2. Sliding bearings: Ideal for applications requiring radial load resistance such as braking operations, delivering enhanced torsional stiffness; Linear bearings: Optimized for pushing/lifting actions or scenarios demanding high precision, heavy load capacity, and particularly suitable for low-friction movement requirements;

3. Specially engineered guide frame body enables multi-directional mounting configurations for flexible installation.

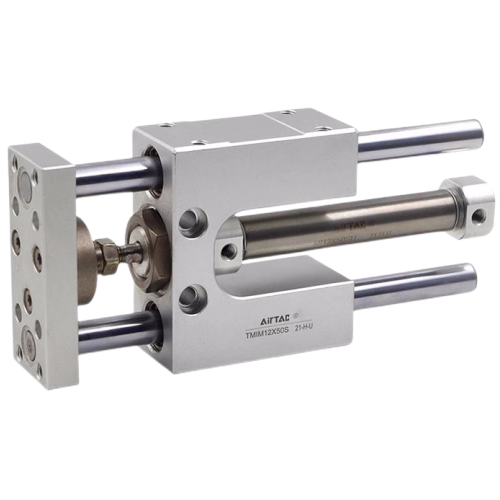

Category: Guide Rod Cylinder , Brand: Airtac , Series: TMIC

AirTAC TMICL25X125 Guided Rod Cylinder Specifications

- Model: TMICL25X125

- Type: Double-acting guided cylinder with integrated linear bearing

- Bore size: 25mm

- Stroke: 125mm (±0.5mm tolerance)

- Operating pressure: 0.05–1.0 MPa

- Piston speed: 50–800 mm/s

- Cushioning: Adjustable rubber buffers (both ends)

- Mounting: Standard MF1 flange with 4×M5 threaded holes

- Rod end thread: M10×1.25 (external)

- Port size: G1/8 (NPT1/8 optional)

- Ambient temperature: -10℃ to 80℃

- Seal material: NBR (Nitrile) with wear-resistant guide rings

- Rod material: Hard chrome-plated steel

- Body material: Aluminum alloy (A6063-T5)

- Guide mechanism: Dual stainless steel shafts (Ø12mm)

- Weight: 1.24 kg (without accessories)

- Dimensions: 200mm(L) × 80mm(W) × 85mm(H)

- Repeat positioning accuracy: ±0.05mm

- Max lateral load: 45N

- Max moment load: 8N·m

- ISO standard: 15552

- Sensor compatibility: M9/M12 proximity switches (optional groove)

Precision-guided pneumatic cylinder featuring dual stainless steel shafts for enhanced moment resistance and alignment stability. The integrated linear bearings eliminate rotational movement, making it ideal for vertical mounting applications. Pre-lubricated with AT-10H grease for maintenance-free operation up to 3,000km travel distance.

- Precision alignment in semiconductor handling robots

- Vertical lifting mechanisms in automated packaging lines

- Fixture positioning for CNC machine tooling

- Glass panel transfer systems requiring anti-rotation

- Pharmaceutical tablet press ejection mechanisms

| Property | Property Value |

|---|---|

| sku | TMICL25X125 |

| Port Size | PT1/8 |

| Bore Diameter | <25 mm> |

| Bearing Category | Linear Bearing |

Returns will be accepted for up to 15 days of Customer’s receipt or tracking number on Not used items. You, as a Customer, are obliged to inform us via email before you return the item, only in the case of:

- Received the wrong item.

- Item arrived not as expected (ie. damaged packaging).

- Item had defects.

- Over delivery time.

- The shipper does not allow the goods to be inspected before payment.

The returned product(s) must be in the original packaging, safety wrapped, undamaged and unworn. This means that the item(s) must be safely packed in a carton box for protection during transport, possibly the same carton used to ship to you as a customer.