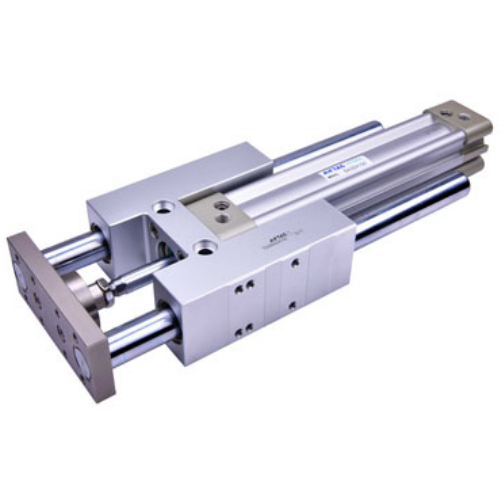

1. The TSAIM series represents an innovative integration of a guide frame and cylinder, delivering enhanced structural stability and functional versatility.

2. Bearing options optimized for diverse applications:

- Slide bearings: Engineered for radial load resistance in braking scenarios, offering superior torsional rigidity.

- Linear bearings: Ideal for pushing/lifting operations requiring high precision, heavy load capacity, and minimal friction applications.

3. Multi-axis mounting configurations enabled by the guide frame's proprietary design, ensuring flexible installation adaptability.

4. Precision cushioning adjustment system guarantees smooth stroke termination and operational stability.

5. Modular sensor mounting base allows positional customization to meet diverse sensing requirements.

Category: Guide Rod Cylinders | Brand: AirTAC | Series: TSAIM

AirTAC TSAIM80X350S Guided Rod Cylinder Specifications

- Model: TSAIM80X350S

- Type: Double-acting guided cylinder with adjustable stopper

- Bore size: Ø80 mm

- Stroke: 350 mm (customizable 250-500mm)

- Operating pressure: 0.05-1.0 MPa

- Medium temperature: -20℃ to 80℃

- Cushioning: Adjustable pneumatic cushion (both ends)

- Mounting type: MF1 front flange mounting

- Port size: G1/2 (NPT1/2 optional)

- Piston rod thread: M20×1.5

- Guide mechanism: Dual-axis adjustable linear guide block

- Material:

- Cylinder tube: Aluminum alloy hard anodized

- Piston rod: Chrome-plated steel (Cr-Mo)

- End covers: Cast aluminum

- Seals: HNBR with wear-resistant ring

- Weight: 9.8 kg ±3%

- Dimensions:

- Length: 620 mm (including rod)

- Width: 142 mm (guide block span)

- Height: 105 mm (mounting base to top)

- Protection class: IP54 (standard), IP67 optional

- Lubrication: Pre-lubricated (relubrication every 2,000km stroke)

Heavy-duty guided cylinder with integrated linear motion control, featuring precision-ground guide rails and adjustable mechanical stoppers. The dual-axis guidance system eliminates rotational torque during operation, making it ideal for precise vertical load handling. Includes wear indicator marks on guide blocks and corrosion-resistant coating for harsh environments.

- Vertical press mechanisms in stamping machines

- Precision alignment systems for glass panel handling

- Automated welding fixture positioning

- Die-casting machine ejection units

- Plastic injection molding clamp systems

- Maximum piston speed: 800 mm/s

- Static load moment: 450 N·m

- Repeat positioning accuracy: ±0.15 mm

- Minimum mounting base thickness: 15mm steel plate

| Property | Property Value |

|---|---|

| sku | TSAIM80X350S |

| Port Size | PT3/8 |

| Bore Diameter | 80 mm |

Returns will be accepted for up to 15 days of Customer’s receipt or tracking number on Not used items. You, as a Customer, are obliged to inform us via email before you return the item, only in the case of:

- Received the wrong item.

- Item arrived not as expected (ie. damaged packaging).

- Item had defects.

- Over delivery time.

- The shipper does not allow the goods to be inspected before payment.

The returned product(s) must be in the original packaging, safety wrapped, undamaged and unworn. This means that the item(s) must be safely packed in a carton box for protection during transport, possibly the same carton used to ship to you as a customer.