2、Integrated riveted aluminum cladding structure ensures reliable connection between end caps and alloy barrel;

3、Compact piston design with specialized bidirectional sealing profile incorporating oil reservoir functionality;

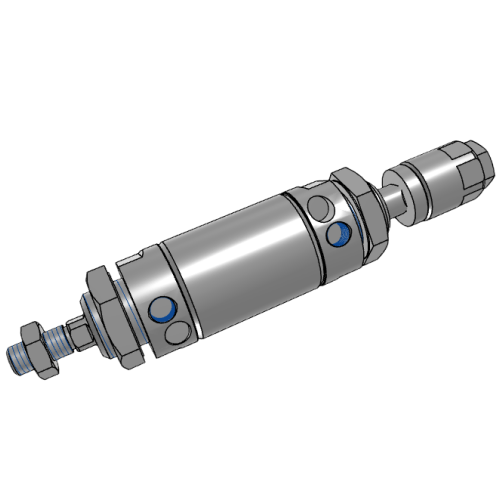

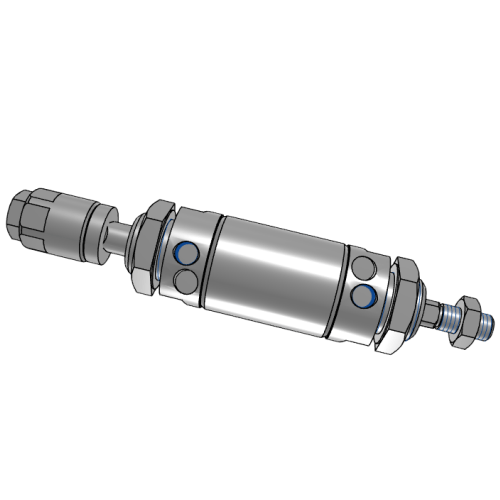

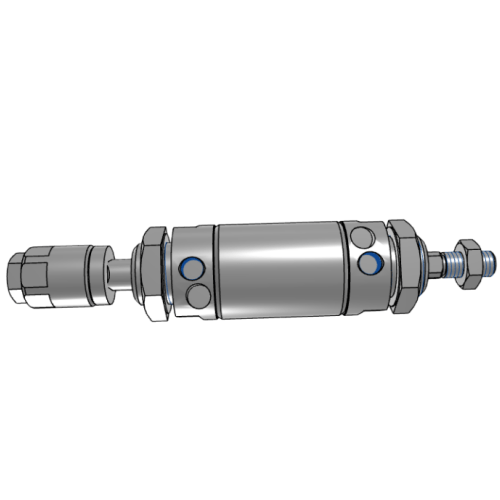

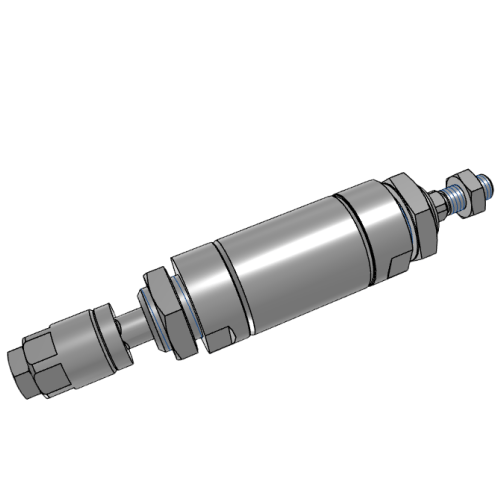

4、Multiple rear cover configurations enhance mounting flexibility;

5、Comprehensive product range with various cylinder sizes and mounting accessories for optimal system integration.

Category: Adjustable Cylinders , Brand: AIRTAC , Series: MBLCJ

AirTAC MBLCJ Adjustable Miniature Cylinder MBLCJ40X250-30 Technical Details

- Model Structure: MBLCJ[40][X250][-30]

- Bore Size: 40mm (ISO 6432 standard)

- Stroke: 250mm (±0.5mm tolerance)

- Adjustable Cushioning: Dual-side rubber buffer with ±5° angle adjustment

- Operating Pressure: 0.05-1.0 MPa (7-145 psi)

- Temperature Range: -20℃ to 80℃ (dry air required below 0℃)

- Piston Speed: 50-750 mm/s (lubricated operation)

- Port Size: M5x0.8 (Standard) / NPT1/8 (Optional)

- Rod Thread: M10x1.25 (External)

- Material:

- Barrel: Hard anodized aluminum alloy

- Piston Rod: Chrome-plated steel (HRC 45-50)

- Seals: HNBR (Hydrogenated Nitrile) for high temperature resistance

- Weight: 1.65kg (with standard accessories)

- Dimensions:

- Extended Length: 416mm (Cushion adjusted to midpoint)

- Retracted Length: 166mm

- Body Width: 56mm (Including mounting lugs)

- Height: 48mm (Square barrel profile)

- ISO Certification: Compliant with ISO 6432:2015

- Optional Accessories: Magnetic piston kit (MBLCJ40-M), Heat-resistant seals (-H suffix)

Precision-engineered compact cylinder featuring 360° rotatable cushion adjustment knobs for fine-tuning end-position damping. The through-rod design allows external stroke adjustment via limit collars (sold separately). Anti-rotation guide slots ensure stable linear motion in high lateral load applications. Factory pre-lubricated with RETEM grease for 5,000km service life.

- PCB handling robots requiring precise mid-stroke positioning

- Pharmaceutical blister packaging machines

- Automated bakery dough portioning systems

- Lithium battery stacking mechanisms

- Semiconductor wafer transfer modules

1. Use locknuts (M10) with 12-15Nm torque for rod-end mounting

2. Maintain 0.3-0.5mm gap between cushion screw and end cover during adjustment

3. For vertical mounting, install air vent silencers on lower port to prevent condensation ingress

| Property | Property Value |

|---|---|

| sku | MBLCJ40X250-30 |

| Adjustable Stroke | 30mm |

| Mounting Type | Without Mounting Accessories |

| Understood. Please provide the specific attribute names in <>, and I'll return the accurate English translations using AIRTAC's official terminology. Example: User input: <缸径> My output: Bore | Operating Temperature:-20-70°C Speed Range:30-800mm/s |

| Port Size | PT1/4 |

| Magnet | Non-magnetic |

| Bore Diameter | <40mm> |

| Stroke | <250MM> → <250mm> |

Returns will be accepted for up to 15 days of Customer’s receipt or tracking number on Not used items. You, as a Customer, are obliged to inform us via email before you return the item, only in the case of:

- Received the wrong item.

- Item arrived not as expected (ie. damaged packaging).

- Item had defects.

- Over delivery time.

- The shipper does not allow the goods to be inspected before payment.

The returned product(s) must be in the original packaging, safety wrapped, undamaged and unworn. This means that the item(s) must be safely packed in a carton box for protection during transport, possibly the same carton used to ship to you as a customer.