1. Complies with ISO 21287 standard for highly versatile installation compatibility;

2. Threaded connection between cylinder body and front/rear covers ensures robust structural integrity and convenient maintenance;

3. Precision-machined bore with hard anodized surface treatment delivers exceptional wear resistance and long-term durability;

4. Features asymmetric bidirectional piston seal design with compact dimensions and integrated oil reservoir functionality;

5. Space-optimized structure reduces installation footprint by up to 50% compared to ISO 15552 standard cylinders of equivalent bore size;

6. Three-sided sensor groove configuration on cylinder body enables effortless sensor mounting;

7. Integrated cushioning system effectively absorbs residual energy from high-speed operation and mechanical rotation;

8. Supports multiple mounting configurations with optional accessories.

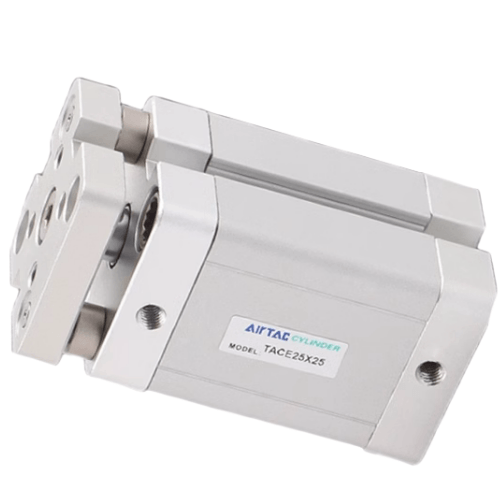

Category: Guide Rod Cylinders | Brand: AIRTAC | Series: TACE

AirTAC TACE63X10S Guided Rod Compact Cylinder Specifications

- Model: TACE63X10S

- Type: Guided rod compact air cylinder (double-acting)

- Bore size: Ø63 mm

- Stroke: 100 mm (standard), customizable up to 300 mm

- Operating pressure: 0.1–0.9 MPa

- Cushioning: Adjustable rubber buffers (both ends)

- Rod type: Hard chrome-plated steel with stainless steel guide rods

- Port size: G1/8 (ISO standard tapered thread)

- Mounting: Standard foot mounting (MF1), optional flange/bracket types

- Temperature range: -20℃ to 80℃

- Seal material: NBR (Nitrile) with wear-resistant ring

- Protection rating: IP54 (standard), IP67 optional

- Weight: 2.5 kg ±3% (without accessories)

- Dimensions: 200mm(L) × 80mm(W) × 80mm(H) (at mid-stroke position)

- Max lateral load: 25 N·m (guide rod moment capacity)

- Piston speed: 50–700 mm/s (lubricated operation)

Precision-guided cylinder combining linear motion with anti-rotation stability. Features dual stainless steel guide rods (Ø12mm) for enhanced moment resistance and alignment accuracy. The T-slot mounting surface enables modular tooling attachments. Optimized for vertical/horizontal installations requiring positional repeatability within ±0.2mm.

- Precision clamping fixtures in CNC machining centers

- Vertical lifting mechanisms in automated assembly lines

- Orientation-critical positioning in semiconductor handling

- Packaging machine gripper alignment systems

- Medical device component pressing operations

| Property | Property Value |

|---|---|

| sku | TACE63X10S |

| Mounting Type | Without Mounting Accessories |

| Understood. Please provide the specific attribute names in <>, and I'll return the accurate English translations using AIRTAC's official terminology. Example: User input: <缸径> My output: Bore | Operating Temperature: -20°C to 70°C Speed Range: 30 to 500 mm/s |

| Port Size | G1/8 |

| Magnet | S-Magnetic |

| Cushion Type | Bumper Pad |

| Bore Diameter | 63mm |

| Stroke | <10mm> |

Returns will be accepted for up to 15 days of Customer’s receipt or tracking number on Not used items. You, as a Customer, are obliged to inform us via email before you return the item, only in the case of:

- Received the wrong item.

- Item arrived not as expected (ie. damaged packaging).

- Item had defects.

- Over delivery time.

- The shipper does not allow the goods to be inspected before payment.

The returned product(s) must be in the original packaging, safety wrapped, undamaged and unworn. This means that the item(s) must be safely packed in a carton box for protection during transport, possibly the same carton used to ship to you as a customer.