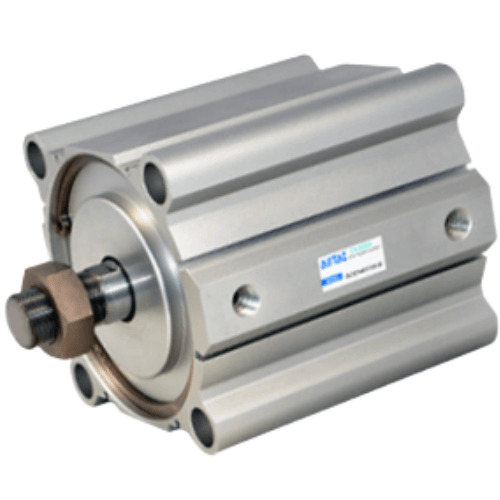

2. Features C-shaped retaining rings for cylinder body and end cover fixation, ensuring compact and reliable construction;

3. Precision-machined bore with hard anodized treatment for superior wear resistance and extended service life;

4. Special-shaped bidirectional sealing structure on piston provides compact dimensions with integrated oil reservoir functionality;

5. Space-saving design effectively minimizes installation footprint;

6. Pre-machined sensor grooves along cylinder periphery facilitate easy sensor mounting.

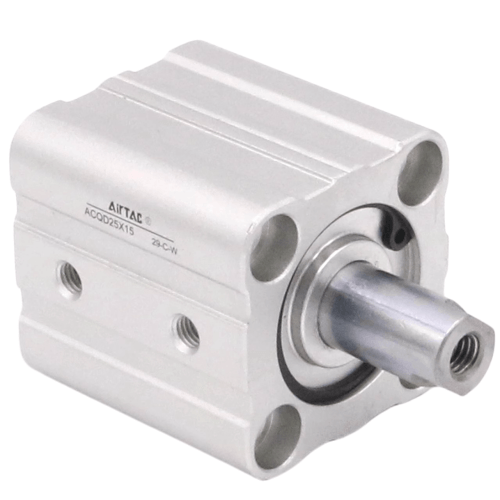

Category: Double Rod Cylinders, Brand: AIRTAC, Series: ACQD125

AirTAC ACQD125X40S Double Rod Thin Cylinder Specifications

- Model: ACQD125X40S

- Type: Compact double-acting cylinder with double rod

- Bore size: 125mm

- Stroke: 40mm (standard) ±0.5mm tolerance

- Operating pressure: 0.05–1.0 MPa

- Cushion type: Adjustable rubber buffer (both ends)

- Temperature range: -20℃ to 80℃

- Port size: G1/2 (ISO228/1 standard)

- Mounting style: Basic fixed mounting (MF1)

- Material:

- Cylinder tube: Aluminum alloy (hard anodized)

- Piston rod: Chrome-plated steel (SUS304 equivalent)

- Seals: NBR (nitrile rubber)

- Weight: 3.8kg ±2% (excluding accessories)

- Dimensions:

- Length: 250mm (minimum retracted length)

- Width: 145mm (max flange dimension)

- Height: 134mm (including mounting brackets)

- Rod diameter: 25mm (both rods)

- Max theoretical force: 1533N @ 0.63MPa

- ISO standard: 15552 compliant

Ultra-slim profile cylinder (32% thinner than standard models) designed for space-constrained linear motion applications. Features synchronized dual-rod movement for balanced force distribution and precise positioning. Anti-rotation design maintains rod alignment during high-speed operations (max 1.0m/s). Includes magnetic piston for sensor compatibility.

- High-density automation cells in electronics assembly

- Vertical lifting mechanisms in packaging machinery

- Precision clamping fixtures for CNC tooling

- Material handling robots in cleanroom environments

- Printing press paper feed systems

| Property | Property Value |

|---|---|

| sku | ACQD125X40S |

| Understood. Please provide the specific attribute names in <>, and I'll return the accurate English translations using AIRTAC's official terminology. Example: User input: <缸径> My output: Bore | Operating Temperature: -20°C to 70°C Speed Range: 30 to 500 mm/s |

| Port Size | PT3/8 |

| Piston Rod Thread Type | Internal Thread |

| Magnet | S-Magnetic |

| Cushion Type | Bumper Pad |

| Bore Diameter | 125mm |

| Stroke | <40mm> |

Returns will be accepted for up to 15 days of Customer’s receipt or tracking number on Not used items. You, as a Customer, are obliged to inform us via email before you return the item, only in the case of:

- Received the wrong item.

- Item arrived not as expected (ie. damaged packaging).

- Item had defects.

- Over delivery time.

- The shipper does not allow the goods to be inspected before payment.

The returned product(s) must be in the original packaging, safety wrapped, undamaged and unworn. This means that the item(s) must be safely packed in a carton box for protection during transport, possibly the same carton used to ship to you as a customer.