2. Enables positive locking at any intermediate position during stroke travel;

3. Precision-engineered locking system ensures engagement stability independent of piston movement direction.

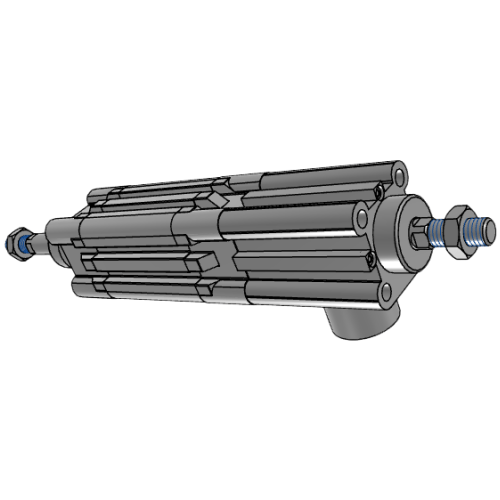

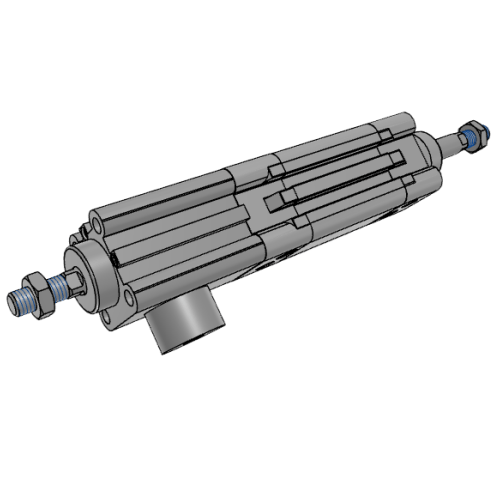

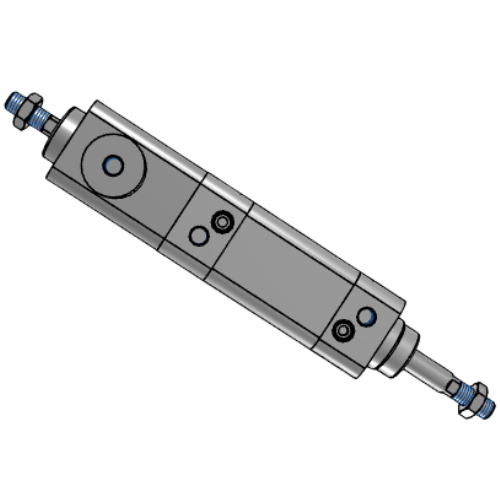

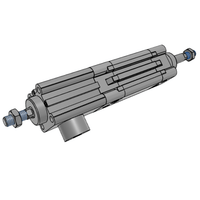

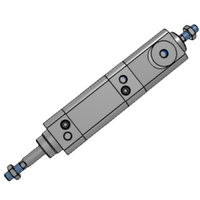

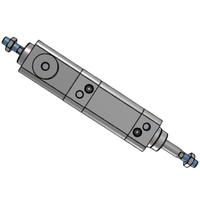

Category: Double-acting cylinders, Brand: AirTAC, Series: BSED

AirTAC BSED Series Clamping Double Rod Cylinder BSED80X100 Specifications

- Model: BSED80X100

- Type: Double rod clamping cylinder (ISO 15552 standard)

- Bore size: 80 mm

- Stroke: 100 mm

- Operating pressure: 0.15–0.9 MPa

- Operating temperature: -20℃ to 80℃

- Cushioning type: Adjustable pneumatic cushion (both ends)

- Port size: G1/2 (ISO 228/1 standard)

- Piston rod thread: M20×1.5 (both ends)

- Mounting style: Fixed mounting (MF1) with front flange

- Material:

- Tube: Aluminum alloy (hard anodized)

- Piston rod: Chrome-plated steel

- Seals: NBR + PU combination

- Protection rating: IP65 (standard wiper seal)

- Weight: 4.3 kg (±2%)

- Dimensions:

- Length (retracted): 260 mm

- Body diameter: 95 mm

- Stroke tolerance: +1.5 mm

- Mounting hole spacing: 140×140 mm

High-rigidity clamping cylinder featuring dual piston rods with mechanical locking mechanism. The integrated wedge clamping system provides 2.5× higher holding force compared to standard cylinders. Precision ground rods with multi-lip seal design ensure zero leakage during clamping operations. Includes magnetic piston for position sensing compatibility.

- Fixture locking in CNC machining centers

- Press-fit assembly of automotive components

- Pallet clamping in automated warehouses

- Mold securing in injection molding machines

- Workpiece positioning in robotic welding cells

| Property | Property Value |

|---|---|

| sku | BSED80X100 |

| Understood. Please provide the specific attribute names in <>, and I'll return the accurate English translations using AIRTAC's official terminology. Example: User input: <缸径> My output: Bore | Operating Temperature:-20-70°C Speed Range:30-800mm/s |

| Port Size | PT3/8 |

| Magnet | Non-magnetic |

| Cushion Stroke | 30mm |

| Bore Diameter | 80 mm |

| Stroke | 100mm |

| Static Holding Force | 3600 N |

Returns will be accepted for up to 15 days of Customer’s receipt or tracking number on Not used items. You, as a Customer, are obliged to inform us via email before you return the item, only in the case of:

- Received the wrong item.

- Item arrived not as expected (ie. damaged packaging).

- Item had defects.

- Over delivery time.

- The shipper does not allow the goods to be inspected before payment.

The returned product(s) must be in the original packaging, safety wrapped, undamaged and unworn. This means that the item(s) must be safely packed in a carton box for protection during transport, possibly the same carton used to ship to you as a customer.