1. Complies with JIS standards;

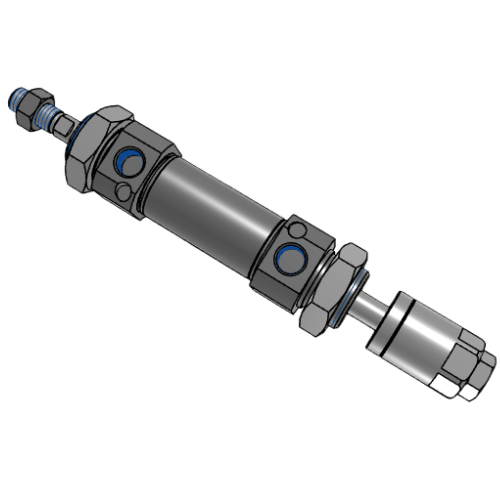

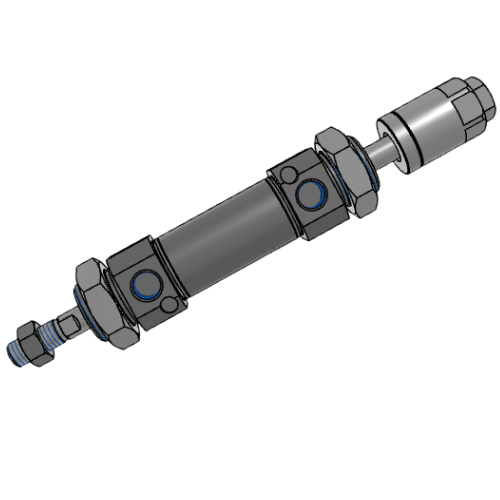

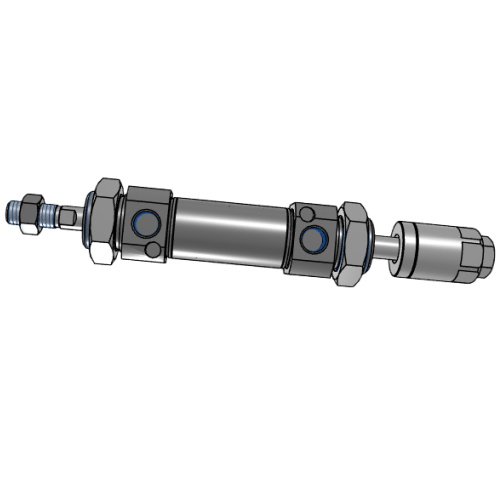

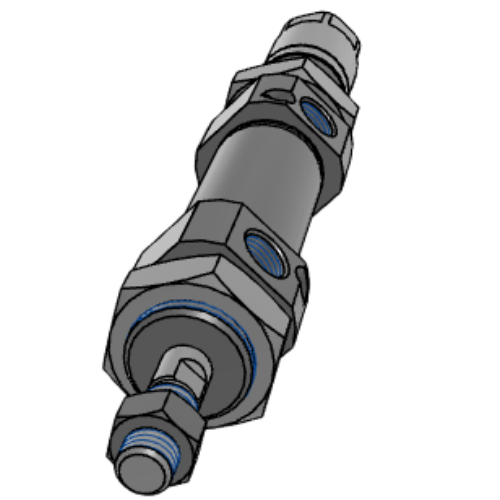

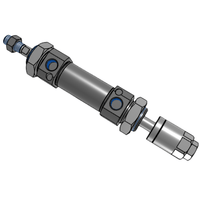

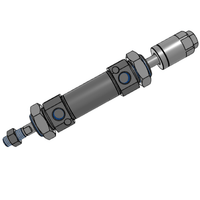

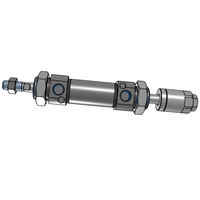

2. Features an asymmetric bidirectional sealing structure with integrated oil reservoir for compact dimensions and enhanced lubrication;

3. Integrated shock-absorbing pads on end caps reduce impact during directional changes;

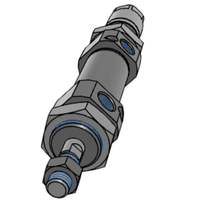

4. Multiple rear cover configurations for enhanced installation flexibility;

5. Crimped clamping mechanism between stainless steel barrel and end caps ensures secure connection;

6. High-precision stainless steel cylinder tube provides excellent strength and corrosion resistance;

7. Compact design offers shorter overall length than ISO 6432 standard cylinders with equivalent bore and stroke;

8. Comprehensive range of cylinder sizes and mounting accessories available for customized solutions.

Category: Adjustable Cylinders | Brand: AIRTAC | Series: MFCJ

AirTAC MFCJ32X300-10 Adjustable Miniature Cylinder Specifications

- Model: MFCJ32X300-10

- Type: Double-acting adjustable cushion cylinder

- Bore size: 32mm (ISO 6432 standard)

- Stroke: 300mm (adjustable ±2mm)

- Mounting: Basic type (MF1)

- Operating pressure: 0.05-1.0 MPa

- Temperature range: -20℃ to 80℃

- Cushion type: Air cushion with adjustable screws

- Port size: M5x0.8 (Rc1/8/NPT1/8 optional)

- Material: Anodized aluminum alloy barrel, stainless steel piston rod

- Rod type: Hard chrome-plated steel

- Position detection: Built-in magnet for sensor mounting

- Repeat positioning accuracy: ±0.5mm

- Max speed: 500-800 mm/s (lubricated)

- Weight: 1.8kg (excluding accessories)

- Dimensions: 300mm(L) × 64mm(W) × 64mm(H) (full extension)

Ultra-compact linear actuator featuring precision-ground rod and auto-switch compatibility. The dual-cushion design with external adjustment screws allows fine-tuning of end-position damping. Nickel-plated end caps provide corrosion resistance in humid environments. Requires ISO VG32 hydraulic oil mist lubrication for optimal performance.

- PCB handling robots in electronics assembly

- Precision clamping mechanisms for medical devices

- Carton folding machine actuators

- Micro-positioning stages in optical equipment

- Automated test equipment (ATE) fixture controls

- Relubricate every 500,000 cycles (continuous operation)

- Inspect cushion seals every 6 months

- Replace rod wiper after 2,000km cumulative travel

| Property | Property Value |

|---|---|

| sku | MFCJ32X300-10 |

| Adjustable Stroke | <10mm> |

| Mounting Type | Without Mounting Accessories |

| Understood. Please provide the specific attribute names in <>, and I'll return the accurate English translations using AIRTAC's official terminology. Example: User input: <缸径> My output: Bore | Operating Temperature:-20-70°C Speed Range:30-800mm/s |

| Port Size | PT1/8 |

| Magnet | Non-magnetic |

| Bore Diameter | <32 mm> |

| Stroke | 300mm |

Returns will be accepted for up to 15 days of Customer’s receipt or tracking number on Not used items. You, as a Customer, are obliged to inform us via email before you return the item, only in the case of:

- Received the wrong item.

- Item arrived not as expected (ie. damaged packaging).

- Item had defects.

- Over delivery time.

- The shipper does not allow the goods to be inspected before payment.

The returned product(s) must be in the original packaging, safety wrapped, undamaged and unworn. This means that the item(s) must be safely packed in a carton box for protection during transport, possibly the same carton used to ship to you as a customer.