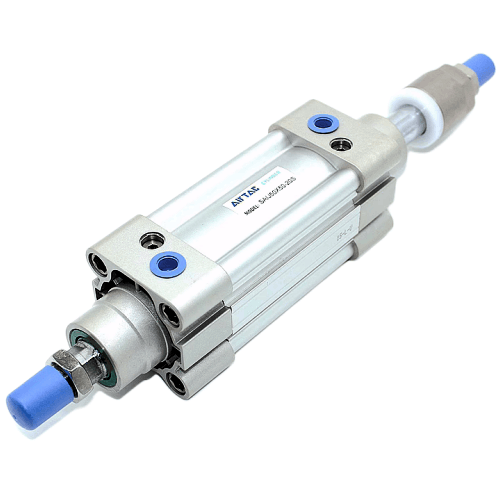

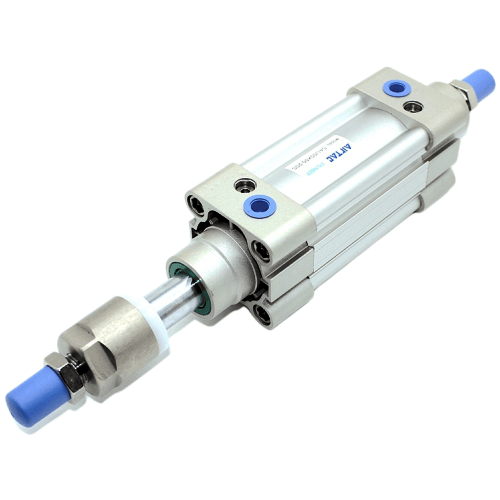

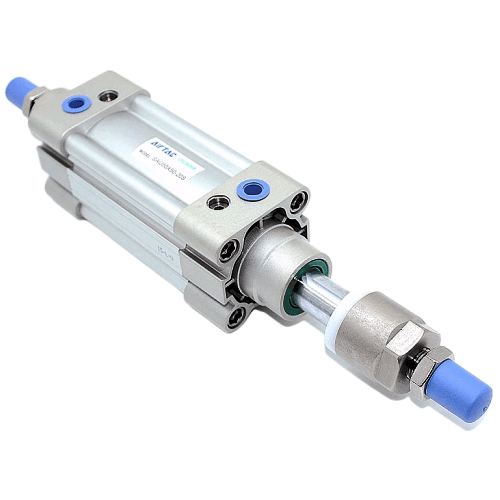

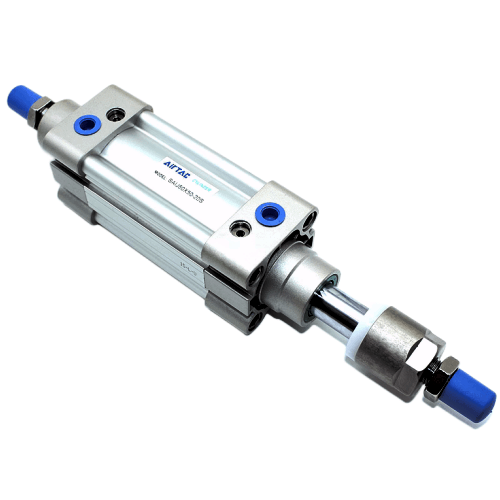

1. ISO15552 (formerly ISO6431) standard compliant cylinder

2. Features asymmetric bidirectional sealing structure with compact dimensions and integrated oil reservoir function in piston sealing

3. H-shaped aluminum tubing with rodless design enhances corrosion resistance; External sensor mounting grooves enable quick installation

4. Smooth and stable cushion adjustment mechanism

5. Multiple cylinder specifications and mounting accessories available for versatile applications

6. High-temperature resistant sealing materials support operating temperature range of 0~150℃

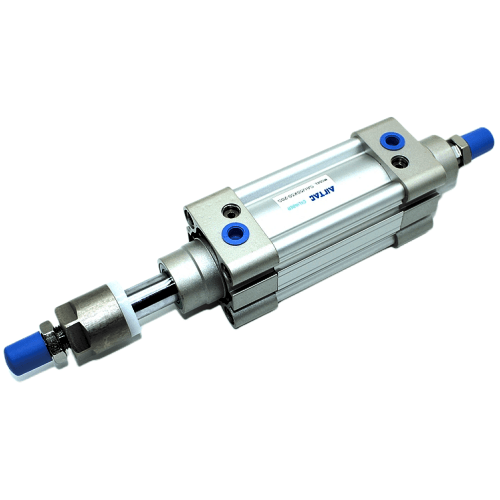

Category: Standard Cylinders | Brand: AIRTAC | Series: SAIJ63

AirTAC SAIJ63 Adjustable Stroke Cylinder SAIJ63X900-30 Technical Details

- Model Code: SAIJ63X900-30

- Cylinder Type: Double-acting adjustable stroke

- Bore Size: Ø63mm (±0.08mm tolerance)

- Full Stroke: 900mm (35.43")

- Adjustable Range: 30mm incremental adjustment (870-900mm)

- Operating Pressure: 0.1-0.9 MPa (14.5-130.5 PSI)

- Temperature Range: -20℃ to 80℃ (-4°F to 176°F)

- Cushioning: Adjustable pneumatic cushion at both ends

- Mounting Style: MF1 (Square base with front flange)

- Port Size: PT1/4 (G1/4 optional)

- Rod Material: Chrome-plated steel (C1032)

- Tube Material: Aluminum alloy (Al6063-T5) with hard anodizing

- Seal Type: NBR (Nitrile) wiper & piston seals

- Weight: 5.2kg (11.46 lbs) ±3%

- Dimensions: 1130mm(L) × 100mm(W) × 100mm(H)

- Rod Thread: M16×1.5 external thread (stainless steel)

- Repeat Accuracy: ±0.5mm (with proper guidance system)

The SAIJ63X900-30 features a unique telescopic stroke adjustment mechanism with locking collar, enabling precise stroke reduction without disassembly. Its double-wall construction with corrosion-resistant coating makes it suitable for humid environments. The cylinder incorporates a wear-compensation system that maintains seal integrity through 5,000km cumulative stroke life.

- Variable height positioning in automotive welding jigs

- Palletizing systems requiring adjustable stacking heights

- Plastic injection molding machine ejectors

- Paper converting equipment with variable cut lengths

- Glass tempering furnace door actuators

1. Use M6 mounting bolts (8.8 grade min) with Loctite 243

2. Maintain ≤0.1mm/m alignment tolerance during installation

3. Pre-lubricate with ISO VG32 hydraulic oil before initial use

4. Install 40μm filter-regulator-lubricator (FRL) unit upstream

a) Depressurize system and lockout energy sources

b) Loosen four M5 set screws on adjustment collar

c) Rotate collar clockwise to reduce stroke (1 full rotation = 2.5mm adjustment)

d) Re-tighten set screws to 3.5Nm torque in cross pattern

| Property | Property Value |

|---|---|

| sku | SAIJ63X900-30 |

| Adjustable Stroke | 30mm |

| Seal Material | Polyurethane |

| Understood. Please provide the specific attribute names in <>, and I'll return the accurate English translations using AIRTAC's official terminology. Example: User input: <缸径> My output: Bore | Operating Temperature:-20-70°C Speed Range:30-800mm/s |

| Port Size | PT3/8 |

| Magnet | Non-magnetic |

| Bore Diameter | 63mm |

| Stroke | <900mm> |

Returns will be accepted for up to 15 days of Customer’s receipt or tracking number on Not used items. You, as a Customer, are obliged to inform us via email before you return the item, only in the case of:

- Received the wrong item.

- Item arrived not as expected (ie. damaged packaging).

- Item had defects.

- Over delivery time.

- The shipper does not allow the goods to be inspected before payment.

The returned product(s) must be in the original packaging, safety wrapped, undamaged and unworn. This means that the item(s) must be safely packed in a carton box for protection during transport, possibly the same carton used to ship to you as a customer.