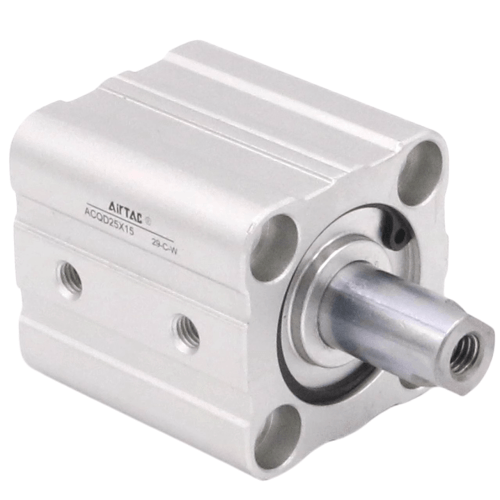

2. Features C-shaped retaining rings for cylinder body and end cap fixation, with a riveted piston-rod structure for compactness and reliability;

3. Precision honed cylinder bore ensures superior wear resistance and extended durability;

4. Extended guide distance on front end cap enhances guiding performance;

5. Ultra-slim profile design optimizes space utilization in confined installations;

6. Integrated sensor grooves around the cylinder body simplify sensor mounting;

7. Multiple mounting accessories available for versatile configurations;

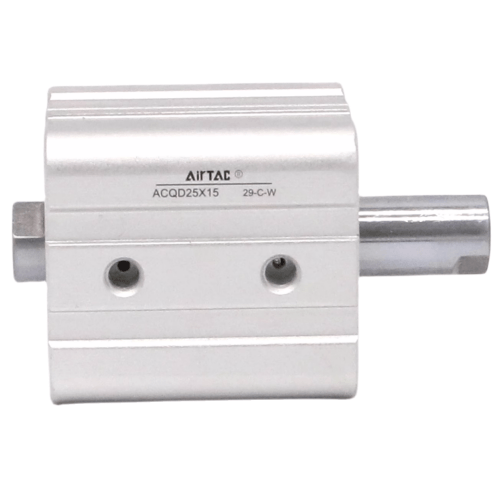

Category: Double Rod Cylinders | Brand: Airtac | Series: ACQD

AirTAC ACQD32X100S Double Rod Compact Cylinder Specifications

- Model: ACQD32X100S

- Type: Double-acting, dual rod compact cylinder

- Bore size: 32mm

- Stroke: 100mm

- Operating pressure: 0.1–0.9 MPa

- Cushion type: Adjustable rubber cushion (both ends)

- Piston speed: 50–800 mm/s

- Port size: Rc1/8 (NPT1/8 optional)

- Ambient temperature: -20℃ to 80℃

- Seal material: NBR (Nitrile rubber)

- Piston material: Aluminum alloy with hard anodizing

- Rod material: Stainless steel (SUS304)

- Mounting type: Basic type (MF1) with axial mounting holes

- Weight: 1.2kg (excluding accessories)

- Dimensions:

- Total length (L): 178mm (stroke 100 + 78mm base)

- Width (W): 42mm (mounting bracket width)

- Height (H): 32mm (cylinder body height)

- Accessory options: Magnetic switch (D-A93), rod end fittings

- ISO standard: Compliant with ISO 6432 (mounting dimensions)

Ultra-slim profile cylinder featuring symmetrical dual rod design for balanced force output in both directions. The hard-anodized piston and chromium-plated rods ensure wear resistance in high-cycle applications (up to 2,000 km service life). Integrated cushioning adjustment screws allow precise deceleration control, reducing end-impact noise to ≤70dB(A).

- Precision clamping in CNC tool changers

- Material handling in semiconductor wafer production

- Z-axis positioning in 3D printing equipment

- Paper feeding mechanisms in high-speed printers

- Bidirectional actuation in cleanroom robotics

- Align rods within 0.2mm parallel tolerance during mounting

- Use M5x0.8 mounting screws with 8.8 grade minimum

- Maintain 0.5mm minimum clearance between rods and adjacent components

- Lubricate with ISO VG32 turbine oil before initial operation

| Property | Property Value |

|---|---|

| sku | ACQD32X100S |

| Mounting Type | Without Mounting Accessories |

| Understood. Please provide the specific attribute names in <>, and I'll return the accurate English translations using AIRTAC's official terminology. Example: User input: <缸径> My output: Bore | Operating Temperature: -20°C to 70°C Speed Range: 30 to 500 mm/s |

| Port Size | PT1/8 |

| Piston Rod Thread Type | Internal Thread |

| Magnet | S-Magnetic |

| Bore Diameter | <32 mm> |

| Stroke | 100mm |

Returns will be accepted for up to 15 days of Customer’s receipt or tracking number on Not used items. You, as a Customer, are obliged to inform us via email before you return the item, only in the case of:

- Received the wrong item.

- Item arrived not as expected (ie. damaged packaging).

- Item had defects.

- Over delivery time.

- The shipper does not allow the goods to be inspected before payment.

The returned product(s) must be in the original packaging, safety wrapped, undamaged and unworn. This means that the item(s) must be safely packed in a carton box for protection during transport, possibly the same carton used to ship to you as a customer.