2. Features an asymmetric bidirectional sealing structure for piston sealing, offering compact dimensions with integrated oil reservoir functionality;

3. Integrated fixed cushions on both end covers minimize impact during directional changes;

4. Multiple rear cover configurations simplify installation and enhance mounting flexibility;

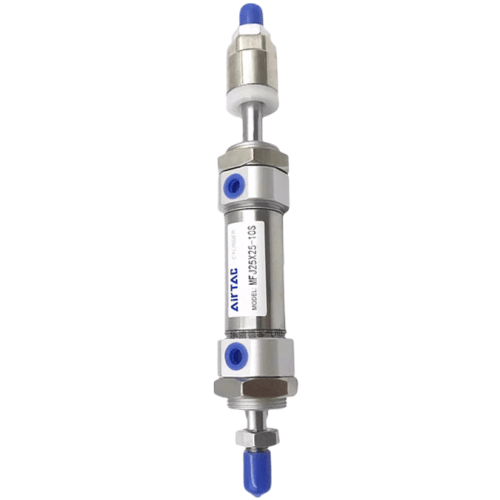

5. Crimped and wrapped assembly ensures robust connection between stainless steel barrel and end covers;

6. Precision-engineered stainless steel barrel provides exceptional strength and corrosion resistance;

7. MF series achieves shorter overall length than ISO6432 standard cylinders while maintaining identical bore/stroke specifications;

8. Comprehensive range of cylinder variants and mounting accessories available for customized solutions.

Category: Adjustable Cylinders | Brand: AirTAC | Series: MFJ Adjustable cylinders

AirTAC MFJ Adjustable Miniature Cylinder MFJ40X60-50 Technical Specifications

- Model Code: MFJ40X60-50

- Type: Double-acting adjustable stroke cylinder

- Bore Size: 40mm (ISO 6432 standard)

- Stroke: 60mm (±5mm adjustable range)

- Operating Pressure: 0.15-0.8 MPa

- Cushioning: External adjustable rubber bumper

- Mounting Styles: Basic front flange (MFJ) with optional foot/rod mounting

- Port Size: PT1/8 (G1/8 adapters available)

- Piston Material: Anodized aluminum alloy

- Rod Material: Stainless steel SUS304

- Seal Type: NBR with wear-resistant ring

- Temperature Range: -20℃ to +80℃

- Weight: 820g ±3% (without accessories)

- Dimensions (L×W×H):

- Body Length: 105mm (excluding rod)

- Full Extended Length: 165mm

- Width: 54mm (mounting flange to rear)

- Height: 40mm (cylinder diameter)

- ISO Certification: Compliant with ISO 6432/DIN ISO 6431

Ultra-compact pneumatic cylinder featuring micro-adjustment capability through its unique threaded rod design. The integrated locknut allows precise stroke positioning (±5mm) without disassembly. Nickel-plated end caps provide enhanced corrosion resistance for humid environments. Includes built-in auto-escape air vents for smooth cushion adjustment.

- PCB handling robots in electronics manufacturing

- Precision clamping mechanisms in CNC tool changers

- Dispenser head actuators in packaging lines

- Micro-positioning in optical lens assembly

- Medical device component insertion systems

1. Use M5x0.8 mounting screws with 22-25N·m torque

2. Maintain 0.3-0.5mm alignment tolerance during rail mounting

3. Lubricate with ISO VG32 hydraulic oil if used below -10℃

4. Stroke adjustment: Loosen locknut, rotate rod (1 full rotation = 1.5mm stroke change)

| Property | Property Value |

|---|---|

| sku | MFJ40X60-50 |

| Adjustable Stroke | <50mm> |

| Mounting Type | Without Mounting Accessories |

| Understood. Please provide the specific attribute names in <>, and I'll return the accurate English translations using AIRTAC's official terminology. Example: User input: <缸径> My output: Bore | Operating Temperature:-20-70°C Speed Range:30-800mm/s |

| Port Size | PT1/4 |

| Magnet | Non-magnetic |

| Bore Diameter | <40mm> |

| Stroke | 60mm |

Returns will be accepted for up to 15 days of Customer’s receipt or tracking number on Not used items. You, as a Customer, are obliged to inform us via email before you return the item, only in the case of:

- Received the wrong item.

- Item arrived not as expected (ie. damaged packaging).

- Item had defects.

- Over delivery time.

- The shipper does not allow the goods to be inspected before payment.

The returned product(s) must be in the original packaging, safety wrapped, undamaged and unworn. This means that the item(s) must be safely packed in a carton box for protection during transport, possibly the same carton used to ship to you as a customer.