2. Features profiled bidirectional sealing structure with compact dimensions and integrated oil reservoir for piston lubrication;

3. JSI Series utilizes cross-braced aluminum alloy tubing with tie-rod-free design, offering superior corrosion resistance;

4. Reduced overall length compared to ISO15552 standard cylinders of equivalent bore size;

5. Precision-adjustable pneumatic cushioning mechanism ensures smooth deceleration;

6. Comprehensive selection of bore sizes and mounting accessories available for customized system integration.

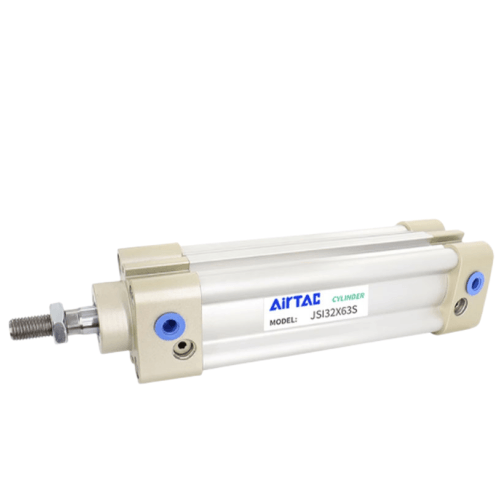

Category: Standard Cylinders, Brand: AirTAC, Series: JSI

AirTAC JSI Standard Cylinder JSI100X200FA Technical Specifications

- Complete model designation: JSI100X200FA-

(Customizable suffix codes available) - Bore diameter: Ø100mm (3.94") ±0.02mm manufacturing tolerance

- Stroke length: 200mm (7.87") ±1mm positional accuracy

- Working pressure range: 0.1-0.9 MPa (14.5-130.5 PSI)

- Buffer configuration: 5-stage adjustable pneumatic cushion with progressive damping

- Installation method: Front flange mount (ISO 15552 compliant)

- Connection ports: G3/8 (BSPP) or 1/2 NPT selectable

- Piston rod threading: M20×1.5 external thread (18mm protrusion length)

- Operating temperature: -20℃ to 80℃ (-4°F to 176°F)

- Barrel composition: AL6063-T5 aluminum alloy with hard anodized surface

- Rod material: S45C chromium-plated steel (HRC 40-50 hardness rating)

- Sealing system: NBR+PU hybrid seals (FDA-certified variants optional)

- Unit weight: 5.8kg (12.8lbs) ±3% (bare cylinder measurement)

- Dimensional specs: 400mm(L) × 110mm(W) × 110mm(H) (15.75"×4.33"×4.33")

- Ingress protection: IP65 (standard), IP67 upgrade available

- Force output: 706N @0.6MPa (extension), 635N @0.6MPa (retraction)

- Speed capacity: 500-800mm/s (with cushioning optimization)

Precision-engineered ISO cylinder featuring dual anti-rotation guides, enhanced with wear-resistant chromium carbide rod coating and embedded magnetic field for position detection. The triple-lip sealing architecture guarantees 5+ million cycles of maintenance-free performance. Requires compressed air meeting ISO 8573-1:2010 Class 3 standards (maximum 50mg/m³ oil content).

- Robotic welding clamp actuation in automotive assembly

- Ejection systems for high-tonnage injection molding presses

- Coil transfer mechanisms in steel rolling operations

- High-speed paper processing/converting machinery

- Sanitary vertical elevators in food packaging lines (stainless steel variant)

| Property | Property Value |

|---|---|

| sku | JSI100X200FA |

| Understood. Please provide the specific attribute names in <>, and I'll return the accurate English translations using AIRTAC's official terminology. Example: User input: <缸径> My output: Bore | Operating Temperature:-20-70°C Speed Range:30-800mm/s |

| Port Size | PT 1/2 |

| Magnet | Non-magnetic |

| Cushion Stroke | 29mm |

| Bore Diameter | 100mm |

| Stroke | <200mm> |

Returns will be accepted for up to 15 days of Customer’s receipt or tracking number on Not used items. You, as a Customer, are obliged to inform us via email before you return the item, only in the case of:

- Received the wrong item.

- Item arrived not as expected (ie. damaged packaging).

- Item had defects.

- Over delivery time.

- The shipper does not allow the goods to be inspected before payment.

The returned product(s) must be in the original packaging, safety wrapped, undamaged and unworn. This means that the item(s) must be safely packed in a carton box for protection during transport, possibly the same carton used to ship to you as a customer.