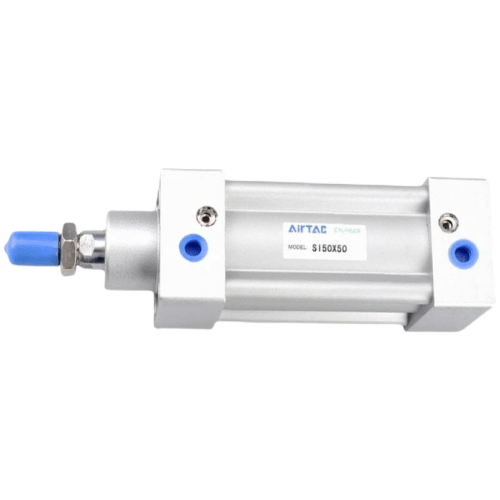

AirTAC B04-SI32X250S Construction Machinery ISO Cylinder Specifications

- Model: B04-SI32X250S

- Series: B04-SI (Construction Machinery Special)

- Standard: ISO 15552 (VDI 2453 compliant)

- Bore size: 32mm (1-1/4")

- Stroke: 250mm (adjustable cushioning ±5mm)

- Operating pressure: 0.15-1.0 MPa (21.7-145 PSI)

- Piston speed: 50-750 mm/s (lubricated)

- Ambient temperature: -20℃ to 80℃ (-4°F to 176°F)

- Port size: G1/8 (ISO 1179-1 standard)

- Cushioning: Adjustable rubber buffer (both ends)

- Seal material: NBR standard (Polyurethane optional)

- Rod material: Hard chrome-plated steel (HCP)

- Tube material: Anodized aluminum alloy

- Mounting: Basic front flange (ISO 15552-AF50)

- Weight: 2.46 kg (5.42 lbs)

- Dimensions: 350mm(L) × 40mm(W) × 40mm(H) (body only)

- Extended length: 598mm (with rod at full stroke)

- Protection rating: IP65 (standard wiper design)

Heavy-duty pneumatic cylinder engineered for construction equipment applications. Features enhanced structural integrity with 20% thicker tube walls compared to standard ISO cylinders, capable of withstanding shock loads up to 1.5x rated pressure. Includes anti-rotation guide slots and reinforced rod bearings for lateral force resistance. Requires ISO VG32 hydraulic oil lubrication when used in high-cycle applications (>500,000 cycles/year).

- Excavator bucket locking mechanisms

- Concrete pump truck valve actuators

- Crane outrigger position locks

- Drilling rig feed control systems

- Loader arm positioning cylinders

- Relubricate every 500km of cumulative rod movement

- Replace wiper seals every 2 million cycles

- Inspect rod concentricity quarterly in high-vibration environments

| Property | Property Value |

|---|---|

| sku | B04-SI32X250S |

Returns will be accepted for up to 15 days of Customer’s receipt or tracking number on Not used items. You, as a Customer, are obliged to inform us via email before you return the item, only in the case of:

- Received the wrong item.

- Item arrived not as expected (ie. damaged packaging).

- Item had defects.

- Over delivery time.

- The shipper does not allow the goods to be inspected before payment.

The returned product(s) must be in the original packaging, safety wrapped, undamaged and unworn. This means that the item(s) must be safely packed in a carton box for protection during transport, possibly the same carton used to ship to you as a customer.