2. Wide pressure range adaptability – options include Ultra-High Pressure (X), High Pressure (H), Standard, and Large Flow (L) configurations;

3. Compact structure with minimized footprint, lightweight design, and tool-free assembly/disassembly capability;

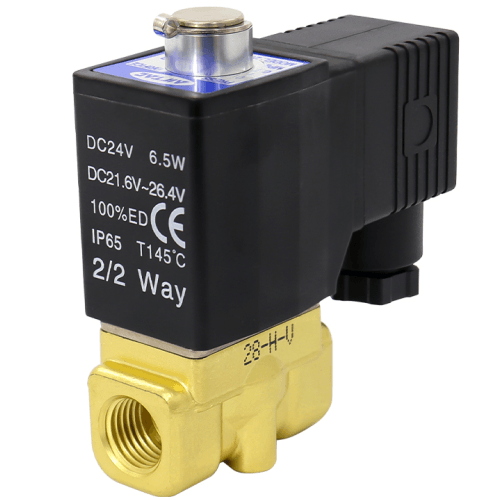

4. Brass valve body construction with Class B thermal-rated coil. Standard FPM (Fluorocarbon Rubber) seals ensure compatibility with multiple media. Custom seal materials available upon consultation with our technical department;

5. IP65-rated coil protection, available in direct lead wire or DIN connector wiring configurations.

Category: Fluid Solenoid Valves | Brand: AirTAC | Series: 2KWX Series

AirTAC 2KWX03006C Fluid Solenoid Valve Technical Details

- Model: 2KWX03006C

- Type: 2-position, 3-way normally closed (direct-acting)

- Port size: G1/8 (ISO228 standard)

- Fluid compatibility: Hydraulic oil, water-glycol, air (lubricated)

- Operating pressure range: 0.02–31.5 MPa (vacuum to 315 bar)

- Voltage variants: DC12V (±10%), DC24V (±10%), AC110V (50/60Hz), AC220V (50/60Hz)

- Power consumption: 2.2W (DC), 3.5VA (AC)

- Response time: ≤15ms (energize), ≤20ms (de-energize)

- Seal materials: HNBR (hydrogenated nitrile) + FKM (fluorocarbon)

- Temperature tolerance: -30℃ to 120℃ (fluid temp), -10℃ to 60℃ (ambient)

- Flow rate: 30 L/min (at 0.5MPa pressure drop)

- Weight: 450g ±5% (including coil)

- Dimensions: 76mm(L) × 45mm(W) × 64mm(H) (excluding fittings)

- Protection class: IP67 (coil), IP65 (valve body)

- Electrical connection: DIN43650 Form A connector

High-pressure fluid control valve engineered for aggressive media handling, featuring dual-seal technology with corrosion-resistant stainless steel plunger. The zero-leakage design incorporates pressure-balancing chambers to minimize coil load. Compatible with ISO VG32-68 hydraulic oils and requires minimum 10μm filtration. Includes manual override for system debugging.

- Hydraulic press clutch/brake systems

- CNC machine tool coolant control

- Food processing CIP (Clean-in-Place) valve clusters

- Off-highway vehicle steering hydraulics

- Pharmaceutical batch reactor fluid routing

| Property | Property Value |

|---|---|

| sku | 2KWX03006C |

| Port Size | PT1/8 |

| Flow Aperture | 1.5mm |

| Coil Voltage | AC 110V |

Returns will be accepted for up to 15 days of Customer’s receipt or tracking number on Not used items. You, as a Customer, are obliged to inform us via email before you return the item, only in the case of:

- Received the wrong item.

- Item arrived not as expected (ie. damaged packaging).

- Item had defects.

- Over delivery time.

- The shipper does not allow the goods to be inspected before payment.

The returned product(s) must be in the original packaging, safety wrapped, undamaged and unworn. This means that the item(s) must be safely packed in a carton box for protection during transport, possibly the same carton used to ship to you as a customer.