2. Integrated fixed cushion rings on front/rear end caps reduce impact shock during directional changes;

3. Multiple rear cap configurations simplify installation flexibility;

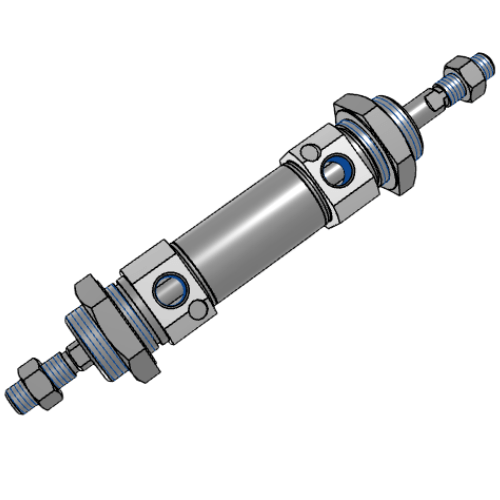

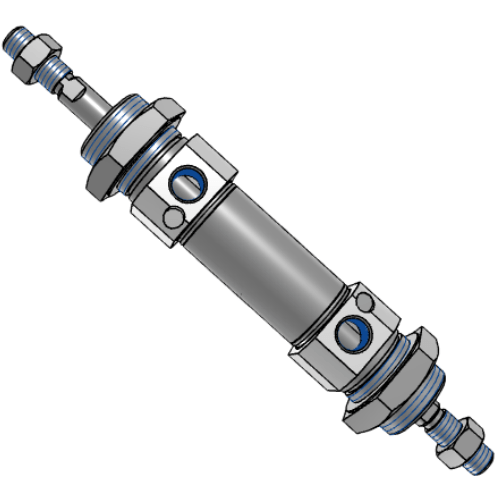

4. Riveted hybrid enclosure structure securely joins end caps to stainless steel cylinder barrel;

5. Stainless steel piston rod and barrel construction ensures reliable operation in mildly corrosive environments;

6. Comprehensive cylinder specifications and mounting accessories available for customized solutions.

Category: Double Rod Cylinders , Brand: AirTAC , Series: MICD

AirTAC MICD Series Pneumatic Cylinder - MICD40X300S Full Specifications

- Model Code: MICD40X300S (Double rod air-cushioned compact cylinder)

- Bore Size: 40mm (ISO 6432 standard)

- Stroke: 300mm (±0.5mm tolerance)

- Operation: Double-acting with adjustable pneumatic cushioning (both ends)

- Operating Pressure: 0.05-0.9 MPa (7-130 PSI)

- Ambient Temperature: -20℃ to +80℃ (NBR seals)/li>

- Port Size: G1/8 (ISO 228-1) with 4xM5 mounting holes

- Piston Rod: Chrome-plated steel ∅12mm (dual rod)

- Cushion Adjustment: 3-stage (0-100% buffer effect)

- Max Speed: 500-800 mm/s (lubricated operation)

- Weight: 1.85 kg (dry, without accessories)

- Dimensions:

- Length: 439mm (stroke 300 + base length)

- Width: 60mm (cylinder body diameter)

- Height: 80mm (including rod ends)

- Rod End Thread: M10x1.25 (male both sides)

- Repeat Positioning Accuracy: ±0.1mm

- ISO Standard: 6432/DIN ISO 6431

Ultra-compact dual-rod cylinder featuring built-in air cushioning for precise end position control. The MICD series combines high rigidity (aluminum alloy body) with anti-rotation guide design, enabling stable linear motion in space-constrained applications. Dual rod configuration allows symmetrical force distribution and optional position sensing via magnetic piston (sensor not included).

- PCB handling robots requiring dual-end force application

- Pharmaceutical tablet press ejection mechanisms

- Automated textile cutting systems with space constraints

- Precision glass panel alignment in display manufacturing

- Food packaging machines needing splash-resistant design (IP54 optional)

- Use alignment jigs during mounting to prevent side load (max 0.5° angular misalignment)

- Maintain 0.5-1mm/m lubricant oil content in air supply (ISO VG32 recommended)

- For vertical mounting: Add 20% safety factor to load calculations

- Cushion needle valve requires 3-5 full test cycles for optimal adjustment

| Property | Property Value |

|---|---|

| sku | MICD40X300S |

| Mounting Type | Without Mounting Accessories |

| Understood. Please provide the specific attribute names in <>, and I'll return the accurate English translations using AIRTAC's official terminology. Example: User input: <缸径> My output: Bore | Operating Temperature:-20-70°C Speed Range:30-800mm/s |

| Port Size | PT1/4 |

| Magnet | S-Magnetic |

| Cushion Type | Bumper Pad |

| Bore Diameter | <40mm> |

| Stroke | 300mm |

Returns will be accepted for up to 15 days of Customer’s receipt or tracking number on Not used items. You, as a Customer, are obliged to inform us via email before you return the item, only in the case of:

- Received the wrong item.

- Item arrived not as expected (ie. damaged packaging).

- Item had defects.

- Over delivery time.

- The shipper does not allow the goods to be inspected before payment.

The returned product(s) must be in the original packaging, safety wrapped, undamaged and unworn. This means that the item(s) must be safely packed in a carton box for protection during transport, possibly the same carton used to ship to you as a customer.