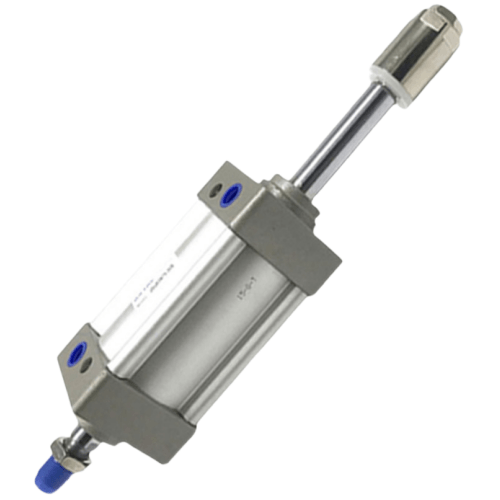

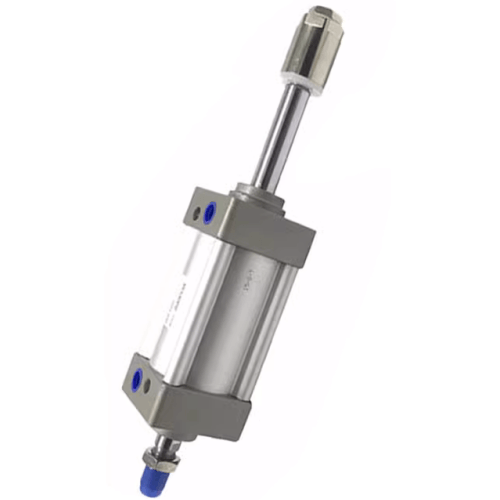

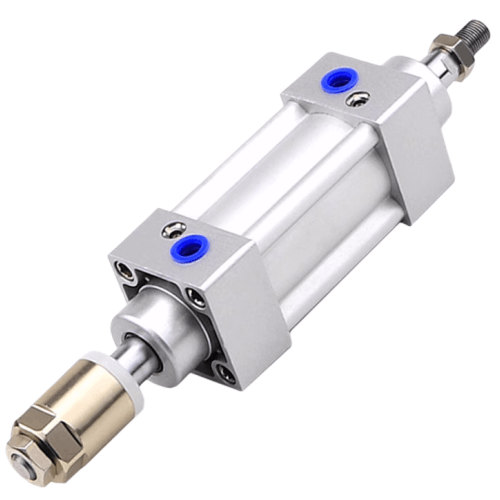

2、Profiled bidirectional sealing structure with integrated oil reservoir for compact piston sealing;

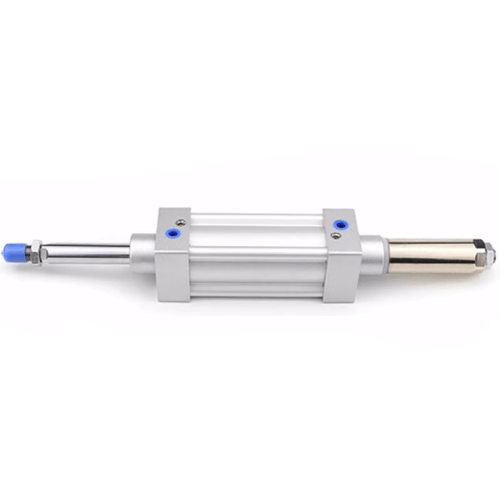

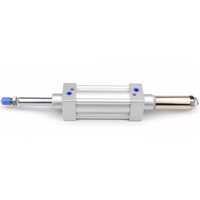

3、Aluminum tube construction with cross-reinforced pattern (tie-rod-free design) for enhanced corrosion resistance;

4、Compact axial dimensions compared to ISO15552 standard cylinders of equivalent bore size;

5、Precision-adjustable cushioning mechanism for smooth stroke termination;

6、Comprehensive product line with multiple specifications and configurable mounting accessories.

Category: Standard Cylinders , Brand: AIRTAC , Series: JSIJ63~80

AirTAC JSIJ63X600-40S Adjustable Stroke Cylinder Specifications

- Series: JSIJ63~80 Adjustable Stroke Cylinder

- Model: JSIJ63X600-40S

- Bore size: 63mm (Standard JIS/ISO 6432 compatible)

- Stroke: 600mm (Adjustable with ±0.5mm precision)

- Adjustment method: External mechanical locking device with hex wrench

- Operating pressure: 0.1–0.8 MPa (14.5–116 PSI)

- Temperature range: -20℃ to 80℃ (-4°F to 176°F)

- Cushioning: Rubber buffer + adjustable air cushion

- Mounting type: Basic MF1 (Standard foot mounting) with optional flange/bracket kits

- Port size: PT1/4 (G1/4 optional)

- Rod end thread: M16×1.5 (ISO 12240-1 standard)

- Material: Aluminum alloy barrel (hard anodized), CR steel piston rod (chrome-plated)

- Seal type: NBR (Nitrile) with wear-resistant ring

- IP rating: IP40 (Dust protected)

- Weight: 6.8kg (14.99 lbs) ±3%

- Dimensions: 780mm(L) × 95mm(W) × 95mm(H) (Extended length)

- Retracted length: 180mm (Minimum installation space)

- Max thrust: 1,080N @ 0.6MPa (Forward stroke)

Heavy-duty adjustable stroke cylinder with precision mechanical locking mechanism, featuring dual cushioning system for smooth operation in long-stroke applications. The chrome-plated piston rod provides enhanced corrosion resistance for humid environments. Requires 5-40μm filtered compressed air with ISO 8573-1:2010 Class 3 air quality.

- Automated palletizing systems with variable box sizes

- Plastic injection molding machine ejectors

- Paper converting equipment with adjustable cutting lengths

- Automotive welding fixture positioning

- Glass handling systems requiring precise placement

- Always lock adjustment screw with 2.5N·m torque after positioning

- Maintain 0.5mm minimum clearance between rod end and load during alignment

- Lubricate with ISO VG32 hydraulic oil if using non-lubricated air systems

| Property | Property Value |

|---|---|

| sku | JSIJ63X600-40S |

| Adjustable Stroke | <40mm> |

| Understood. Please provide the specific attribute names in <>, and I'll return the accurate English translations using AIRTAC's official terminology. Example: User input: <缸径> My output: Bore | Operating Temperature:-20-70°C Speed Range:30-800mm/s |

| Port Size | PT3/8 |

| Magnet | S-Magnetic |

| Cushion Stroke | 20.5mm |

| Bore Diameter | 63mm |

| Stroke | 600mm |

Returns will be accepted for up to 15 days of Customer’s receipt or tracking number on Not used items. You, as a Customer, are obliged to inform us via email before you return the item, only in the case of:

- Received the wrong item.

- Item arrived not as expected (ie. damaged packaging).

- Item had defects.

- Over delivery time.

- The shipper does not allow the goods to be inspected before payment.

The returned product(s) must be in the original packaging, safety wrapped, undamaged and unworn. This means that the item(s) must be safely packed in a carton box for protection during transport, possibly the same carton used to ship to you as a customer.