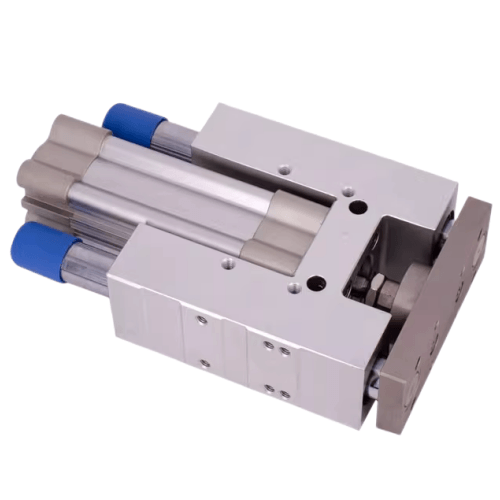

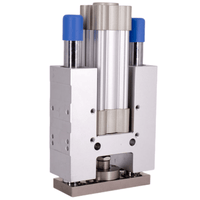

1. Dual bearing options:

- Slide bearings for high radial load capacity and superior torsional rigidity, ideal for braking applications requiring lateral stability.

- Linear bearings optimized for precision lifting operations, high-load scenarios, and low-friction movement requirements.

2. Multi-axis mounting system: The reinforced guide frame structure supports flexible installation configurations across multiple planes.

3. Advanced motion control: Features an adjustable cushioning mechanism for smooth stroke termination and vibration reduction.

4. Smart sensing integration: Equipped with adjustable sensor mounting brackets enabling customizable positioning for proximity detection systems.

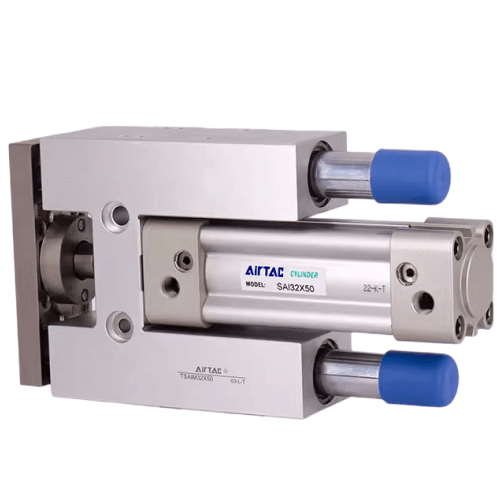

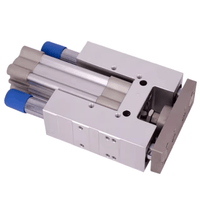

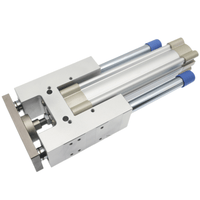

Category: Guide Rod Cylinders | Brand: AIRTAC | Series: TSAIL

AirTAC TSAIL63X150S Guided Rod Cylinder Specifications

- Model: TSAIL63X150S

- Bore size: 63mm

- Stroke: 150mm

- Mounting type: Standard MF1/MF2 flange (ISO 15552 compatible)

- Rod end type: External thread M20×1.5

- Operating pressure: 0.05–1.0 MPa

- Piston speed: 50–800 mm/s

- Cushioning: Adjustable air cushion (both ends)

- Seal material: NBR + PU combination

- Ambient temperature: -10℃ to 80℃

- Lubrication: Pre-lubricated (Oil-free operation possible)

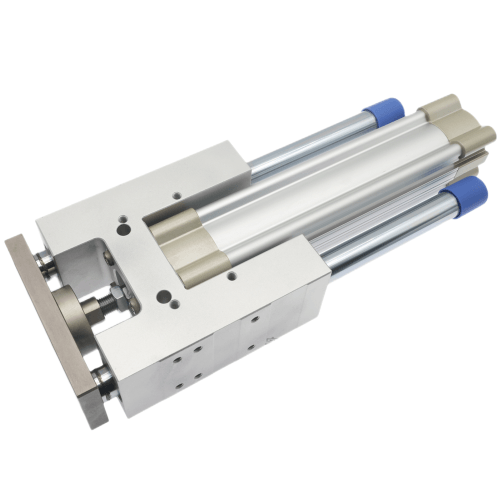

- Guide mechanism: Dual linear ball bearings

- Repeat positioning accuracy: ±0.1mm

- Weight: 3.8kg (excluding accessories)

- Dimensions: 268mm(L) × 90mm(W) × 90mm(H)

- Rod diameter: 20mm

- Protection rating: IP54 (standard), IP67 optional

Precision guided rod cylinder featuring integrated linear guidance system for enhanced moment load resistance. The TSAIL series combines traditional pneumatic actuation with machine tool-grade positioning stability, utilizing hardened steel guide shafts and preloaded ball bushings. Includes magnetic piston for position sensing compatibility.

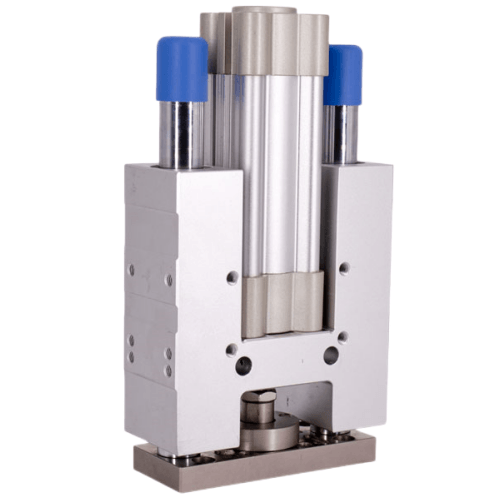

- Precision workpiece clamping in CNC fixtures

- Vertical lifting mechanisms in assembly robots

- Press-fit operations in electronic component manufacturing

- Material handling systems requiring anti-rotation stability

- Automated inspection equipment positioning stages

1. Mount on machined surface with flatness ≤0.1mm/m

2. Use flexible couplings when connecting to rigid mechanisms

3. Maintain 0.5-1% lubricator oil concentration in air supply

4. Alignment tolerance: ≤0.05mm perpendicularity between rod and load

5. Recommended re-lubrication interval: 500km travel distance

| Property | Property Value |

|---|---|

| sku | TSAIL63X150S |

| Understood. Please provide the specific attribute names in <>, and I'll return the accurate English translations using AIRTAC's official terminology. Example: User input: <缸径> My output: Bore | Operating Temperature: -20°C to 70°C Speed Range: 30 to 500 mm/s |

| Port Size | PT3/8 |

| Magnet | S-Magnetic |

| Cushion Type | Adjustable Cushioning |

| Bore Diameter | 63mm |

| Stroke | 150mm |

| Bearing Category | Linear Bearing |

Returns will be accepted for up to 15 days of Customer’s receipt or tracking number on Not used items. You, as a Customer, are obliged to inform us via email before you return the item, only in the case of:

- Received the wrong item.

- Item arrived not as expected (ie. damaged packaging).

- Item had defects.

- Over delivery time.

- The shipper does not allow the goods to be inspected before payment.

The returned product(s) must be in the original packaging, safety wrapped, undamaged and unworn. This means that the item(s) must be safely packed in a carton box for protection during transport, possibly the same carton used to ship to you as a customer.