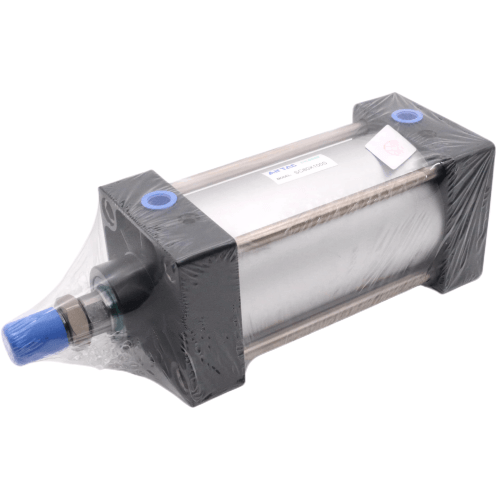

AirTAC B04-SC Construction Machinery Standard Cylinder B04-SC100X225S Specifications

- Model Code Breakdown: B04(Series)-SC(Construction Special)-100(Bore Φ100mm)-225(Stroke 225mm)-S(Magnetic Switch)

- Bore Size: 100 mm (ISO 6432 standard)

- Stroke: 225 mm (±1.5mm tolerance)

- Operating Pressure: 0.1-0.9 MPa (1-9 bar)

- Cushion Type: Adjustable buffer at both ends

- Mounting Style: Basic type (Standard MF1 front flange & triangle rear)

- Port Size: G1/2 (ISO 228-1)

- Piston Speed: 50-750 mm/s (optimal range 150-500 mm/s)

- Ambient Temperature: -20℃ to +80℃ (NBR seals)

- Lubrication: Pre-lubricated (Non-re-lube design)

- Repeat Accuracy: ±0.5 mm

- Material:

- Tube: Hard anodized aluminum alloy

- Piston Rod: Chrome-plated steel (Cr equivalent ≥0.8μm)

- End Caps: Cast aluminum (ADC12)

- Weight: 5.8 kg (including standard mounting accessories)

- Dimensions:

- Total Length: 403 mm (stroke 225 + 178mm base length)

- Width: 112 mm (flange mounting surface)

- Height: 128 mm (including rod end)

- IP Rating: IP65 (wipers included)

- Certifications: ISO 6432, GB/T 2348-2018

Heavy-duty pneumatic cylinder engineered for construction equipment applications, featuring enhanced structural rigidity and dust-resistant construction. The double-acting design incorporates chrome-plated piston rods with multi-layered seal reinforcement, capable of withstanding continuous impact loads up to 1.5× rated pressure. Integrated cushioning adjustment screws allow precise deceleration control for heavy loads.

- Excavator bucket linkage control systems

- Concrete pump truck outrigger positioning

- Loader implement quick-coupler actuation

- Crane boom angle adjustment mechanisms

- Pile driver hammer impact control

| Property | Property Value |

|---|---|

| sku | B04-SC100X225S |

Returns will be accepted for up to 15 days of Customer’s receipt or tracking number on Not used items. You, as a Customer, are obliged to inform us via email before you return the item, only in the case of:

- Received the wrong item.

- Item arrived not as expected (ie. damaged packaging).

- Item had defects.

- Over delivery time.

- The shipper does not allow the goods to be inspected before payment.

The returned product(s) must be in the original packaging, safety wrapped, undamaged and unworn. This means that the item(s) must be safely packed in a carton box for protection during transport, possibly the same carton used to ship to you as a customer.