1. Complies with JIS standards;

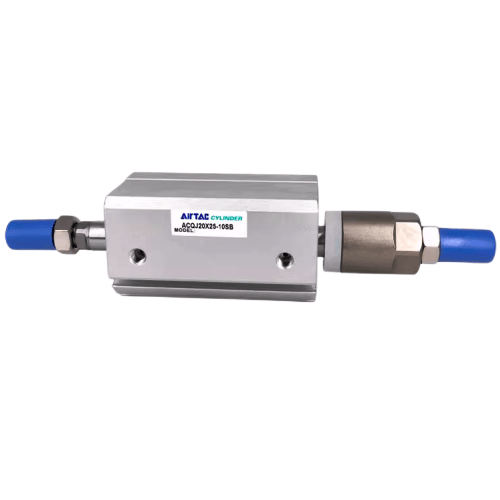

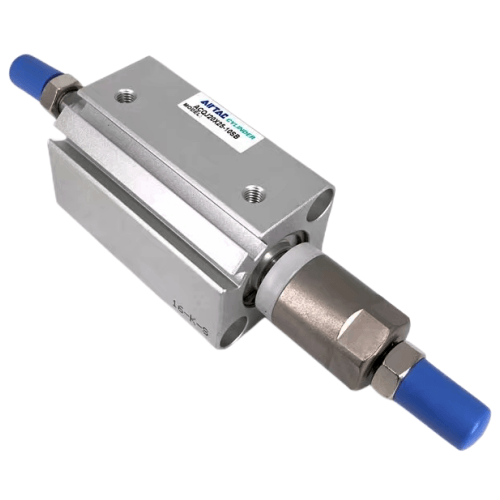

2. C-shaped retaining ring secures cylinder body to front/rear covers, with riveted piston-rod connection for compact and reliable construction;

3. Precision-honed inner bore ensures superior wear resistance and long-term durability;

4. Extended front cover guide length enhances directional stability;

5. Space-saving profile minimizes installation footprint;

6. Perimeter sensor slots enable effortless sensor integration;

7. Multiple mounting accessory configurations available.

Category: Compact Cylinder | Brand: AIRTAC | Series: ACQJ50~63

AirTAC ACQJ63X75-10 Adjustable Compact Cylinder Specifications

- Series: ACQJ50~63 Slim Cylinder Line

- Model: ACQJ63X75-10

- Bore size: 63mm (ISO 21287 compliant)

- Stroke: 75mm (±0.5mm tolerance)

- Adjustable cushioning: Dual-side air cushion with 3-stage adjustment

- Operating pressure: 0.05~1.0 MPa

- Ambient temperature: -10℃ to 70℃ (NBR seals)/-20℃ to 70℃ (FKM seals optional)

- Piston speed: 50~800 mm/s (optimized for precision applications)

- Port size: M5x0.8 (G1/8 adaptor included)

- Mounting style: Basic type (ISO 15552 foot mounting compatible)

- Rod end: Female thread M16x1.5 (standard), male thread optional

- Cylinder tube: Hard anodized aluminum alloy

- Piston rod: Chrome-plated steel (S45C)

- Weight: 1.68kg (without accessories)

- Dimensions:

- Length: 167mm (min. folded length)

- Width: 82mm (mounting flange to rod end)

- Height: 63mm (cylinder diameter)

- ISO 8573-1 air quality requirement: Class 3.4.3 (lubricated or non-lubricated)

Ultra-slim profile cylinder with precision-adjustable cushioning, featuring 20% reduced installation height compared to standard ISO cylinders. The double O-ring piston seal ensures ≤0.5mm/s creep speed at 0.3MPa. Integrated magnet slot (T-slot design) for sensor mounting compatibility. Optional auto switch models available (Hall effect/reed type).

- PCB handling robots requiring precise end-position control

- Vertical lift mechanisms in semiconductor wafer production

- Clamping fixtures for CNC machine tooling

- High-cycle packaging line pusher mechanisms (up to 1.2 million cycles/year)

- Cleanroom-compatible material handling systems

| Property | Property Value |

|---|---|

| sku | ACQJ63X75-10 |

| Adjustable Stroke | <10mm> |

| Mounting Type | Without Mounting Accessories |

| Understood. Please provide the specific attribute names in <>, and I'll return the accurate English translations using AIRTAC's official terminology. Example: User input: <缸径> My output: Bore | Operating Temperature: -20°C to 70°C Speed Range: 30 to 500 mm/s |

| Port Size | PT1/4 |

| Magnet | Non-magnetic |

| Bore Diameter | 63mm |

| Stroke | 75mm |

Returns will be accepted for up to 15 days of Customer’s receipt or tracking number on Not used items. You, as a Customer, are obliged to inform us via email before you return the item, only in the case of:

- Received the wrong item.

- Item arrived not as expected (ie. damaged packaging).

- Item had defects.

- Over delivery time.

- The shipper does not allow the goods to be inspected before payment.

The returned product(s) must be in the original packaging, safety wrapped, undamaged and unworn. This means that the item(s) must be safely packed in a carton box for protection during transport, possibly the same carton used to ship to you as a customer.