2. Enables positive locking at any intermediate position during stroke travel;

3. Precision-engineered locking system ensures engagement stability independent of piston movement direction.

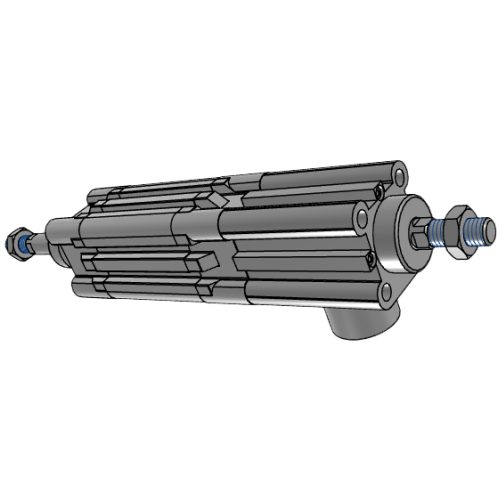

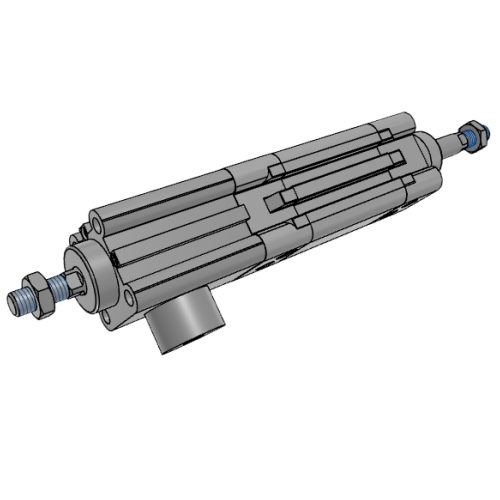

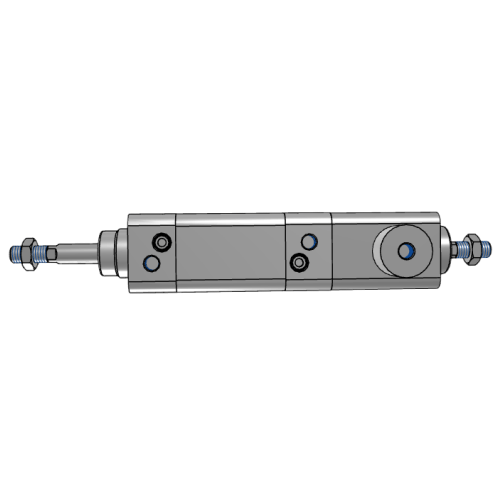

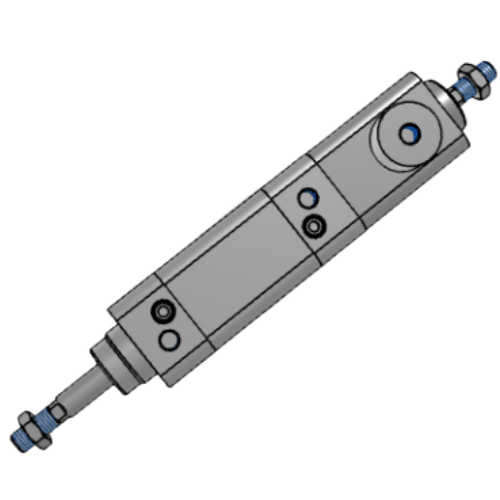

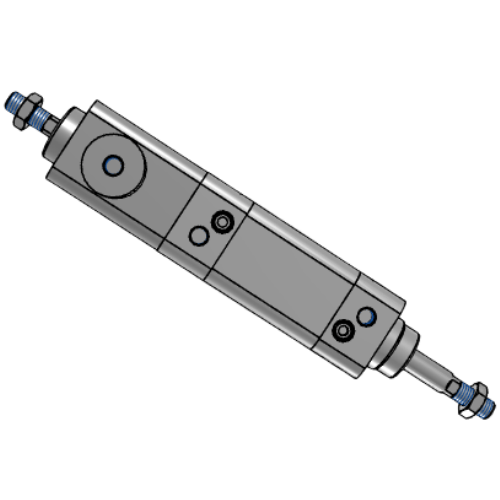

Category: Double-acting cylinders, Brand: AirTAC, Series: BSED

AirTAC BSED40X900S Clamping Double Rod Cylinder Specifications

- Model: BSED40X900S

- Type: Double-acting clamping cylinder with dual piston rods

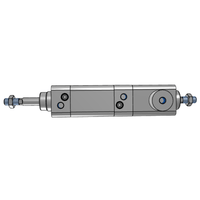

- Bore size: 40mm

- Stroke: 900mm

- Operating pressure: 0.05–1.0 MPa

- Port size: G1/8 (ISO standard)

- Cushioning type: Adjustable pneumatic cushion (both ends)

- Mounting style: Fixed type with integrated clamping mechanism

- Temperature range: -20℃ to 80℃

- Body material: Aluminum alloy (anodized)

- Rod material: Stainless steel (SUS304)

- Seal material: NBR/PU compound seals

- Protection rating: IP40 (standard), optional IP67

- Weight: ~5.8 kg (excluding accessories)

- Dimensions: 950mm(L) × 80mm(W) × 80mm(H) (extended length)

- Retracted length: 580mm

- Maximum lateral load: 220N

- Clamping force: 1,960N @ 0.5MPa

High-rigidity double rod cylinder featuring synchronized clamping action through dual piston rods. Engineered for precision positioning and heavy-duty applications requiring simultaneous bilateral force. The integrated clamping mechanism provides immediate locking upon reaching target position, with 0.5° angular tolerance for precision alignment. Features wear-resistant rod guides and anti-rotation design for stable operation in high-moment scenarios.

- Automated fixture systems for CNC machining centers

- Press brake tool clamping in metal fabrication

- Pallet locking in robotic workcells

- Elevated load handling in warehouse automation

- Precision mold positioning in injection molding

- Max speed: 500mm/s (with cushioning engaged)

- Repeat positioning accuracy: ±0.1mm

- Minimum holding pressure: 0.3MPa

- Lubrication: Pre-lubricated (Relubrication interval: 2 million cycles)

| Property | Property Value |

|---|---|

| sku | BSED40X900S |

| Understood. Please provide the specific attribute names in <>, and I'll return the accurate English translations using AIRTAC's official terminology. Example: User input: <缸径> My output: Bore | Operating Temperature:-20-70°C Speed Range:30-800mm/s |

| Port Size | PT1/4 |

| Magnet | S-Magnetic |

| Cushion Stroke | 27mm |

| Bore Diameter | <40mm> |

| Stroke | <900mm> |

| Static Holding Force | 900N |

Returns will be accepted for up to 15 days of Customer’s receipt or tracking number on Not used items. You, as a Customer, are obliged to inform us via email before you return the item, only in the case of:

- Received the wrong item.

- Item arrived not as expected (ie. damaged packaging).

- Item had defects.

- Over delivery time.

- The shipper does not allow the goods to be inspected before payment.

The returned product(s) must be in the original packaging, safety wrapped, undamaged and unworn. This means that the item(s) must be safely packed in a carton box for protection during transport, possibly the same carton used to ship to you as a customer.