2. Features an asymmetric bidirectional sealing structure for piston sealing, offering compact dimensions with integrated oil reservoir functionality;

3. Integrated fixed cushions on both end covers minimize impact during directional changes;

4. Multiple rear cover configurations simplify installation and enhance mounting flexibility;

5. Crimped and wrapped assembly ensures robust connection between stainless steel barrel and end covers;

6. Precision-engineered stainless steel barrel provides exceptional strength and corrosion resistance;

7. MF series achieves shorter overall length than ISO6432 standard cylinders while maintaining identical bore/stroke specifications;

8. Comprehensive range of cylinder variants and mounting accessories available for customized solutions.

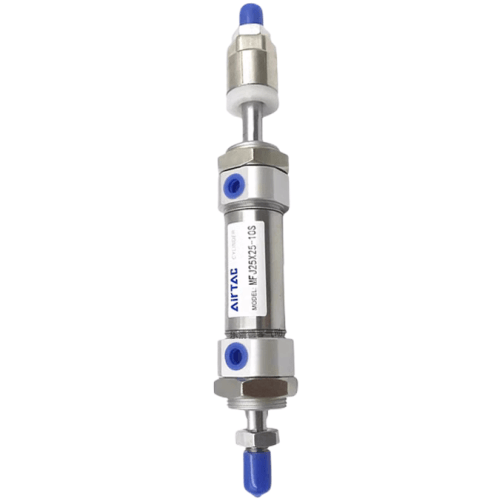

Category: Adjustable Cylinders | Brand: AirTAC | Series: MFJ Adjustable cylinders

AirTAC MFJ Adjustable Miniature Cylinder MFJ20X225-75S Specifications

- Model Code: MFJ20X225-75S

- Bore Size: 20mm (ISO 6432 standard)

- Stroke: 225mm (adjustable ±0.5mm via built-in cushion)

- Operating Pressure: 0.05-0.9 MPa

- Temperature Range: -20℃ to 80℃

- Cushion Type: Adjustable rubber buffer (both ends)

- Mounting Style: Square front flange (ISO 15552 base pattern)

- Port Size: M5x0.8 (dual ports) / Optional G1/8

- Piston Rod: Chrome-plated steel (Ø10mm)

- Cylinder Tube: Aluminum alloy with hard anodized finish

- Seal Material: NBR (Nitrile) with wear-resistant ring

- Weight: 1.25kg (excluding accessories)

- Dimensions:

- Extended Length: 345mm (stroke + end caps)

- Body Width: 42mm (flange to flange)

- Height: 52mm (including mounting base)

- Max Speed: 500mm/s (with cushion adjustment)

- Lubrication: Pre-lubricated (relubrication interval: 2,000km)

Ultra-compact profile cylinder with precision stroke adjustment capability, featuring dual-axis anti-rotation design for stable linear motion. The hardened piston rod and integrated shock absorbers enable high-cycle operations (up to 1.5 million cycles at rated load). Special wear-compensation seals maintain consistent performance under varying temperatures.

- PCB handling robots in electronics assembly

- Dosing valve actuators in medical analyzers

- Paper feed mechanisms in high-speed printers

- Clamping units in micro-injection molding

- Positioning stages in optical alignment systems

- Use alignment jig AKM-20F during mounting to ensure parallelism (≤0.1mm/m)

- Maintain 0.5-1.0mm end play when connecting to guided mechanisms

- For vertical mounting, install air exhaust mist separator APS-4M to prevent lubricant drain

| Property | Property Value |

|---|---|

| sku | MFJ20X225-75S |

| Adjustable Stroke | 75mm |

| Mounting Type | Without Mounting Accessories |

| Understood. Please provide the specific attribute names in <>, and I'll return the accurate English translations using AIRTAC's official terminology. Example: User input: <缸径> My output: Bore | Operating Temperature:-20-70°C Speed Range:30-800mm/s |

| Port Size | PT1/8 |

| Magnet | S-Magnetic |

| Bore Diameter | <20mm> |

| Stroke | 225mm |

Returns will be accepted for up to 15 days of Customer’s receipt or tracking number on Not used items. You, as a Customer, are obliged to inform us via email before you return the item, only in the case of:

- Received the wrong item.

- Item arrived not as expected (ie. damaged packaging).

- Item had defects.

- Over delivery time.

- The shipper does not allow the goods to be inspected before payment.

The returned product(s) must be in the original packaging, safety wrapped, undamaged and unworn. This means that the item(s) must be safely packed in a carton box for protection during transport, possibly the same carton used to ship to you as a customer.