2. Features threaded connections at both ends of the cylinder barrel for enhanced structural integrity and maintenance convenience;

3. Precision-machined interior with hard anodization treatment for superior wear resistance and durability;

4. Patented bidirectional sealing structure on piston ensures compact dimensions and integrated oil retention capability;

5. Space-saving compact design optimizes installation footprint;

6. Magnetic sensor groove along cylinder periphery enables flexible sensor mounting;

7. Multiple mounting accessories available for various configurations;

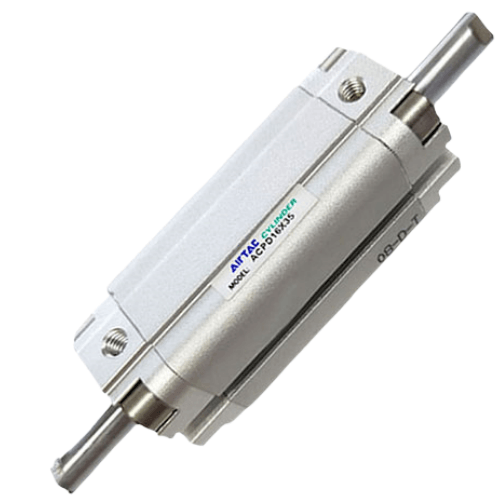

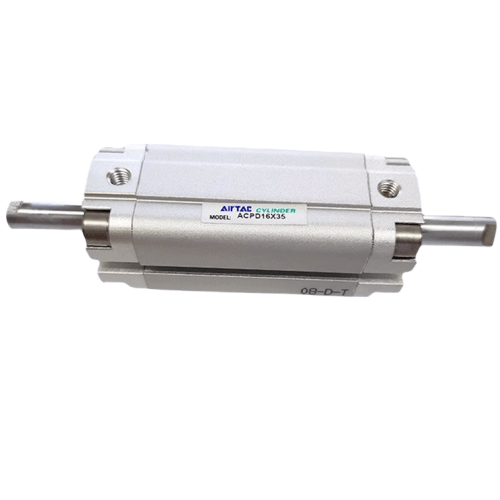

Category: Double-acting Cylinder | Brand: AirTAC | Series: ACPD

AirTAC ACPD63X5S Double Rod Compact Cylinder Specifications

- Model: ACPD63X5S

- Type: Double-acting dual rod compact cylinder

- Bore size: 63mm

- Stroke: 5mm (Standard), customizable up to 100mm

- Operating pressure: 0.1-0.9 MPa

- Temperature range: -20℃ to 80℃

- Cushioning type: Adjustable rubber buffers (both ends)

- Mounting style: Basic type (MF1), optional foot/rod-end mounts

- Port size: M5x0.8 (G1/8 adapter available)

- Piston rod thread: M10x1.25

- Material: Aluminum alloy body, chrome-plated stainless steel rod

- Seal material: NBR (Nitrile) seals standard, optional FKM/Viton

- Weight: 1.25kg (without accessories)

- Dimensions:

- Length: 154mm (basic length at 5mm stroke)

- Width: 78mm (including mounting bosses)

- Height: 63mm (barrel diameter)

- ISO standard: 6431 (VDMA 24562, NF E49 003.1)

- Lubrication: Pre-lubricated (Oil-free operation possible)

- Repeat accuracy: ±0.5mm

- Protection rating: IP65 (wipers included)

Designed for precision linear motion in confined spaces, the ACPD63X5S features synchronized dual rod movement with anti-rotation stability. Its anodized barrel resists corrosion in humid environments, while the magnetic piston enables position sensing compatibility. The cylinder operates at speeds up to 1.0 m/s with optimized cushioning to minimize end-impact noise.

- Precision clamping fixtures in CNC machining centers

- Material gate control in packaging machinery

- Z-axis actuation in 3D printing/pick-and-place systems

- Valve switching mechanisms in chemical processing

- Test equipment requiring symmetrical force application

- Align rods parallel to motion axis within 0.2mm/m tolerance

- Use flexible couplings for stroke >50mm applications

- For vertical mounting, specify optional rod lock nut (AC-LN10)

- Maintain 0.5mm minimum clearance between rods and surrounding components

| Property | Property Value |

|---|---|

| sku | ACPD63X5S |

| Mounting Type | Without Mounting Accessories |

| Understood. Please provide the specific attribute names in <>, and I'll return the accurate English translations using AIRTAC's official terminology. Example: User input: <缸径> My output: Bore | Operating Temperature: -20°C to 70°C Speed Range: 30 to 500 mm/s |

| Port Size | G1/8 |

| Piston Rod Thread Type | Internal Thread |

| Magnet | S-Magnetic |

| Bore Diameter | 63mm |

| Stroke | <5mm> |

Returns will be accepted for up to 15 days of Customer’s receipt or tracking number on Not used items. You, as a Customer, are obliged to inform us via email before you return the item, only in the case of:

- Received the wrong item.

- Item arrived not as expected (ie. damaged packaging).

- Item had defects.

- Over delivery time.

- The shipper does not allow the goods to be inspected before payment.

The returned product(s) must be in the original packaging, safety wrapped, undamaged and unworn. This means that the item(s) must be safely packed in a carton box for protection during transport, possibly the same carton used to ship to you as a customer.