2. Features threaded connections at both ends of the cylinder barrel for enhanced structural integrity and maintenance convenience;

3. Precision-machined interior with hard anodization treatment for superior wear resistance and durability;

4. Patented bidirectional sealing structure on piston ensures compact dimensions and integrated oil retention capability;

5. Space-saving compact design optimizes installation footprint;

6. Magnetic sensor groove along cylinder periphery enables flexible sensor mounting;

7. Multiple mounting accessories available for various configurations;

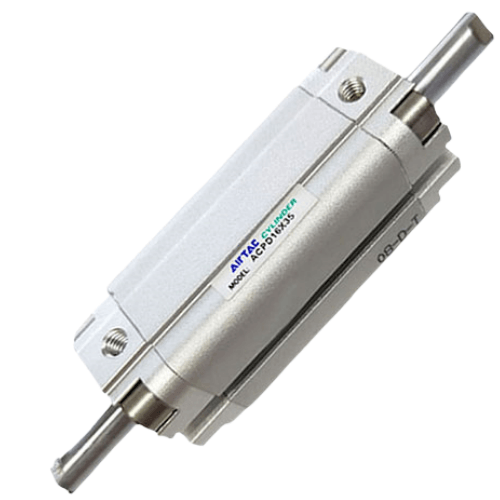

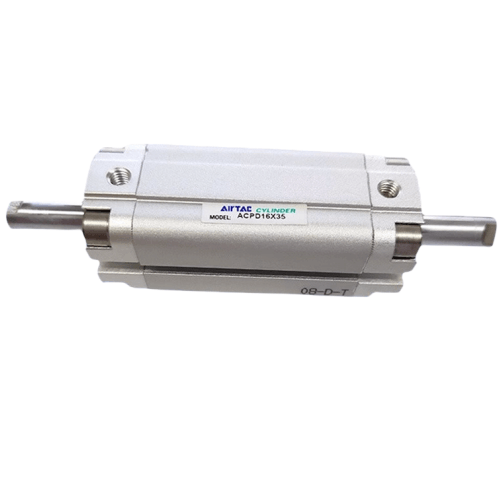

Category: Double-acting Cylinder | Brand: AirTAC | Series: ACPD

AirTAC ACPD100X90B Double Rod Compact Cylinder Specifications

- Model: ACPD100X90B

- Type: Double rod compact cylinder (ISO 6432 compliant)

- Bore size: 100mm

- Stroke: 90mm (±0.5mm tolerance)

- Mounting type: Basic/Foot-mount (optional flange/bracket kits available)

- Port size: G3/8 (1/2 NPT optional)

- Operating pressure: 0.1-1.0 MPa

- Cushioning: Adjustable pneumatic cushion (both ends)

- Piston speed: 50-750 mm/s (lubricated condition)

- Ambient temperature: -20℃ to 80℃

- Material:

- Cylinder tube: Aluminum alloy (hard anodized)

- Piston rod: SUS304 stainless steel (chrome-plated)

- Seals: NBR standard (Viton/PU optional)

- Weight: 5.8kg (excluding accessories)

- Dimensions: 282mm(L) × 140mm(W) × 140mm(H) (fully retracted)

- Protection rating: IP65 (standard rod wiper)

- Air consumption: 7.85L/stroke @ 0.5MPa

High-rigidity twin rod cylinder featuring symmetrical force output and minimal deflection. The through-rod design eliminates rotational torque while maintaining 90% space efficiency compared to standard cylinders. Integrated shock absorbers with 15° adjustable cushion needles prevent end-impact in high-cycle applications. Optional magnetic piston version (ACPD100X90B-M9) available for position sensing.

- Precision clamping fixtures in CNC machining centers

- Vertical lifting mechanisms for conveyor transfer systems

- Simultaneous door actuation in industrial ovens

- Parallel gripper actuation in robotic EOAT systems

- Balanced force applications in glass tempering lines

- Allow 0.5mm alignment tolerance per 100mm stroke during mounting

- Use M6 mounting screws with 12mm minimum engagement depth

- Maintain 1:200 slope for horizontal installations to ensure drainage

- Lubricate with ISO VG32 hydraulic oil if using non-lubricated air

Inspect rod seals every 500,000 cycles in clean environments (every 200,000 cycles in abrasive conditions). Replace cushion seals when cushion adjustment exceeds 3 full turns from initial setting. Maximum side load capacity: 180N at mid-stroke.

| Property | Property Value |

|---|---|

| sku | ACPD100X90B |

| Mounting Type | Without Mounting Accessories |

| Understood. Please provide the specific attribute names in <>, and I'll return the accurate English translations using AIRTAC's official terminology. Example: User input: <缸径> My output: Bore | Operating Temperature: -20°C to 70°C Speed Range: 30 to 500 mm/s |

| Port Size | G1/4" Thread |

| Piston Rod Thread Type | External Thread |

| Magnet | Non-magnetic |

| Bore Diameter | 100mm |

| Stroke | 90mm |

Returns will be accepted for up to 15 days of Customer’s receipt or tracking number on Not used items. You, as a Customer, are obliged to inform us via email before you return the item, only in the case of:

- Received the wrong item.

- Item arrived not as expected (ie. damaged packaging).

- Item had defects.

- Over delivery time.

- The shipper does not allow the goods to be inspected before payment.

The returned product(s) must be in the original packaging, safety wrapped, undamaged and unworn. This means that the item(s) must be safely packed in a carton box for protection during transport, possibly the same carton used to ship to you as a customer.