- Item had defects.

- Over delivery time.

- The shipper does not allow the goods to be inspected before payment.

The returned product(s) must be in the original packaging, safety wrapped, undamaged and unworn. This means that the item(s) must be safely packed in a carton box for protection during transport, possibly the same carton used to ship to you as a customer.