Description

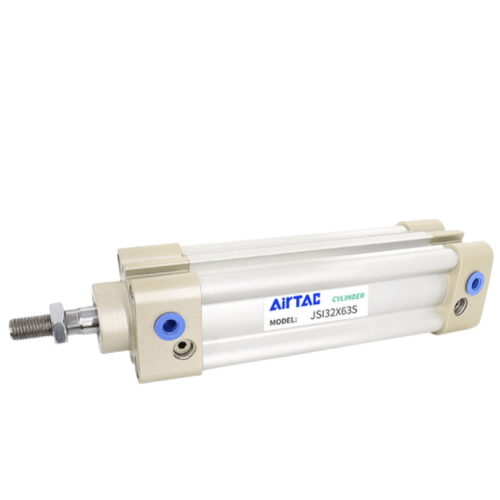

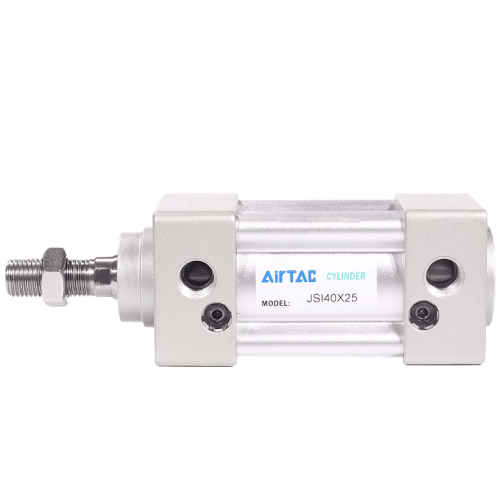

1. JIS-compliant triple-seal cylinder;

2. Features profiled bidirectional sealing structure with compact dimensions and integrated oil reservoir for piston lubrication;

3. JSI Series utilizes cross-braced aluminum alloy tubing with tie-rod-free design, offering superior corrosion resistance;

4. Reduced overall length compared to ISO15552 standard cylinders of equivalent bore size;

5. Precision-adjustable pneumatic cushioning mechanism ensures smooth deceleration;

6. Comprehensive selection of bore sizes and mounting accessories available for customized system integration.

Category: Standard Cylinders, Brand: AirTAC, Series: JSI

Installation note:

Align cylinder axis within 0.2mm angular misalignment. Use flexible couplings for

stroke-end impact reduction. Lubricate through air supply (1-2 drops/m³).

Installation note:

Align cylinder axis within 0.2mm angular misalignment. Use flexible couplings for

stroke-end impact reduction. Lubricate through air supply (1-2 drops/m³).

2. Features profiled bidirectional sealing structure with compact dimensions and integrated oil reservoir for piston lubrication;

3. JSI Series utilizes cross-braced aluminum alloy tubing with tie-rod-free design, offering superior corrosion resistance;

4. Reduced overall length compared to ISO15552 standard cylinders of equivalent bore size;

5. Precision-adjustable pneumatic cushioning mechanism ensures smooth deceleration;

6. Comprehensive selection of bore sizes and mounting accessories available for customized system integration.

Category: Standard Cylinders, Brand: AirTAC, Series: JSI

AirTAC JSI125X130S Standard Cylinder Specifications

- Model: JSI125X130S

- Type: Single rod double-acting ISO cylinder

- Bore size: Ø125mm

- Stroke: 130mm (customizable 25-1000mm)

- Operating pressure: 0.1–0.9 MPa

- Cushion type: Adjustable air cushion (both ends)

- Port size: G1/2 (NPT1/2 optional)

- Operating temperature: -20℃ to 80℃

- Seal material: NBR (HNBR optional for high temp)

- Piston speed: 50–750 mm/s

- Mounting types: Basic/Foot/Flange (MF1/MF2)

- Rod rotation: Anti-rotation design

- Weight: 6.8 kg (bare cylinder)

- Dimensions: 300mm(L) × 140mm(W) × 140mm(H)

High-force industrial cylinder with chromed piston rod and anodized aluminum barrel. Features dual magnetic switches (sensor slots) and corrosion-resistant construction. Designed for heavy-duty cycles (5 million strokes@0.5MPa). Requires filtered air (≤40μm) with ISO VG32 lubricator.

Typical Applications:

- Press machine ejection systems

- Automotive welding fixture clamping

- Steel mill conveyor stoppers

- Plastic injection molding machines

- Palletizing robot end effectors

Caution:

Do NOT exceed 1.0MPa pressure. Install locking nuts when using flange mounts

under vibration conditions. Allow 50mm clearance for magnetic sensor adjustment.

| Property | Property Value |

|---|---|

| sku | JSI125X130S |

| Understood. Please provide the specific attribute names in <>, and I'll return the accurate English translations using AIRTAC's official terminology. Example: User input: <缸径> My output: Bore | Operating Temperature:-20-70°C Speed Range:30-800mm/s |

| Port Size | PT 1/2 |

| Magnet | S-Magnetic |

| Cushion Stroke | 33mm |

| Bore Diameter | 125mm |

| Stroke | 130mm |

Shipping policies

Returns will be accepted for up to 15 days of Customer’s receipt or tracking number on Not used items. You, as a Customer, are obliged to inform us via email before you return the item, only in the case of:

- Received the wrong item.

- Item arrived not as expected (ie. damaged packaging).

- Item had defects.

- Over delivery time.

- The shipper does not allow the goods to be inspected before payment.

The returned product(s) must be in the original packaging, safety wrapped, undamaged and unworn. This means that the item(s) must be safely packed in a carton box for protection during transport, possibly the same carton used to ship to you as a customer.

Reviews

Recently Viewed

Explore your recently viewed items, blending quality and style for a refined living experience.