2. Features C-shaped retaining rings for cylinder body and end cap fixation, with a riveted piston-rod structure for compactness and reliability;

3. Precision honed cylinder bore ensures superior wear resistance and extended durability;

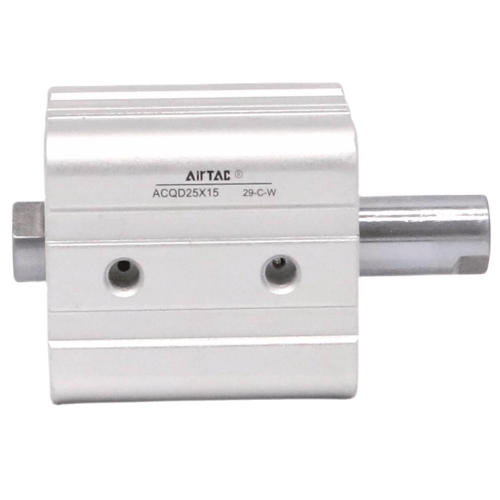

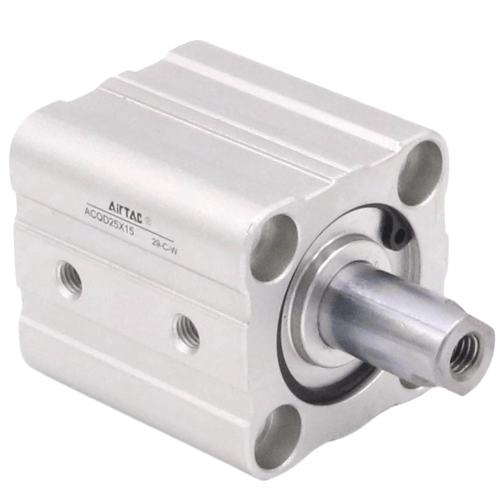

4. Extended guide distance on front end cap enhances guiding performance;

5. Ultra-slim profile design optimizes space utilization in confined installations;

6. Integrated sensor grooves around the cylinder body simplify sensor mounting;

7. Multiple mounting accessories available for versatile configurations;

Category: Double Rod Cylinders | Brand: Airtac | Series: ACQD

AirTAC ACQD25X75S Double Rod Compact Cylinder Specifications

- Model: ACQD25X75S

- Type: ISO 6432 compliant double-rod compact cylinder

- Bore size: 25 mm

- Stroke: 75 mm (±0.5 mm tolerance)

- Operating pressure: 0.05–1.0 MPa

- Temperature range: -20℃ to 80℃

- Cushioning: Adjustable elastic buffer (both ends)

- Mounting: Basic type (no built-in mount, requires bracket)

- Port size: M5x0.8 (standard) / NPT1/8 (optional)

- Piston rod thread: M6x1.0 (double extended rods)

- Material: Aluminum alloy barrel, hardened steel rods

- Seals: NBR (standard) / FKM (high-temp option)

- Rod stroke tolerance: ±1.5 mm (full stroke)

- Dual rod length symmetry: ≤0.2 mm variance

- Weight: 0.62 kg (with magnetic piston for sensor detection)

- Dimensions: 115mm(L) × 34mm(W) × 34mm(H) (barrel only)

- Full extended length: 190mm (75mm stroke + base length)

Ultra-slim profile cylinder (34mm square cross-section) designed for space-constrained automation systems. Features synchronized dual-rod motion for balanced force transmission and position stability. Integrated magnet in piston enables non-contact position sensing. Corrosion-resistant anodized finish with IP65 protection rating.

- Precision alignment in semiconductor wafer handling

- Simultaneous clamping in CNC fixture systems

- Linear guide actuation in 3D printer mechanisms

- Packaging machine stopper controls

- Robotic end-effector position locking

1. Use rigid mounting brackets (L-type recommended) to prevent torsion

2. Maintain 0.5-1mm clearance between rods and load connection points

3. Lubricate with ISO VG32 hydraulic oil if operating below 0.3 MPa

4. For vertical mounting: Reduce max payload by 30% to prevent rod buckling

| Property | Property Value |

|---|---|

| sku | ACQD25X75S |

| Mounting Type | Without Mounting Accessories |

| Understood. Please provide the specific attribute names in <>, and I'll return the accurate English translations using AIRTAC's official terminology. Example: User input: <缸径> My output: Bore | Operating Temperature: -20°C to 70°C Speed Range: 30 to 500 mm/s |

| Port Size | M5×0.8 |

| Piston Rod Thread Type | Internal Thread |

| Magnet | S-Magnetic |

| Bore Diameter | <25 mm> |

| Stroke | 75mm |

Returns will be accepted for up to 15 days of Customer’s receipt or tracking number on Not used items. You, as a Customer, are obliged to inform us via email before you return the item, only in the case of:

- Received the wrong item.

- Item arrived not as expected (ie. damaged packaging).

- Item had defects.

- Over delivery time.

- The shipper does not allow the goods to be inspected before payment.

The returned product(s) must be in the original packaging, safety wrapped, undamaged and unworn. This means that the item(s) must be safely packed in a carton box for protection during transport, possibly the same carton used to ship to you as a customer.