1. Complies with JIS standards;

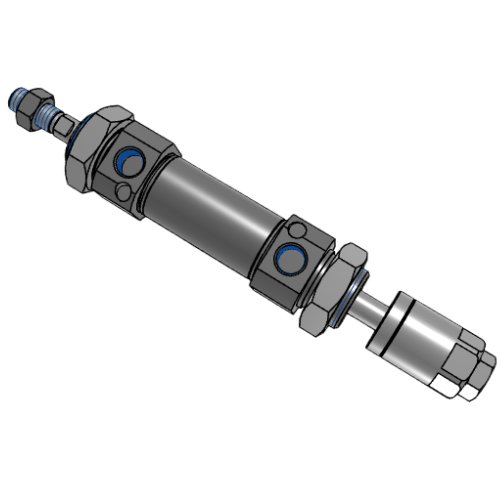

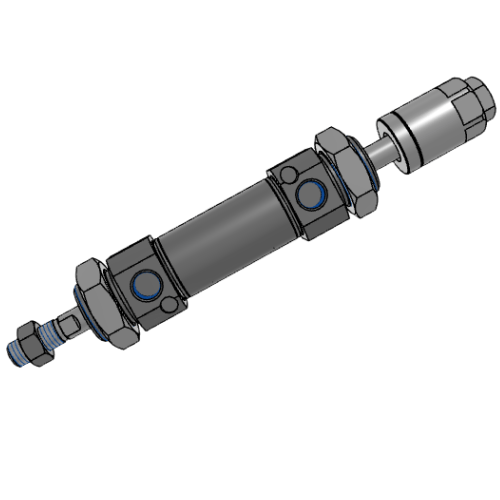

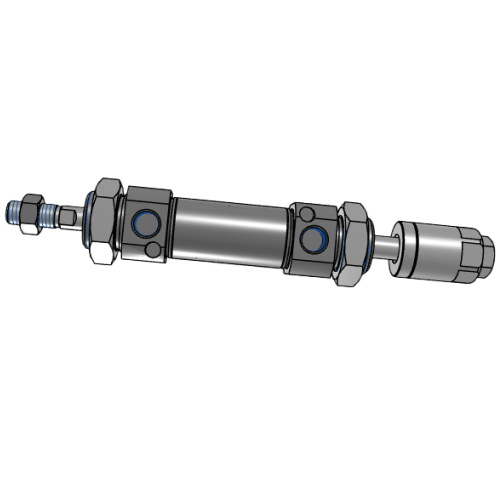

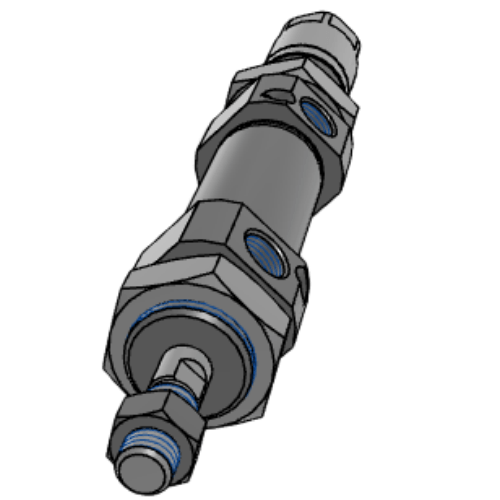

2. Features an asymmetric bidirectional sealing structure with integrated oil reservoir for compact dimensions and enhanced lubrication;

3. Integrated shock-absorbing pads on end caps reduce impact during directional changes;

4. Multiple rear cover configurations for enhanced installation flexibility;

5. Crimped clamping mechanism between stainless steel barrel and end caps ensures secure connection;

6. High-precision stainless steel cylinder tube provides excellent strength and corrosion resistance;

7. Compact design offers shorter overall length than ISO 6432 standard cylinders with equivalent bore and stroke;

8. Comprehensive range of cylinder sizes and mounting accessories available for customized solutions.

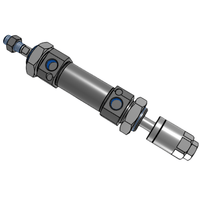

Category: Adjustable Cylinders | Brand: AIRTAC | Series: MFCJ

AirTAC MFCJ32X300-40S Adjustable Mini Cylinder Specifications

- Model: MFCJ32X300-40S

- Type: Double-acting adjustable cushion mini cylinder

- Bore size: 32mm (ISO 6432 standard)

- Stroke: 300mm ±0.8mm tolerance

- Adjustment type: External screw-type cushioning (both ends)

- Operating pressure: 0.15–0.8 MPa (21.7–116 PSI)

- Ambient temperature: -20℃ to 80℃ (non-freezing)

- Cushion stroke: 8mm (adjustable from 0-100% cushioning force)

- Mounting style: Basic type (axial mounting holes)

- Port size: M5x0.8 (Rc1/8" NPT optional)

- Piston rod material: SUS304 stainless steel with hard chrome plating

- Tube material: Aluminum alloy with hard anodized surface

- Seal material: NBR (Nitrile rubber) standard

- Weight: 2.3kg ±5% (excluding accessories)

- Dimensions:

- Total length (L): 437mm (stroke 300 + 137mm base)

- Body diameter: 32mm ±0.5mm

- Mounting hole spacing: 25mm (front) / 40mm (rear)

- Rod end thread: M10x1.25

- Max theoretical thrust: 201N @0.5MPa (72.6N @0.15MPa)

- Max speed: 500mm/s (with proper cushion adjustment)

- Protection rating: IP54 (standard wiper seal)

Ultra-compact profile cylinder (40% smaller than standard ISO cylinders) with precision adjustable cushioning for controlled deceleration. Features corrosion-resistant construction with integrated mounting grooves and auto-lubricating bushings. Requires 5μm filtered air with ISO 8573-1:2010 class 4.2.3 air quality.

- High-density automation cells with space constraints

- Precision material handling in semiconductor manufacturing

- Medical device assembly lines requiring smooth end-stroke control

- Packaging machinery with frequent stroke adjustments

- Robotic end-effector positioning systems

- Maintain 0.5° maximum angular misalignment during mounting

- Apply PTFE-based lubricant every 500km stroke in dry environments

- For vertical mounting, use rod-end locking nut (AN10-M10x1.25 accessory)

- Allow 15mm clearance for cushion adjustment screw operation

| Property | Property Value |

|---|---|

| sku | MFCJ32X300-40S |

| Adjustable Stroke | <40mm> |

| Mounting Type | Without Mounting Accessories |

| Understood. Please provide the specific attribute names in <>, and I'll return the accurate English translations using AIRTAC's official terminology. Example: User input: <缸径> My output: Bore | Operating Temperature:-20-70°C Speed Range:30-800mm/s |

| Port Size | PT1/8 |

| Magnet | S-Magnetic |

| Bore Diameter | <32 mm> |

| Stroke | 300mm |

Returns will be accepted for up to 15 days of Customer’s receipt or tracking number on Not used items. You, as a Customer, are obliged to inform us via email before you return the item, only in the case of:

- Received the wrong item.

- Item arrived not as expected (ie. damaged packaging).

- Item had defects.

- Over delivery time.

- The shipper does not allow the goods to be inspected before payment.

The returned product(s) must be in the original packaging, safety wrapped, undamaged and unworn. This means that the item(s) must be safely packed in a carton box for protection during transport, possibly the same carton used to ship to you as a customer.