2. Features threaded connections at both ends of the cylinder barrel for enhanced structural integrity and maintenance convenience;

3. Precision-machined interior with hard anodization treatment for superior wear resistance and durability;

4. Patented bidirectional sealing structure on piston ensures compact dimensions and integrated oil retention capability;

5. Space-saving compact design optimizes installation footprint;

6. Magnetic sensor groove along cylinder periphery enables flexible sensor mounting;

7. Multiple mounting accessories available for various configurations;

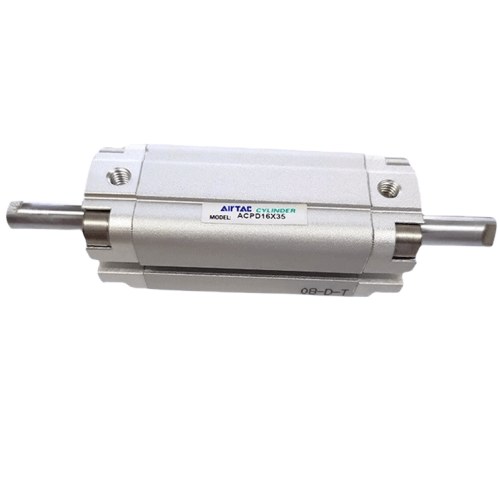

Category: Double-acting Cylinder | Brand: AirTAC | Series: ACPD

AirTAC ACPD80X125S Double Rod Compact Cylinder Specifications

- Model: ACPD80X125S

- Type: Double-rod compact cylinder (ISO 6432 compliant)

- Bore size: 80 mm

- Stroke: 125 mm

- Operating pressure: 0.1~0.9 MPa

- Cushion type: Adjustable cushion at both ends

- Port size: G3/8 (standard), optional NPT1/2

- Piston rod material: Chrome-plated stainless steel (SUS304)

- Cylinder tube: Hard anodized aluminum alloy

- Seal material: NBR (Nitrile rubber)

- Temperature range: -20℃ to 80℃

- Weight: 3.5 kg (bare cylinder), 3.8 kg with accessories

- Dimensions:

- Total length: 205 mm (at mid-stroke)

- Body diameter: 90 mm

- Rod diameter: 20 mm (per rod)

- Mounting hole spacing: 160×160 mm (front flange pattern)

- Max theoretical thrust: 452 N @ 0.63 MPa

- Lubrication: Pre-lubricated (optional oil-free operation)

- Protection rating: IP40 (standard), IP67 with optional wiper seals

The ACPD80X125S features a space-saving dual-rod design with symmetrical force output, ideal for precision alignment tasks. Its hardened aluminum construction ensures corrosion resistance while maintaining 50% lighter weight than steel cylinders. The through-rod design allows position sensing at both ends and enables optional mid-position mounting.

- Simultaneous clamping/unclamping in CNC fixture systems

- Precision web tension control in printing machinery

- Parallel lifting mechanisms in automotive assembly

- Material transfer gates in packaging lines

- Counterbalance systems for robotic arms

- Use alignment jigs during mounting to prevent rod binding

- Maintain 0.5-1mm clearance between rods and adjacent components

- For vertical installations, specify "UP" marked end as top position

- Recommended cycle rate: ≤200 mm/s with full cushion adjustment

Accessory Compatibility: Supports AT-MPU magnetic sensors (3-wire DC type), adjustable rod locks (ALQ series), and heat-resistant seals (-HR variant for 120℃ operations). Requires 5μm filtered air with ISO 8573-1:2010 Class 3.4.2 air quality.

| Property | Property Value |

|---|---|

| sku | ACPD80X125S |

| Mounting Type | Without Mounting Accessories |

| Understood. Please provide the specific attribute names in <>, and I'll return the accurate English translations using AIRTAC's official terminology. Example: User input: <缸径> My output: Bore | Operating Temperature: -20°C to 70°C Speed Range: 30 to 500 mm/s |

| Port Size | G1/8 |

| Piston Rod Thread Type | Internal Thread |

| Magnet | S-Magnetic |

| Bore Diameter | 80 mm |

| Stroke | 125mm |

Returns will be accepted for up to 15 days of Customer’s receipt or tracking number on Not used items. You, as a Customer, are obliged to inform us via email before you return the item, only in the case of:

- Received the wrong item.

- Item arrived not as expected (ie. damaged packaging).

- Item had defects.

- Over delivery time.

- The shipper does not allow the goods to be inspected before payment.

The returned product(s) must be in the original packaging, safety wrapped, undamaged and unworn. This means that the item(s) must be safely packed in a carton box for protection during transport, possibly the same carton used to ship to you as a customer.