Description

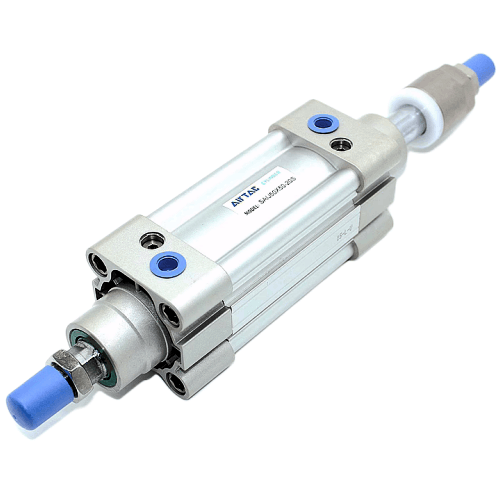

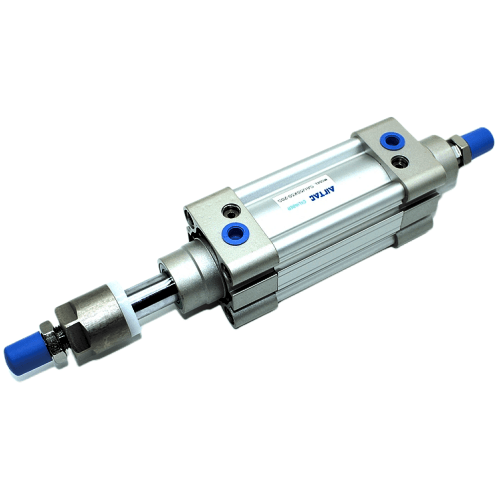

SAIJ63 Adjustable Cylinder

1. ISO15552 (formerly ISO6431) standard compliant cylinder

2. Features asymmetric bidirectional sealing structure with compact dimensions and integrated oil reservoir function in piston sealing

3. H-shaped aluminum tubing with rodless design enhances corrosion resistance; External sensor mounting grooves enable quick installation

4. Smooth and stable cushion adjustment mechanism

5. Multiple cylinder specifications and mounting accessories available for versatile applications

6. High-temperature resistant sealing materials support operating temperature range of 0~150℃

Category: Standard Cylinders | Brand: AIRTAC | Series: SAIJ63

Installation guidelines:

Installation guidelines:

1. Use alignment jig (AIR-AL63) during mounting to ensure parallelism

2. Apply Loctite 243 to rod threads when attaching accessories

3. Minimum 100mm clearance required for full stroke adjustment

4. Lubricate with ISO VG32 turbine oil if used in high-cycle applications (>50 CPM)

1. ISO15552 (formerly ISO6431) standard compliant cylinder

2. Features asymmetric bidirectional sealing structure with compact dimensions and integrated oil reservoir function in piston sealing

3. H-shaped aluminum tubing with rodless design enhances corrosion resistance; External sensor mounting grooves enable quick installation

4. Smooth and stable cushion adjustment mechanism

5. Multiple cylinder specifications and mounting accessories available for versatile applications

6. High-temperature resistant sealing materials support operating temperature range of 0~150℃

Category: Standard Cylinders | Brand: AIRTAC | Series: SAIJ63

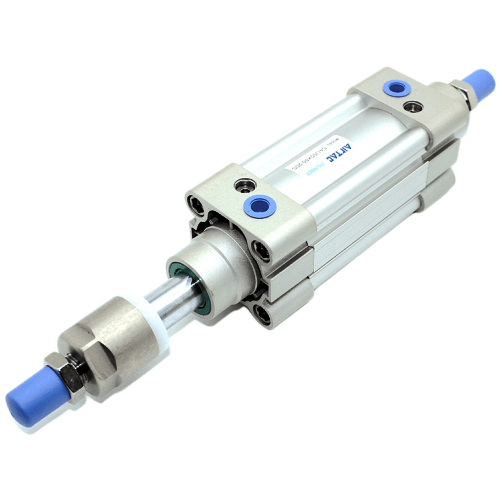

AirTAC SAIJ63AX200-30S Adjustable Cylinder Specifications

- Model Decode: SAIJ63-AX200-30S

- SAIJ: Standard adjustable cylinder series

- 63: 63mm bore size

- AX: Adjustable stroke mechanism

- 200: 200mm maximum stroke length

- 30S: Cushion type (dual adjustable) + specific mounting variant

- Operating pressure: 0.1-0.9 MPa (14.5-130.5 PSI)

- Temperature range: -20℃ to 80℃ (non-freezing conditions)

- Cushioning: Adjustable air cushion at both ends

- Mounting type: Front flange (MF1) with standard ISO 15552 mounting pattern

- Port size: G1/4 (BSPP thread)

- Piston rod thread: M20×1.5 (external)

- Materials:

- Tube: Aluminum alloy with hard anodized surface

- Piston rod: Chrome-plated stainless steel (SUS304)

- End caps: Die-cast aluminum

- Seals: NBR (standard), optional FKM available

- Weight: 2.5kg ±3% (without accessories)

- Dimensions:

- Total length: 300mm (at mid-stroke position)

- Stroke adjustment range: 50-200mm

- Body diameter: 63mm ±0.5mm

- Mounting flange dimensions: 80×40mm (4×Ø6.6 mounting holes)

- Lubrication: Pre-lubricated (relubrication interval: 3,000km travel distance)

- ISO certification: Complies with ISO 15552 (formerly ISO 6431)

High-precision adjustable stroke cylinder featuring micro-adjustment locking mechanism (±0.5mm repeat accuracy). The dual cushioning system minimizes end-impact noise below 75dB(A). Magnetic piston version optional (add "-M" suffix to model number).

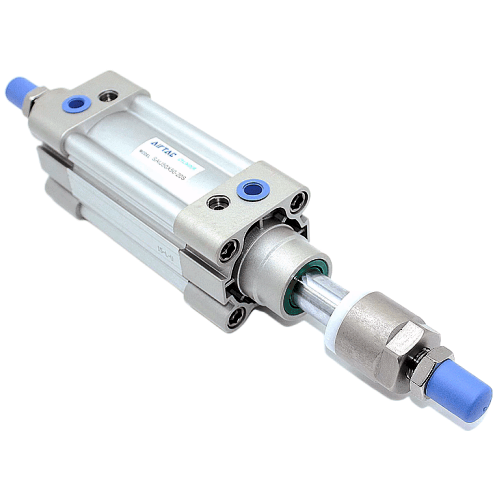

Industrial Applications:

- Variable height positioning in automotive assembly jigs

- Press-fit operations with adjustable depth control

- Packaging line product ejection systems

- Plastic injection molding machine core-pull mechanisms

- Semiconductor wafer handling equipment

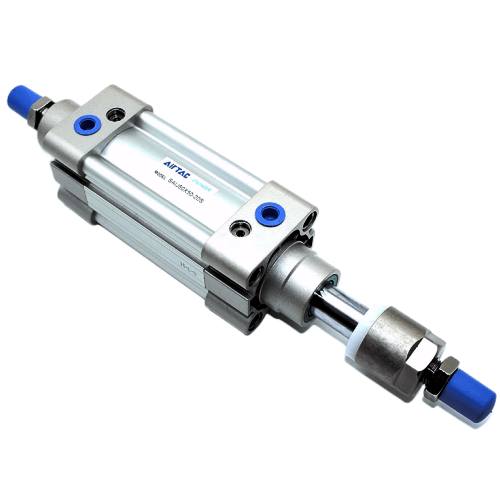

1. Use alignment jig (AIR-AL63) during mounting to ensure parallelism

2. Apply Loctite 243 to rod threads when attaching accessories

3. Minimum 100mm clearance required for full stroke adjustment

4. Lubricate with ISO VG32 turbine oil if used in high-cycle applications (>50 CPM)

| Property | Property Value |

|---|---|

| sku | SAIJ63AX200-30S |

| Adjustable Stroke | 30mm |

| Seal Material | Polyurethane |

| Understood. Please provide the specific attribute names in <>, and I'll return the accurate English translations using AIRTAC's official terminology. Example: User input: <缸径> My output: Bore | Operating Temperature:-20-70°C Speed Range:30-800mm/s |

| Port Size | PT3/8 |

| Magnet | S-Magnetic |

| Bore Diameter | 63mm |

| Stroke | <200mm> |

Shipping policies

Returns will be accepted for up to 15 days of Customer’s receipt or tracking number on Not used items. You, as a Customer, are obliged to inform us via email before you return the item, only in the case of:

- Received the wrong item.

- Item arrived not as expected (ie. damaged packaging).

- Item had defects.

- Over delivery time.

- The shipper does not allow the goods to be inspected before payment.

The returned product(s) must be in the original packaging, safety wrapped, undamaged and unworn. This means that the item(s) must be safely packed in a carton box for protection during transport, possibly the same carton used to ship to you as a customer.

Reviews

Recently Viewed

Explore your recently viewed items, blending quality and style for a refined living experience.