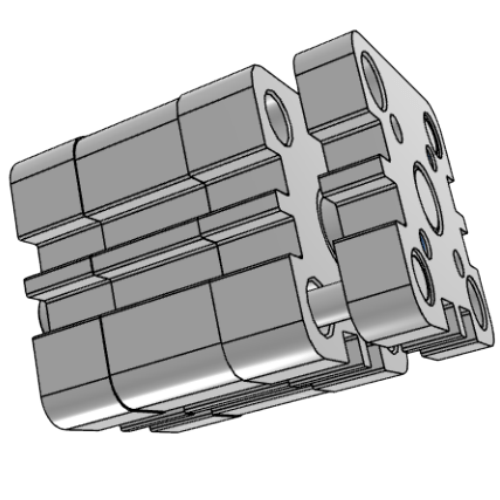

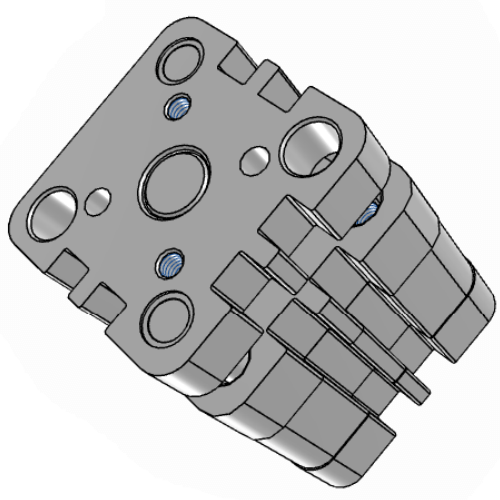

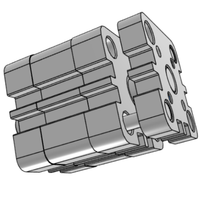

2. Threaded connection between cylinder barrel and end covers ensures high structural integrity and ease of maintenance;

3. Precision-machined bore with hard anodized treatment delivers exceptional wear resistance and durability;

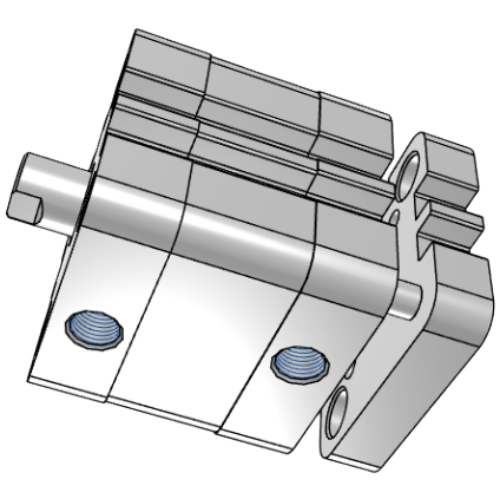

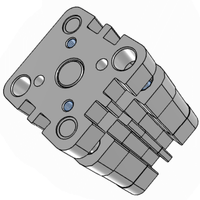

4. Patented asymmetric bidirectional sealing configuration on piston combines compact dimensions with integrated oil reservoir function;

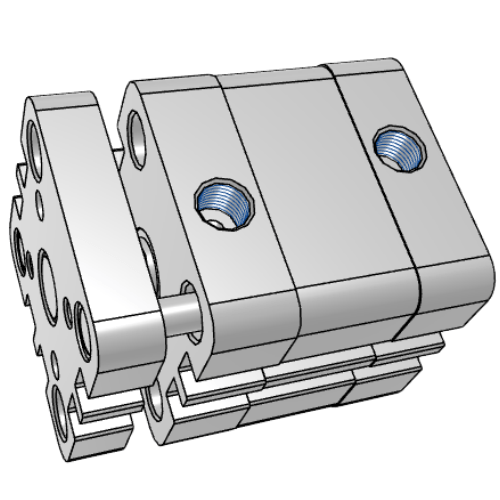

5. Space-saving design achieves 50% reduction in installation footprint compared to ISO 15552 standard cylinders of equivalent bore size;

6. Three-sided sensor slots on the barrel facilitate seamless sensor integration;

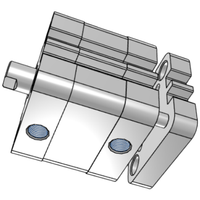

7. Integrated shock-absorbing pads effectively dissipate residual energy from high-speed operation and mechanical rotation;

8. Comprehensive selection of mounting accessories available in multiple configurations.

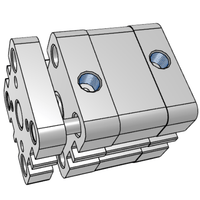

Category: Guided Cylinders , Brand: AirTAC , Series: TACED

AirTAC TACED100X50S Guided Rod Compact Cylinder Specifications

- Model: TACED100X50S

- Type: Double-acting guided rod cylinder

- Bore size: 100mm

- Stroke: 50mm (±0.5mm tolerance)

- Operating pressure: 0.05-1.0 MPa

- Cushioning: Rubber + adjustable buffer

- Guide rod type: Stainless steel precision shaft (HRC60±2 hardness)

- Port size: G1/2 (NPT1/2 optional)

- Mounting style: Front flange (MF1) with 4x M8 threaded holes

- Temperature range: -20℃ to 80℃ (dry air required below 0℃)

- Cylinder material: Aluminum alloy (anodized surface)

- Seal material: NBR/PU (standard), FKM available for high temp

- Weight: 5.8kg ±2% (without accessories)

- Dimensions: 345mm(L) × 145mm(W) × 125mm(H)

- Rod end thread: M16×1.5 (male)

- Protection rating: IP54 (standard), IP67 with optional wiper

High-rigidity guided cylinder featuring dual stainless steel shafts for precise linear motion control. The TACED series combines compact footprint with exceptional anti-rotation capability (maximum torque resistance: 450N·m). Integrated shock absorbers reduce end-impact noise to ≤70dB. Compatible with auto-switch sensors (mounting grooves pre-machined).

- Precision alignment in robotic welding stations

- Vertical lifting mechanisms for conveyor transfers

- Clamping fixtures for CNC machining centers

- Palletizing robot end-effector positioning

- Automated optical inspection (AOI) equipment

- Relubricate guide rods every 500km of cumulative travel

- Inspect buffer seals every 1 million cycles

- Replace wear bands at 0.5mm rod deflection measurement

| Property | Property Value |

|---|---|

| sku | TACED100X50S |

| Mounting Type | Without Mounting Accessories |

| Understood. Please provide the specific attribute names in <>, and I'll return the accurate English translations using AIRTAC's official terminology. Example: User input: <缸径> My output: Bore | Operating Temperature: -20°C to 70°C Speed Range: 30 to 500 mm/s |

| Port Size | G1/8 |

| Magnet | S-Magnetic |

| Cushion Type | Bumper Pad |

| Bore Diameter | 100mm |

| Stroke | <50mm> |

Returns will be accepted for up to 15 days of Customer’s receipt or tracking number on Not used items. You, as a Customer, are obliged to inform us via email before you return the item, only in the case of:

- Received the wrong item.

- Item arrived not as expected (ie. damaged packaging).

- Item had defects.

- Over delivery time.

- The shipper does not allow the goods to be inspected before payment.

The returned product(s) must be in the original packaging, safety wrapped, undamaged and unworn. This means that the item(s) must be safely packed in a carton box for protection during transport, possibly the same carton used to ship to you as a customer.