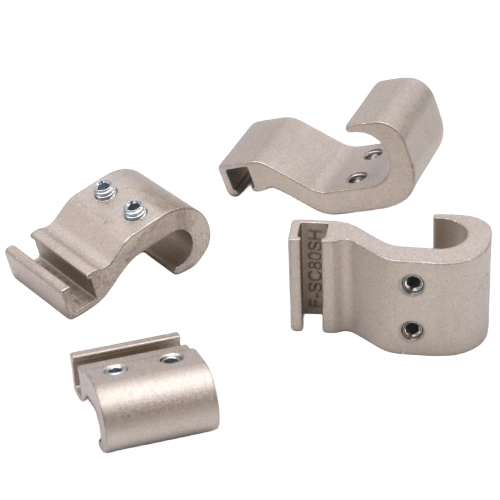

AirTAC F-SI-H Series Sensor Bracket Kit F-SI32H Technical Details

- Model: F-SI32H (Complete Kit)

- Compatible Sensor Type: M8/M12 inductive/capacitive proximity sensors

- Material: Anodized aluminum alloy (black finish)

- Mounting Style: Horizontal/vertical dual-orientation slots

- Thread Size: M8×1.25 mounting screw included

- Clamping Force: 15-20N·m torque range (with lock washer)

- Surface Hardness: HV400-450 (Vickers scale)

- Temperature Resistance: -25℃ to +85℃

- Vibration Resistance: 10-55Hz, 1.5mm amplitude

- IP Rating: IP67 (dust/water protected)

- Weight: 78g ±2g (including hardware)

- Dimensions: 42mm(L) × 32mm(W) × 18mm(H)

- Package Contents: Bracket body, M4×16 stainless steel screws (2pcs), anti-vibration shims

Robust modular mounting solution designed for precision sensor alignment in harsh industrial environments. Features laser-etched positioning marks (±5° adjustment scale) and tool-less micro-adjustment capability (0.8mm lateral fine-tuning). The zinc-nickel plated hardware resists chemical corrosion in washdown areas.

- AGV collision avoidance system sensor mounting

- CNC machine tool position verification setups

- Food processing conveyor belt object detection

- Robotic welding arm end-effector alignment

- Pharmaceutical packaging line quality control stations

| Property | Property Value |

|---|---|

| sku | F-SI32H |

Returns will be accepted for up to 15 days of Customer’s receipt or tracking number on Not used items. You, as a Customer, are obliged to inform us via email before you return the item, only in the case of:

- Received the wrong item.

- Item arrived not as expected (ie. damaged packaging).

- Item had defects.

- Over delivery time.

- The shipper does not allow the goods to be inspected before payment.

The returned product(s) must be in the original packaging, safety wrapped, undamaged and unworn. This means that the item(s) must be safely packed in a carton box for protection during transport, possibly the same carton used to ship to you as a customer.