2. Enables positive locking at any intermediate position during stroke travel;

3. Precision-engineered locking system ensures engagement stability independent of piston movement direction.

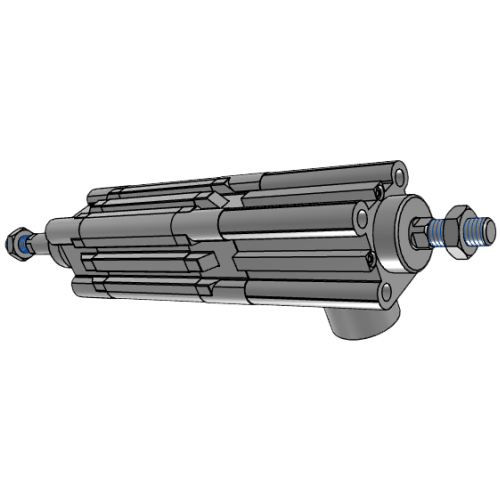

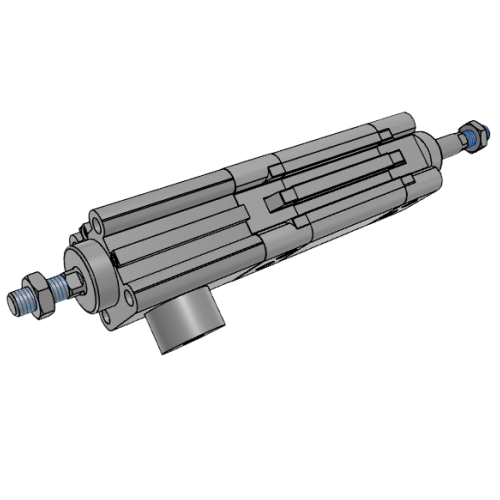

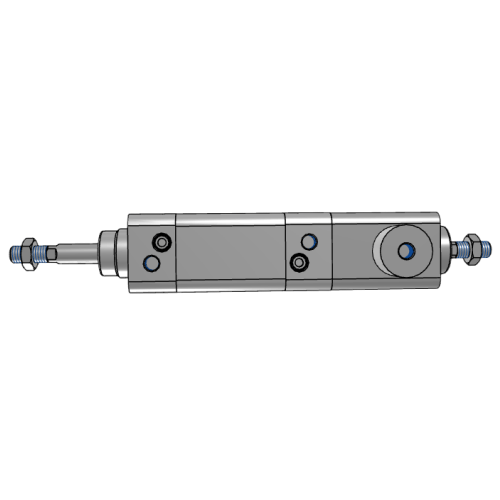

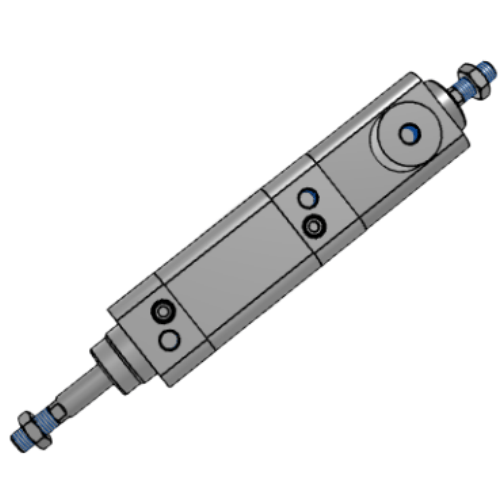

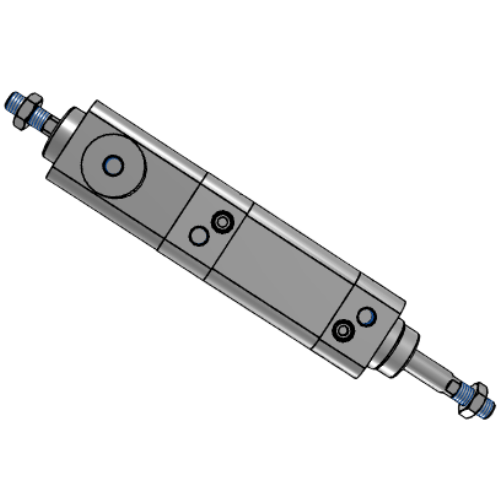

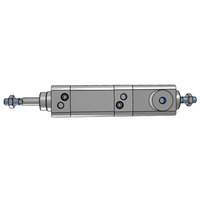

Category: Double-acting cylinders, Brand: AirTAC, Series: BSED

AirTAC BSED50X1000S Clamping Double-Output Cylinder Specifications

- Model: BSED50X1000S

- Type: Double-rod clamping cylinder (ISO 6432 compliant)

- Bore size: Ø50 mm

- Stroke: 1000 mm (customizable 50-2000mm)

- Operating pressure: 0.1-0.9 MPa

- Cushioning: Adjustable pneumatic cushion both ends

- Mounting types: MF1/MF2 front flange, MB1/MB2 rear flange, MP4 foot mounting

- Port size: G1/8 (NPT1/4 optional)

- Piston rod material: Hard chrome-plated SUS304

- Cylinder tube: Aluminum alloy with hard anodized surface

- Seal material: NBR (HNBR optional for high temp)

- Temperature range: -20℃ to 80℃ (extended to 150℃ with HNBR seals)

- Weight: 18.6 kg ±2% (without accessories)

- Dimensions: 1100mm(L) × 78mm(W) × 78mm(H) (stroke-dependent length)

- Sensor compatibility: Built-in magnet for PU series magnetic switches

- Lubrication: Pre-lubricated (Use ISO VG32 turbine oil if needed)

High-rigidity clamping cylinder with dual piston rods for synchronized bidirectional force transmission. Features anti-rotation mechanism for precision alignment in long-stroke applications. The chrome-plated piston rods and integrated scraper design prevent particulate ingress in harsh environments.

- Automotive welding fixture clamping systems

- Press machine die positioning

- Large-format CNC router material hold-down

- Glass manufacturing conveyor synchronization

- Battery module assembly presses

1. Ensure 0.3mm minimum clearance between rods during alignment

2. Use locknuts with 35-45 N·m torque for flange mounting

3. Install rod supports every 500mm stroke for >800mm applications

4. Maintain 1-3% lubricator oil concentration in air supply

| Property | Property Value |

|---|---|

| sku | BSED50X1000S |

| Understood. Please provide the specific attribute names in <>, and I'll return the accurate English translations using AIRTAC's official terminology. Example: User input: <缸径> My output: Bore | Operating Temperature:-20-70°C Speed Range:30-800mm/s |

| Port Size | PT1/4 |

| Magnet | S-Magnetic |

| Cushion Stroke | 30mm |

| Bore Diameter | <50mm> |

| Stroke | <1000mm> |

| Static Holding Force | 1400N |

Returns will be accepted for up to 15 days of Customer’s receipt or tracking number on Not used items. You, as a Customer, are obliged to inform us via email before you return the item, only in the case of:

- Received the wrong item.

- Item arrived not as expected (ie. damaged packaging).

- Item had defects.

- Over delivery time.

- The shipper does not allow the goods to be inspected before payment.

The returned product(s) must be in the original packaging, safety wrapped, undamaged and unworn. This means that the item(s) must be safely packed in a carton box for protection during transport, possibly the same carton used to ship to you as a customer.